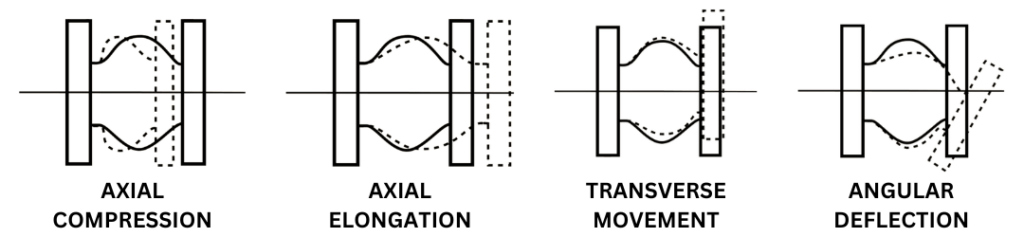

Rubber expansion joints, also known as flexible connectors, are designed to absorb movement, vibration, and noise in pipelines. Comprising layers of rubber and reinforcing materials, they accommodate movements caused by temperature variations, pressure fluctuations, and external forces. These joints extend pipeline lifespan and reduce maintenance costs, significantly benefiting the Water & Wastewater sector.

API International stands at the forefront, presenting an extensive array of rubber expansion joints tailored to fulfill diverse waterworks applications. From carbon steel and stainless steel single or twin sphere rubber expansion joints, to control rod units and braided pump connectors, API has you covered. We will explore the myriad of applications, uses, and technical intricacies of these steel flanges in the Waterworks industries.

Rubber expansion joints, also known as flexible connectors, are designed to absorb movement, vibration, and noise in pipelines. Comprising layers of rubber and reinforcing materials, they accommodate movements caused by temperature variations, pressure fluctuations, and external forces. These joints extend pipeline lifespan and reduce maintenance costs, significantly benefiting the Water & Wastewater sector.

As the backbone of effective and leak-resistant connections within the Waterworks industry, expansion joints underscore the industry’s performance, safety, and dependability imperatives. API International proudly offers a comprehensive assortment of rubber expansion joints catering to Waterworks system requisites, from conventional single-sphere & double-sphere expansion joints, to specialized counterparts like DIN Expansion Joints. With insights into these rubber expansion joints and accessories, applications, variations, proper maintenance, and technical aspects, industries can make informed decisions to elevate their exhaust systems’ longevity and operations.

For all your rubber expansion joint requirements, navigate our diverse range of products at API International. Find tailored solutions compatible with your clean water, wastewater, and waterworks demands. Contact us today and get connected with a dedicated account manager!

API International, Inc.

12505 SW Herman Road

Tualatin, OR 97062

API International, Inc. | All rights reserved. | Terms & Conditions | Privacy Policy