Our machine shop enables API to manufacture custom flanges and other products that meet a wide variety of specifications that utilize AIS, import, and exotic materials. We also support fast turn modifications to our stock items in order to meet customer needs. Whether you have a CAD drawing or sample that needs to be reverse engineered, we can work with you on prototyping, production quantity manufacturing and even warehousing product.

Experience with a wide variety of products, sizes, materials and specifications.

Short lead times that allow you to get products to customers when they need them.

QC personnel work with modern technology to verify that all of our products meet your project requirements and abide by current regulations.

Our machine shop’s vast knowledge of tooling and fixturing can help reduce your production cost, especially on your high volume products.

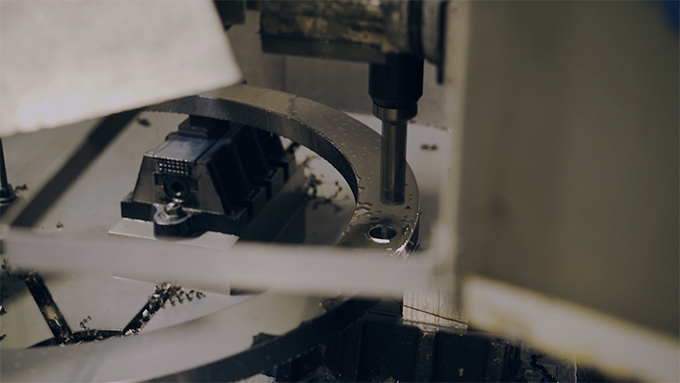

Milling

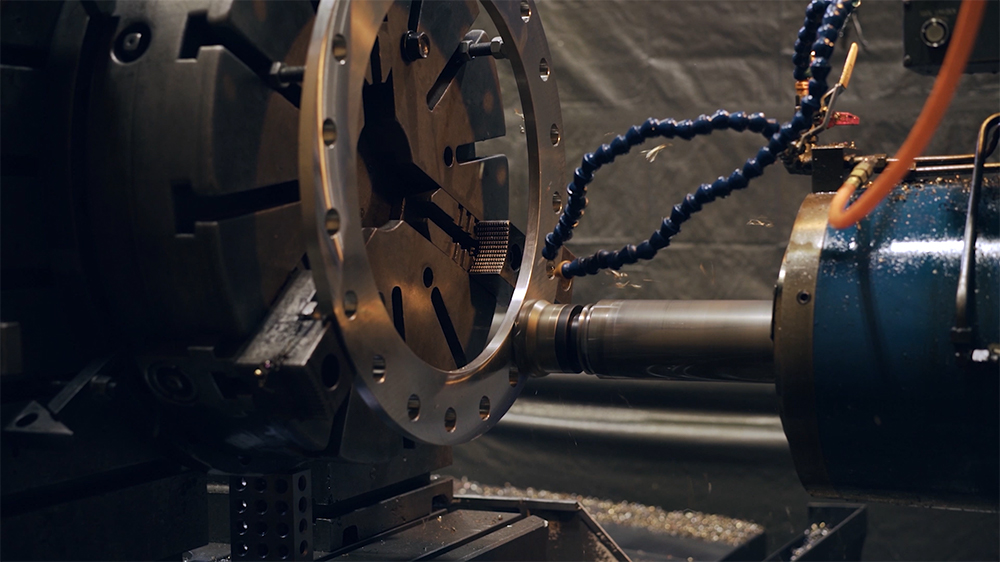

Turning

Materials

*Tooling can be added quickly in order to work with almost any material

Tolerances

| Part Size (max) | Tolerance (inches) |

|---|---|

| 21″ | ± 0.001 |

| 42″ | ± 0.010 |

| 60″ | ± 0.031 |

| 118″ | ± 0.063 |

Helpful Details

Here are some of the machines that allow us to manufacture custom flanges and other fittings. They can make modifications to standard parts, like overboring, counterboring, different bolt holes and surface finishes.

API International, Inc.

12505 SW Herman Road

Tualatin, OR 97062

API International, Inc. | All rights reserved. | Terms & Conditions | Privacy Policy