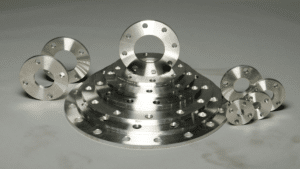

A grooved piping system is a durable, long-lasting option that can often be used in areas where flanged connections or welding aren’t possible or convenient. Explore the benefits of a grooved piping system and learn how grooved pipe fittings can make installation quicker, easier, and more cost-effective.

What Is a Grooved Piping System?

A grooved piping system uses a no-weld installation method that connects grooved pipes with a coupling. The result is a tight seal that’s suitable for a variety of applications, including water transmission and treatment and irrigation. Tees and elbows are added to change direction of flow, while caps and levers manage flow volume and create system endpoints.

How Does a Grooved Piping System Work?

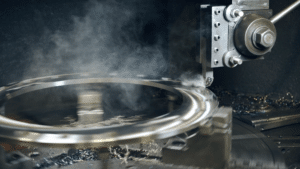

The pipes in a grooved piping system feature a groove that’s cut into the ends of each connecting pipe; these grooves may be either cold-formed or machined. To install the piping system, the grooved ends are aligned, a gasket is applied to the pipe end, then the coupling is secured around the gasket where it sits within the grooves. The coupling is secured with nuts and bolts to create a tight, leak-proof seal.

For directional or flow changes, elbows and tees are installed. Flow can be stopped and started with valves, and piping systems may be terminated with a cap. Grooved piping system components, such as nuts, bolts, and gaskets are likewise manufactured for performance across a range of applications, temperatures, and conditions.

Common Grooved Piping System Applications

While welded or flanged connections remain popular, there are some areas where these traditional pipe connection techniques won’t work or aren’t the best choice. Grooved piping systems offer an easier installation process over flanged types in a wide range of pipe sizes.

Grooved piping systems are available in rigid and flexible styles. KLAMPz lightweight flexible couplings reduce stress on a piping system caused by expansion, contraction, shock, vibration, and displacement or alignment changes due to natural circumstances. The options available at API International are ideal for applications where a limited amount of movement or shifting is expected. This is similar to how expansion joints reduce vibration and allow for movement.

Grooved Piping System Benefits

KLAMPz grooved pipe fittings and couplings made with ductile iron are strong and long-lasting, and piping components such as steel adapter nipples also offer strength and durability. A flexible coupling and gasket combination dampens vibrations, which reduces damage to piping system connections and joints for fewer required repairs. But, the advantages of grooved piping systems extend beyond reliability.

Installation Speed

Quicker installation of grooved piping systems means you’re able to meet deadlines and prevent backed-up projects and staff shortages. Because welding is not necessary, welder’s may turn their attention elsewhere for a speedier installation, overall. Visual inspection confirms installation faster, too: If the joint meets metal-to-metal, you have a proper seal. This process improves installation speed and makes future maintenance easier as well. Reduced installation and repair time and less need for welding or other special labor mean overall total cost is reduced.

Safety

Reduces some of the risks associated with other approaches to making connections in a piping system. No welding means the installation process doesn’t require hot work, flames, or sparks, which reduces fire risk. UL-listed and FM-approved components offer reliable, long-lasting use in tough conditions and inclement weather. ASTM International, American Water Works Association (AWWA), and American National Standards Institute (ANSI) rated parts meet the standards for materials, strength, and reliability for a range of applications.

Adaptability

This versatile grooved design provides benefits from initial installation to repair and system expansion. Precision installation, with no bolt holes to line up, reduces alignment issues that may occur when installing flanged piping systems. When the pipes are abutted and the gasket is applied, the coupling installs easily, without concern for orientation. For even more versatility, a flange adapter allows the transition between a flanged connection and grooved joint and pairs with a variety of fittings and accessories.

Updating and Expanding

When updating or adding to a piping system, grooved components can be easily dismantled or expanded. Expanding a grooved piping system is easier and faster as the couplings unlock quicker than a bolted flange connection. Not only does a faster expansion reduce working time, it means less downtime for the piping system as a whole. Accessing the system is as simple as removing the bolts, coupling, and gasket—which provides access to clean, repair, or expand the piping system. Welded flange systems take significantly longer to dismantle or access than a grooved piping system.

Grooved piping systems are easy to install and maintain, and they are suitable for a variety of applications. Contact us for more information, to request custom solutions, or to find the piping system components that meet your specifications.