This blog post will cover the most common flange types used in today’s industrial applications. Flanges are essential components in industrial applications. Even though there are many different types of flanges, they all share a common goal- to connect piping systems together. Let’s explore the specifics of the seven most popular flange types, their unique characteristics, and their practical uses that make them essential in various industries.

Weld Neck Flange:

Weld neck flanges perform exceptionally well in high-pressure systems. They are one of the most common flange types. Their long neck allows a seamless butt weld directly onto the pipe, leaving a smooth connection. Because of this, they are perfect for use in sectors like the oil and gas industry, where dependability under high pressure is crucial. This style of flange connection is almost exclusively used in larger diameters and higher-pressure classifications.

Slip-on Flange:

The simplicity of installing slip-on flanges makes them popular among manufacturers and fabricators. Because the slip-on flange lacks a weld bevel and permits pipe length adjustment in relation to flange location, it is an easy and excellent substitute for a weld neck. The matching pipe will have plenty of room in the slip-on’s bore. This extra room provides sufficient workspace for the fabricator and welder to connect. They are frequently used in sectors like shipbuilding and construction that demand quick and effective setup. This kind of flange is widely used in applications with lower pressure. A hub found on most slip-on style flanges frequently resembles a raised face in terms of dimensions. In cases where space is restricted, and the application permits a “ring style” slip-on, it can be outfitted without a hub. A ring-style slip-on without a hub still qualifies as a slip-on flange and can be recognized as you see fit, even if the hub style is more frequently used when discussing slip-ons. Higher-pressure class slip-ons are commonly designed with a lap joint height for improved attachment.

Socket-weld Flange:

Socket-weld flanges are resilient to high pressure and temperatures, benefiting the power generation and chemical processing industries. With a counterbore in the middle to enable a clean pipe weld into the socket, socket weld flanges are less popular but no less effective connection for flanges that require less total available space than a typical weld neck flange. These are typically supplied in smaller nominal pipe sizes, and when needed, they’re an excellent substitute for slip-on and weld necks. If the fluid is not corrosive and the pressure class is relatively low, a socket weld may be chosen for an assembly with limited space or extremely high-temperature duty.

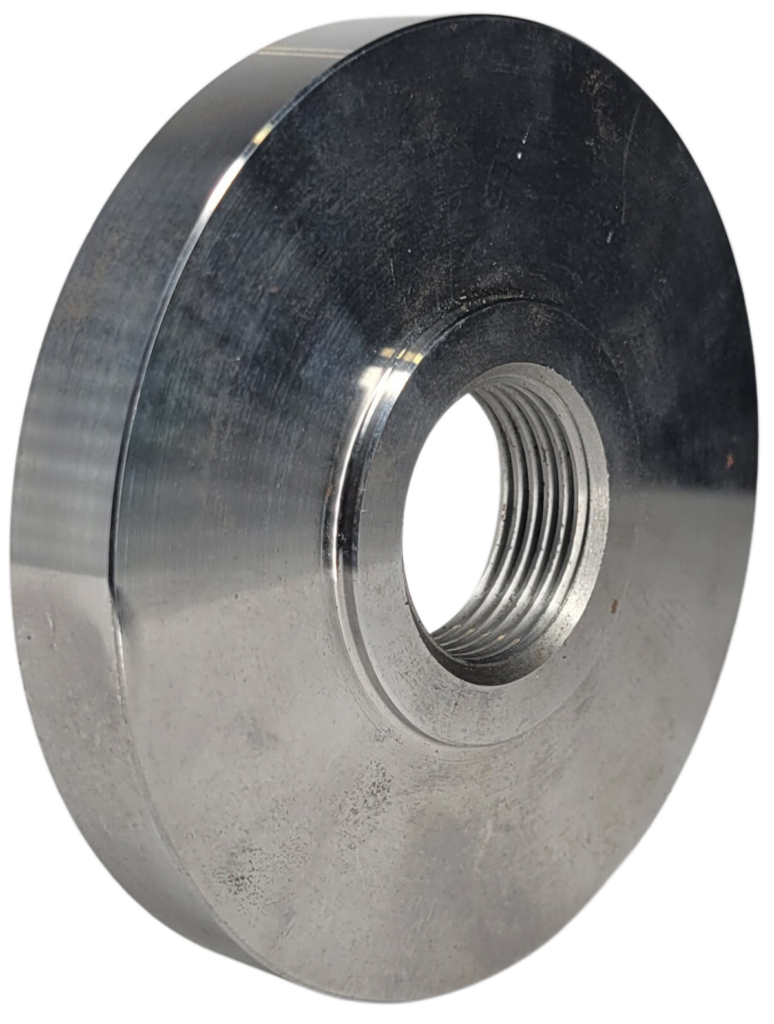

Threaded Flange:

Threaded flanges are easy to install and perform well in low-pressure applications. They are a vital component in piping systems and other environments where it’s essential to maintain a tight seal without doing a lot of welding. Threaded flanges have a female NPT thread in the middle for connecting to male NPT threaded piping. They are also sometimes called companion flanges, screw flanges, or NPT flanges. Threaded flanges are frequently used to create reduced connections. In addition to the basic NPT form, as defined by the ASME B16.5 specification, several thread styles can be machined.

Blind Flange:

Blind flanges are essential for closing off portions of a pipe system. Blind flanges are dependable barriers in petrochemical and other hazardous material-related industries, guaranteeing worker safety and stopping leaks during emergencies or maintenance. Blind flanges with raised faces frequently have a slight indentation in the middle, as seen in B16.1 and other industry standard cast steel requirements from decades ago. This recess allowed the pipe end to mate with the connecting flange and for a seal to form between the blind and the connecting flange. To produce a dished head formation at the top of the flange, the more oversized OD blind flanges have a concave recess through the blind’s body. For the most part, blind flanges won’t be produced in these forms because the earlier cast iron specification is somewhat outdated. Instead, go for a modern blind flange with or without a hub.

Lap Joint Flange:

A Lap joint flange makes the list among the other common flange types. They are also known as Backup flanges, Loose Ring flanges, Loose Hubbed flanges, and Van Stone flanges. Easily disassembled, lap joint flanges offer flexibility and are perfect for industries like the food and beverage industry that need regular maintenance or adjustments. The hubs can be adjusted to your specifications and are usually taller than a slip-on design. Higher-pressure class slip-ons are frequently designed with a lap joint height for improved attachment. Customers will occasionally choose a slip-on intended to resemble a lap joint with a machined hub if the hub height is not an issue and a lap joint is not easily accessible. Industrial flanges are used in various industries, such as structural applications and plumbing. Rolled angle rings and lap joint flanges are two parts that are essential to many processes. The main distinction between rolling angle rings and lap joint flanges is that the latter is exclusively offered in a butt-weld arrangement. Conversely, lap joint flanges are available in slip-on and butt-weld varieties. The backing flange on a lap joint flange can rotate, unlike the backing flange on a rolled angle ring.

Custom Flange:

Contrary to the name, custom flanges are common flange types with many applications and uses across various industries. Our machine shop makes it possible to use AIS and import materials to build products that satisfy various specifications. We also facilitate quick changes to our stock of goods to serve our customers better. Whether you need to reverse engineer a sample or a CAD drawing, we can work with you on prototypes, production quantity manufacturing, and even product warehousing.

API’s Machining Capabilities:

- Machining inner diameter, outer diameter, gasket face, chamfers, and tapers up to 120″ outer diameter

- Single point threading of inner and outer diameter with standard or metric pitch

- Straight turning, tapers, and angles of inner and outer diameter face

- Profile milling, facing, contouring, pocketing, boring and threading

- Milling straight and tapered pipe threads

- Single-part or large production orders

- Bolt-hole drilling up to 3″ diameter

- Turning shafts up to 60″ in length

- Steel, Aluminum, Duplex, Super Duplex, Alloy 20, and other exotic metals

Each flange type has a unique role to play. At API International, Inc., we pride ourselves on offering a diverse range of fittings, including these essential flange types, to meet the specific needs of various industries. Contact our sales team if you have questions or need a quote. Our dedicated sales team staff are ready to help you find the industrial fittings you need for your project.