If you work in manufacturing, construction, or industrial sectors, you understand the need for reliable, high-quality components. Domestic flanges are crucial pieces that connect pipes, valves, and other equipment, ensuring efficient and secure fluid or gas flow. In this comprehensive guide, we’ll cover everything about domestic flanges, including their types, applications, industry standards, and the undeniable advantages they offer over imported alternatives, providing you with a sense of security in your operations.

Introduction to Domestic Flanges

Domestic or American-made flanges are manufactured within the United States, adhering to stringent quality standards and regulations. These flanges are designed to meet the demanding requirements of various industries, including oil and gas, chemical processing, power generation, and water treatment.

One key advantage of domestic flanges is their compliance with industry-recognized standards, such as ASME (American Society of Mechanical Engineers), AWWA (American Water Works Association), and MSS (Manufacturers Standardization Society). These standards ensure consistent quality, performance, and compatibility across different applications.

Types of Domestic Flanges

Domestic flanges are available in various materials, sizes, and pressure ratings to accommodate diverse industrial needs. Here are some of the most common types:

Stainless Steel Flanges: These flanges are renowned for their corrosion resistance and durability. They are ideal for harsh environments and demanding applications and are commonly used in the chemical processing, food and beverage, and pharmaceutical industries.

Carbon Steel Flanges: Offering superior strength and cost-effectiveness, carbon steel flanges are widely used in oil and gas pipelines, power plants, and general industrial settings.

Alloy Flanges: For extreme conditions involving high temperatures, pressures, or corrosive environments, alloy flanges from materials like Hastelloy, Inconel, or Monel provide exceptional performance and longevity.

Slip-On Flanges: These flanges are designed to be welded directly onto the pipe, providing a seamless and secure connection. They are commonly used in high-pressure and high-temperature applications.

Weld Neck Flanges: With a tapered hub for better stress distribution, weld neck flanges are preferred for high-pressure and high-temperature systems, ensuring enhanced safety and reliability.

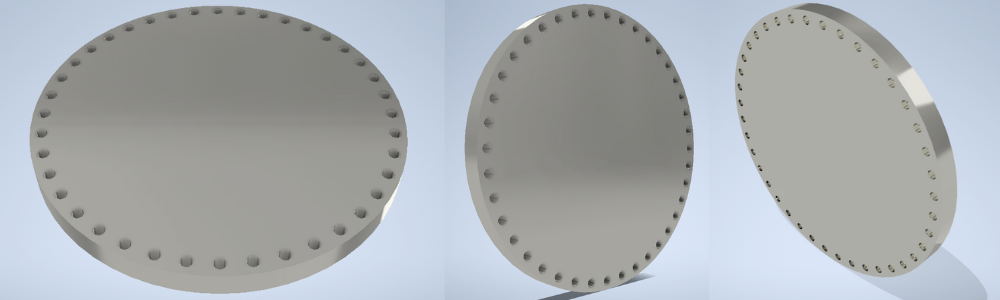

Blind Flanges: Also known as blanking flanges, these are used to seal off pipe openings or provide access points for maintenance and inspection purposes.

Applications of Domestic Flanges

Due to their versatility and reliable performance, domestic flanges find applications across various industries. Here are some typical applications:

Oil and Gas Industry: Flanges are essential in oil and gas exploration, production, and transportation, facilitating the secure and efficient flow of hydrocarbons.

Mining Industry: water transport and fluid handling within mining operations. Their robust connections stand firm against challenging conditions from dewatering to slurry transportation.

Power Generation Industry: Flanges are widely used in power plants, both conventional and renewable, to connect piping systems, valves, and other equipment.

Water and Wastewater Treatment: Domestic flanges play a vital role in water treatment facilities, helping to maintain the integrity of piping systems and ensuring the safe distribution of potable water.

Exhaust Industry: Flanges are key in joining exhaust system elements, providing leak-free connections, and optimizing exhaust flow.

Marine and Maritime Industry: It is common to follow DIN standards when selecting flanges for this industry. Stainless steel flanges are corrosion-resistant to withstand harsh maritime conditions.

Industry Standards and Certifications

Several industry standards and certifications manufacture domestic flanges to ensure quality, safety, and compatibility. Some of the most commonly followed standards include:

ASME B16.5: This standard covers flanges for piping systems, specifying dimensions, materials, pressure-temperature ratings, and marking requirements.

AWWA C207: This standard is specific to the water industry and covers flanged fittings for steel pipes, including flanges, gaskets, and bolting.

MSS SP-44: This standard provides guidelines for the proper selection, installation, operation, and maintenance of pipe fittings, including flanges.

NACE Certification: Flanges used in corrosive environments may require NACE (National Association of Corrosion Engineers) certification to ensure proper material selection and corrosion resistance.

Fire-Safe Certification: Fire-safe-certified flanges are essential for applications involving flammable or combustible materials. They mitigate the risk of fire and explosion.

Benefits of Choosing Domestic Flanges

While imported flanges may initially seem like a cost-effective option, there are numerous compelling reasons to choose domestic flanges for industrial applications. These include:

Quality Assurance: Domestic flanges are manufactured under strict quality control measures, ensuring consistent performance and reliability. They are subject to rigorous testing and inspections to meet industry standards.

Compliance with Regulations: By adhering to domestic standards and regulations, these flanges provide peace of mind, knowing they comply with all necessary safety and environmental requirements.

Shorter Lead Times: Domestic manufacturing facilities in the United States typically shorten lead times for domestic flanges, allowing for quicker turnaround and reduced downtime. API International has multiple warehouses stocked with various flanges for quick distribution across the United States

Technical Support and Customer Service: Domestic manufacturers often offer superior technical support and customer service, providing expert guidance and timely assistance.

Supporting Local Economies: Choosing domestic flanges contributes to the growth and sustainability of local manufacturing industries, creating jobs and strengthening the domestic supply chain.

Reduced Carbon Footprint: Domestic flanges can have a lower environmental impact than imported alternatives by minimizing transportation distances aligning with sustainability goals.

Selecting the Right Domestic Flange for Your Application

With many types and options available, selecting the appropriate domestic flange for your application can be daunting. Here are some key factors to consider:

Operating Conditions: Evaluate the temperature, pressure, and corrosive environments your piping system will be subjected to, as this will inform the material selection and pressure rating required.

Size and Dimensions: Ensure that the flange dimensions, bolt-hole patterns, and overall length are compatible with your existing piping system and equipment.

Industry Standards and Certifications: Verify that the domestic flange meets the relevant industry standards and certifications required for your application, such as ASME, AWWA, or NACE.

Gasket Compatibility: Different flange materials may require specific gasket materials to ensure a proper seal and prevent leakage or compatibility issues.

Installation and Maintenance Requirements: Consider the ease of installation, potential for future maintenance or replacement, and any special tools or equipment needed for working with the flanges.

Cost and Lead Time: While quality should be the primary consideration, factor in domestic flanges’ cost and lead time to align with your project timeline and budget.

API International’s machine shop enables us to manufacture custom flanges and other products that meet various specifications that utilize AIS, import, and exotic materials. We also support fast-turn modifications to our stock items to meet customer needs. Whether you have a CAD drawing or sample that needs reverse-engineered, we can work with you on prototyping, production quantity manufacturing, and even warehousing products.

Choose a Trusted Domestic Flange Manufacturer

Partnering with a reputable and experienced flange manufacturer is essential when sourcing domestic flanges. By partnering with reputable domestic flange manufacturers, you can ensure reliable supply, technical support, and peace of mind, knowing that your flanges meet the highest quality standards.

With over 45 years of experience in the flange industry, API International offers a comprehensive range of domestic flanges for various applications. It is backed by exceptional customer service and fast turnaround times.

Maintenance and Installation Best Practices

Proper installation and maintenance practices are essential to maximize the service life and performance of your domestic flanges. Here are some best practices to follow:

Flange Gasket Selection and Installation: Choose the appropriate gasket compatible with the flange material and operating conditions. Ensure proper gasket installation, following manufacturer guidelines for gasket compression and bolt tightening sequences.

Flange Bolt Tightening: Follow recommended bolt tightening procedures and torque specifications to prevent leakage, excessive stress, or damage to the flanges. Use calibrated torque wrenches and follow cross-pattern tightening sequences.

Flange Alignment: Ensure proper flange alignment during installation to prevent excessive stress on the piping system and avoid potential leaks or failures.

Handling and Storage: Carefully handle flanges to prevent damage and store them in a clean, dry environment protected from moisture, dust, and other contaminants.

Regular Inspections: Implement a regular inspection schedule to check for signs of wear, corrosion, or damage and address any issues promptly to prevent failures.

Flange Insulation: In high-temperature applications, consider using appropriate insulation materials to protect workers and maintain system efficiency.

Documentation and Record-keeping: Maintain detailed documentation and records of flange installations, maintenance activities, and any issues or repairs for future reference and traceability.

By following these best practices, you can ensure your domestic flanges’ safe and efficient operation, prolonging their service life and minimizing downtime and maintenance costs.

Our Technical Resources page covers various types of specifications and manuals!

If you have any questions, contact our team!

Future Trends and Innovations in Domestic Flanges

The domestic flange industry is continuously evolving, driven by advancements in materials science, manufacturing technologies, and industry demands for improved performance and efficiency. Here are some exciting trends and innovations shaping the future of domestic flanges:

Advanced Alloys and Materials: Researchers are exploring using advanced alloys and materials, such as nickel-based superalloys and ceramic matrix composites, to enhance the corrosion resistance, strength, and temperature capabilities of domestic flanges.

Smart Flanges: Integrating sensors and Internet of Things (IoT) technologies enables the development of “smart” flanges that can monitor and transmit data on temperature, pressure, and other operating conditions, enabling predictive maintenance and optimized system performance.

Improved Sealing Technologies: Manufacturers are continually refining gasket materials and sealing technologies to improve leak prevention and enhance the reliability of flange connections, particularly in high-pressure and harsh environments.

Sustainable Manufacturing: As environmental concerns become increasingly important, domestic flange manufacturers are exploring more sustainable production methods, incorporating eco-friendly materials and processes to reduce their carbon footprint and environmental impact.

These trends and innovations highlight the industry’s commitment to continuously improving domestic flanges, ensuring they meet the evolving demands of various industrial applications while prioritizing safety, efficiency, and environmental sustainability.

Conclusion

Domestic flanges are essential components in a wide range of industrial applications, playing a vital role in ensuring the safe and efficient flow of fluids and gases. By choosing domestic flanges, you can benefit from quality assurance, regulatory compliance, shorter lead times, exceptional customer service, and support for local economies.

With a deep understanding of the different types, applications, industry standards, and selection criteria, you can make informed decisions and choose the right domestic flange for your needs. Additionally, by partnering with reputable domestic flange manufacturers and following best practices for installation and maintenance, you can maximize the performance and service life of these critical components.

As the industry continues to evolve, embracing trends and innovations in materials, manufacturing processes, and intelligent technologies, domestic flanges will become even more reliable, efficient, and sustainable, further solidifying their importance in industrial applications. Investing in high-quality domestic flanges is investing in your operations’ safety, reliability, and long-term success.

Our sales team at API International can answer any questions regarding your project. We have multiple warehouses for quick distribution across the United States. Get connected with a dedicated Sales representative today!