The real issue behind most mismatches

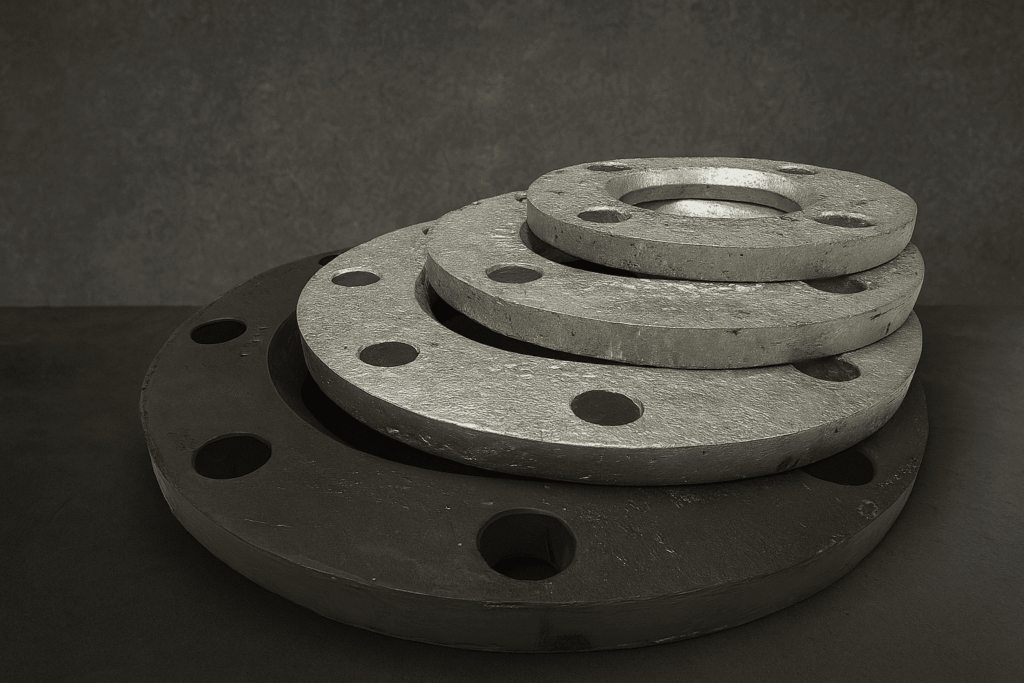

Most flange mismatches happen because people assume all flanges are the same. In reality, flanges from different manufacturers can vary in size, pressure rating, material, and bolt hole pattern.

To avoid these problems, always double-check the basics before buying or installing a flange. Look at the size, pressure rating, material, bolt pattern, and the standard it follows. Review the manufacturer’s documents and compare key measurements. Catching mistakes early can save you hours or even days during installation or repair.

A flange connects two pipes and keeps whatever is inside from leaking out. A gasket goes between the flanges, and tightening the bolts squeezes the gasket to create a seal.

Problems begin when the two flanges are not made to the same specification.

What standards actually solve

If every manufacturer made flanges differently, mismatched bolt patterns and alignment problems would happen all the time.

Standards help prevent these problems. They set rules for size, drilling patterns, pressure ratings, and tolerances that all manufacturers must follow. For example, think water (AWWA), power (ASME), and oil and gas (API) as a simple mental map to instantly place each standard in the right context. AWWA standards are used in water and utility systems, ASME standards are common in industrial and power plants, and API standards are used in oil and gas.

To make sure a flange meets the right standard, manufacturers provide documents like mill test reports and certificates of conformance. The goal is simple: flanges from different companies should fit and bolt together without any changes.

Standards make flanges predictable, which allows systems to be repaired or replaced without custom work.

A quick way to look at mismatches vs. standards

| Without Standards | With Standards |

|---|---|

| One shop makes a flange one way, another makes it differently | Everyone follows the same specification |

| Replacement flanges don’t match existing equipment | Flanges from different sources are compatible |

| Bolt holes and patterns vary | Repeatable dimensions and drilling |

| Parts don’t bolt together | Connections line up as expected |

What a flange means in practice, not just on paper

A flange is more than just a ring with bolt holes.

At a practical level, it functions like a lip—something you can push against, pull on, and secure. When that idea is applied to piping, the result is a ring attached to the end of a pipe. Bolt holes are added so the two ends can be pulled together and held in place.

This simple idea is the basis for the standardized flanges used in many industries today.

Why standardization matters for repair and replacement

Many systems are built in sections so you can repair or replace parts without taking everything apart.

This design approach allows you to remove, replace, and reinstall a damaged section. While having more joints can cost more at first, it also means less downtime. You only need to fix the damaged part, not the whole system. Connection points follow established specifications. Matching flanges means faster repairs, fewer surprises in the field, and less time spent making parts fit. Over the long run, that reliability often matters more than saving a little upfront.

Standardization also makes it easier to keep parts in stock. When parts follow the same specs, you can grab replacements from inventory and install them without extra adjustments.

A simple repair example

Suppose a 20-foot section of pipe is damaged. Instead of replacing the whole length, you just remove the damaged part.

Now there’s a gap.

Lining up and welding new pipe is hard and risky. A better approach is to install flanges at both ends, verify that everything meets the specs, and close the gap with bolts.

In the field, technicians don’t have to guess. They rely on the sizes, patterns, and tolerances set by standards.

Standards save hours and headaches

Most flange mismatches happen because the two sides were made to different standards.

Specifications prevent this by giving everyone a common reference. This consistency means faster repairs, easier stocking, and fewer surprises during installation. In short, standards help you avoid showing up at a job site and finding out your flange doesn’t fit the one already there.

API International flange experts

Finish your job faster, avoid surprises, and be confident that your flanges will fit the first time. Whether you want to cut installation time, simplify repairs, or eliminate costly mismatches, our flange team helps you make it happen. Browse our online catalog or call 503.692.3800, and get straight answers to your specification or compatibility questions. Let us help you complete your project on schedule and with peace of mind.