Rubber expansion joints are used across a multitude of industries, bringing flexibility and durability to pipe systems. These joints are indispensable in maritime environments, countering constant movement and harsh conditions. Let’s explore rubber expansion joints’ applications in the maritime sector, shedding light on their uses, advantages, and technical aspects.

API International stands at the forefront, stocking an extensive array of expansion joints tailored to fulfill diverse exhaust system prerequisites. From carbon steel and stainless steel single or twin sphere rubber expansion joints, to control rod units and braided pump connectors, our offerings cover the entire spectrum.

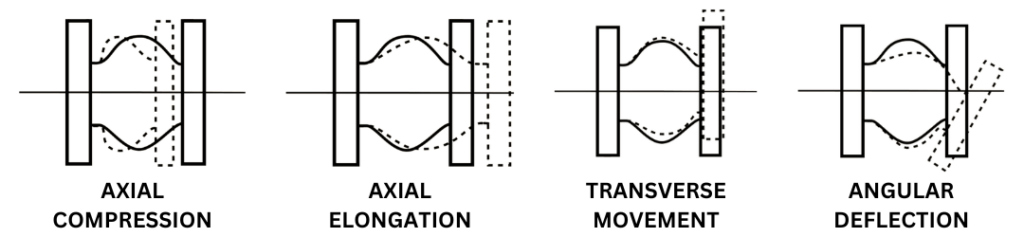

Rubber expansion joints absorb thermal expansion, vibration, and movement in pipe systems. Layers of rubber and reinforcing materials create versatile components that endure extreme conditions.

Rubber expansion joints safeguard piping integrity in the maritime and maritime industry. From shipbuilding to offshore platforms, their applications span vital functions, including vibration absorption, temperature regulation, and fluid control. By grasping their advantages and technical aspects, maritime professionals can confidently integrate these joints, enhancing efficiency and safety in their systems. For top-quality rubber expansion joints tailored to marine needs, rely on API International.

For all your Flexible Expansion Joint requirements, navigate our diverse range of products at API International. Find tailored solutions compatible with your marine and maritime system demands. Contact us today and get connected with a dedicated account manager!

API International, Inc.

12505 SW Herman Road

Tualatin, OR 97062

API International, Inc. | All rights reserved. | Terms & Conditions | Privacy Policy