While rubber expansion joints may appear unassuming, their applications and intricacies profoundly impact the efficiency and safety of mining operations. API stocks Single-Sphere and Twin Sphere Molded Rubber Expansion Joints in both carbon steel and stainless steel. We also sell Control Rod Units and Split Retaining Rings to complete the package. With DIN expansion joints as an option, we are sure that you will find the product you need at API International.

API International stands at the forefront, stocking an extensive array of expansion joints tailored to fulfill diverse mining system requirements. From carbon steel and stainless steel single or twin sphere rubber expansion joints, to control rod units and braided pump connectors, our offerings cover the entire spectrum.

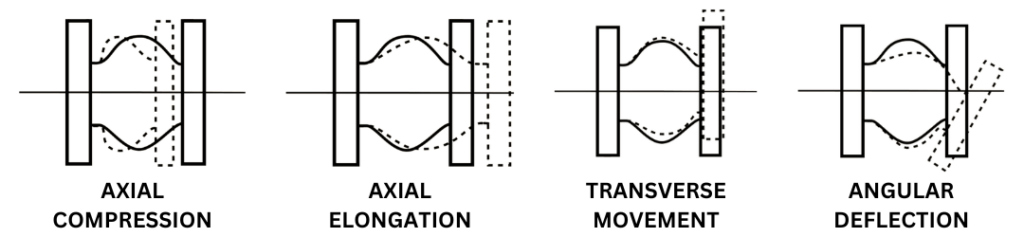

Rubber expansion joints are flexible connectors that absorb piping systems’ movements, vibrations, and misalignments. Within the rigorous landscape of mining, where resilience is paramount, these joints emerge as pivotal links, facilitating the smooth conveyance of materials, fluids, and gases while accommodating the structural shifts within mining systems.

Rubber expansion joints facilitate seamless operations while mitigating risks arising from movements, vibrations, and temperature variations. At API International, we recognize the unique demands of the mining industry, offering an array of top-notch rubber expansion joints tailored to your specific project requirements.

For all your rubber expansion joint requirements, navigate our diverse range of products at API International. Find tailored solutions compatible with your mining system demands. Contact us today and get connected with a dedicated account manager!

API International, Inc.

12505 SW Herman Road

Tualatin, OR 97062

API International, Inc. | All rights reserved. | Terms & Conditions | Privacy Policy