Precision and efficiency emerge as the cornerstones of excellence in the dynamic realm of HVAC (Heating, Ventilation, and Air Conditioning). To unlock optimal performance, more professionals are turning to custom-machined and OEM products. These tailor-made components serve as the linchpin in enhancing HVAC systems’ efficacy, resilience, and energy efficiency. This discourse embarks on an expedition into the gamut of applications, advantages, and technical intricacies intrinsic to custom-machined products within the HVAC industry.

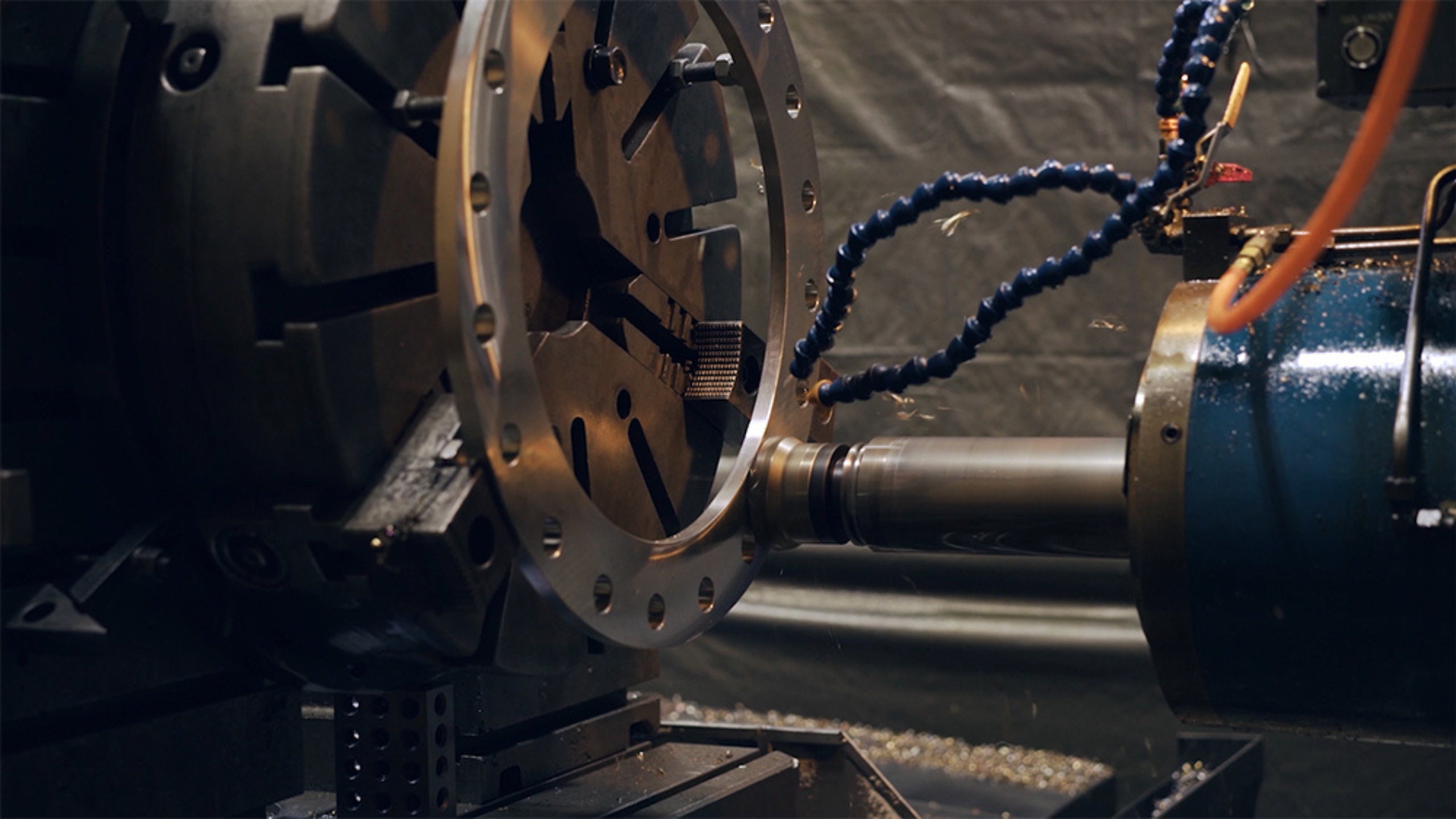

Our machine shop enables API to manufacture product that meets a wide variety of specifications utilizing American Iron and Steel Institute (AIS) and Import materials. We also support fast turn modifications to our stock items in order to meet customer needs. Whether you have a CAD drawing or sample that needs to be reverse engineered, we can work with you on prototyping, production quantity manufacturing and even warehousing product.

Custom-machined products have uniquely contributed to enhanced performance, energy efficiency, and system longevity within HVAC systems. Whether it is precision heat exchangers, intricate valves, or specialized ducting components, custom solutions are crucial to obtaining optimal HVAC functionality. HVAC professionals and engineers are poised to propel their systems to peak performance and efficiency by assimilating a deep understanding of their applications, benefits, and technical complexities.

For all your Custom Machining and OEM project requirements, navigate our diverse range of products at API International. Find tailored solutions compatible with your HVAC system's demands. Contact us today and get connected with a dedicated account manager!

API International, Inc.

12505 SW Herman Road

Tualatin, OR 97062

API International, Inc. | All rights reserved. | Terms & Conditions | Privacy Policy