In the dynamic energy and power generation industry, operational efficiency, and reliability reign supreme. Rubber expansion joints emerge as unassuming yet indispensable players that significantly influence pipelines and system performance. These rubber fittings manage stress, vibration, and misalignment, elevating operational proficiency. Let’s explore the many applications, functions, and technical insights of these flexible fittings within the energy and power generation industry.

API International stands at the forefront, stocking an extensive array of expansion joints tailored to fulfill diverse exhaust system prerequisites. From carbon steel and stainless steel single or twin sphere rubber expansion joints, to control rod units and braided pump connectors, our offerings cover the entire spectrum.

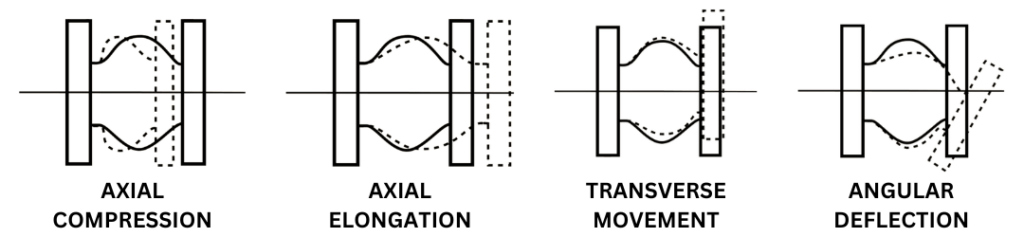

Rubber expansion joints, also called flexible connectors, prove their mettle as adaptable components inserted into pipelines to counteract movements stemming from thermal expansion, contraction, vibration, or misalignment. Comprising layers of rubber and reinforcement materials, they are engineered to withstand the demanding conditions within in energy and power generation facilities.

Rubber expansion joints demonstrate their worth across the energy and power generation industries by augmenting system reliability, mitigating stress, and accommodating movements stemming from a range of factors. Their versatility shines in many applications, from thermal power plants to renewable energy facilities. A comprehensive understanding of the technical facets and benefits of rubber expansion joints empowers energy companies to render their operations smoother, more efficient, and markedly more dependable.

For all your rubber expansion joint requirements, navigate our diverse range of products at API International. Find tailored solutions compatible with your energy, power generation, and oil system demands. Contact us today and get connected with a dedicated account manager!

API International, Inc.

12505 SW Herman Road

Tualatin, OR 97062

API International, Inc. | All rights reserved. | Terms & Conditions | Privacy Policy