A steel blind flange stands out as an essential element among the intricate network of industrial pipe system operations and serves diverse roles and functions across various industries. From facilitating pipeline closures to providing access points for maintenance, blind flanges play a pivotal role in fluid control systems. This guide explores the world of blind flanges and explains their purpose, types, and applications.

Understanding Blind Flanges:

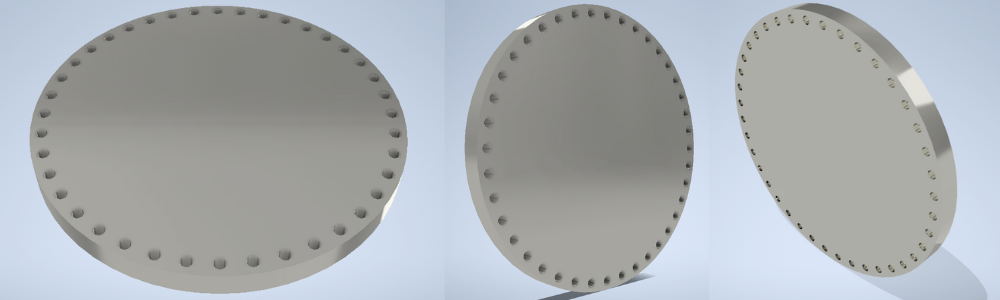

Blind flanges, also known as blanking or flat face flanges, are solid disks that block off or seal the end of a piping system or vessel opening. Unlike other types of flanges that feature an inner borehole with bolt holes for connection, blind flanges are smooth and lack an inner borehole but share the same bolt holes for connection to a piping system. They are typically installed at the end of a pipeline or at points where future expansion or maintenance may be necessary.

Purpose and Functions:

The primary purpose of blind flanges is to securely close off the ends of pipes, valves, or pressure vessel openings. By doing so, they prevent the flow of fluids or gases through the system. Blind flanges are commonly employed in applications where temporary or permanent closure of pipelines is required, such as during maintenance, repairs, or system isolation.

Types of Blind Flanges:

- Raised Face Blind Flanges: Raised face blind flanges feature a raised ring or face around the borehole, which allows for easy alignment and sealing when bolted to a mating flange. The raised face helps create a tight seal, minimizing the risk of leaks.

- Flat-Face Blind Flanges: Flat-face blind flanges have a smooth and flat surface without any protrusions. They are suitable for applications where the mating flange or equipment has a flat face.

- Ring Type Joint (RTJ) Blind Flanges: RTJ blind flanges are designed to accommodate ring-type joint gaskets, which provide a reliable seal under high-pressure and high-temperature conditions. These flanges are commonly used in critical applications within the oil and gas industry.

- Customized Blind Flanges: Besides standard designs, blind flanges can be customized to meet specific requirements, such as non-standard sizes, materials, or pressure ratings. Customization ensures optimal performance and compatibility with existing systems.

Do You Need a Custom Blind Flange?

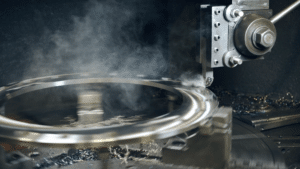

At API International, Inc., we understand that every industrial application has unique requirements. To meet our customers’ needs, we offer custom blind flange manufacturing capabilities. Our experienced engineers and technicians collaborate closely with clients to design and produce blind flanges tailored to their specifications.

Whether it’s non-standard sizes, specialized materials, or unique pressure ratings, we have the expertise and resources to deliver custom solutions that meet the most demanding industry standards. Our state-of-the-art manufacturing facilities have advanced machinery and quality control systems to ensure precision and consistency in every blind flange we produce.

We prioritize quality, reliability, and customer satisfaction from initial concept to final product delivery. Businesses can optimize their operations, improve efficiency, and minimize downtime by leveraging our custom manufacturing capabilities. Whether you require a single prototype or large-scale production runs, API International, Inc. is your trusted partner for custom blind flanges that exceed expectations.

Blind Flange Materials and Construction:

A blind flange is typically manufactured from various materials, including carbon steel, stainless steel, alloy steel, and non-ferrous metals such as copper, brass, or bronze. The choice of material depends on factors such as the fluid or gas being transported, operating conditions, and environmental factors. For example, stainless steel blind flanges are preferred for corrosive environments, while a carbon steel blind flange can offer excellent strength and durability in high-pressure applications.

Applications of a Blind Flange:

Blind flanges find widespread use across numerous industries, including:

- Oil and Gas: Blind flanges are used in oil refineries, petrochemical plants, and offshore platforms for system isolation, pressure testing, and equipment maintenance.

- Chemical Processing: In chemical processing facilities, blind flanges seal off pipelines during batch processing, cleaning, or equipment inspections.

- Water Treatment: In municipal water treatment plants and industrial facilities, blind flanges are employed in piping systems to control flow and isolate sections for repairs or upgrades.

- Power Generation: In power plants, blind flanges are utilized in steam, water, and gas pipelines to temporarily or permanently close them during maintenance shutdowns or equipment replacement.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, blind flanges seal off ductwork or piping branches to control airflow and pressure distribution.

Examples of Blind Flange Application:

- Offshore Drilling Rig: During routine maintenance on an offshore drilling rig, blind flanges seal off sections of the piping system, allowing technicians to work safely without the risk of fluid leakage.

- Chemical Plant Shutdown: When a plant is shut down for equipment inspection and maintenance, blind flanges isolate specific process units, ensuring personnel safety and preventing product contamination.

- Water Pipeline Repair: In a municipal water treatment facility, blind flanges block off pipeline sections undergoing repair or replacement, minimizing service disruptions for consumers.

With their versatility, durability, and customizable options, a blind flange can cater to various applications across diverse industries. By understanding the different types, materials, and applications of blind flanges, engineers and operators can ensure their systems’ efficiency and safe operation.

As a leading supplier of industrial fittings, API International, Inc. offers a comprehensive range of blind flanges backed by quality assurance and technical expertise to meet our customers’ specific needs. If you have additional questions about your project requirements, reach out to our team! We will pair you with a dedicated account manager who can help you find the flanges you need for your project.