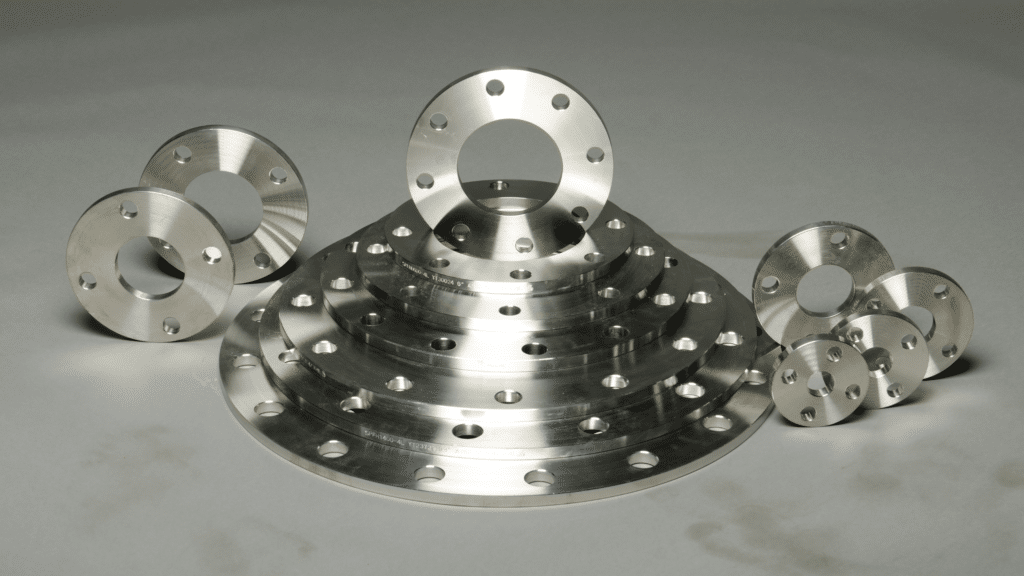

Flanges are crucial in piping systems, acting as connectors that join pipes, valves, pumps, and other equipment. Among the various standards for flanges, those specified by the American Water Works Association (AWWA) and the American National Standards Institute (ANSI) are prominent. This blog will investigate AWWA C207 and C228 flanges, examining their characteristics, applications, and differences from ANSI flanges.

AWWA C207 Flanges

AWWA C207 is a standard for steel ring flanges for waterworks service, providing guidelines for the design, materials, dimensions, and testing of flanges used in water systems. The C207 standard includes several classes of flanges, each designed to handle different pressure ratings. The main pressure classes are:

- AWWA Class A Flange: Rated for 50 psi (3.5 bar) working pressure.

- AWWA Class B Flange: Rated for 86 psi (6 bar) working pressure.

- AWWA Class D Flange: Rated for 175 psi (12 bar) working pressure.

- AWWA Class E Flange: Rated for 275 psi (19 bar) working pressure.

- AWWA Class F Flange: Rated for 300 psi (21 bar) working pressure.

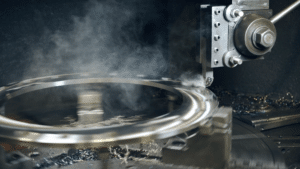

These flanges are typically made from carbon steel and are designed to handle the lower pressure requirements of waterworks systems compared to industrial applications. They are commonly used in pipelines, water treatment plants, and other infrastructure projects.

Example Specification for AWWA C207 Class D Flange:

- Material: Carbon steel conforming to ASTM A36 or equivalent.

- Dimensions: The flange thickness and bolt circle diameters vary according to pipe size, following specific tables in the standard.

- Pressure Rating: 175 psi.

- Design: Ring-type flange suitable for slip-on or weld-neck connection.

AWWA C228 Flanges

AWWA C228 is a newer standard that specifies stainless-steel pipe flanges for water service. It includes guidelines for the design, material, dimensions, and testing of stainless-steel flanges used in potable and non-potable water systems. Stainless steel offers enhanced corrosion resistance, making C228 flanges suitable for environments where water quality and longevity are critical.

Example Specification for AWWA C228 Flange:

- Material: Stainless steel, typically grades such as 304 or 316.

- Dimensions: Conforms to the same dimensional criteria as the C207 standard, ensuring compatibility with existing systems.

- Pressure Rating: Various classes are defined in the standard, similar to C207.

- Design: These can be slip-on, weld-neck, or blind types, depending on application requirements.

The Difference Between ANSI and AWWA Flanges

While AWWA flanges (both C207 and C228) are specifically designed for waterworks applications, ANSI flanges cater to a broader range of industries, including oil and gas, chemical, and power generation. Here are some key differences:

- Pressure Ratings:

- ANSI Flanges: Designed to handle higher pressure ratings. ANSI B16.5, for example, includes classes ranging from 150 psi to 2500 psi.

- AWWA Flanges: Generally rated for lower pressures, suitable for waterworks, with ratings typically not exceeding 300 psi.

- Material:

- ANSI Flanges: Available in various materials, including carbon steel, stainless steel, alloy steel, and more, to suit different industrial needs.

- AWWA Flanges: Typically made from carbon steel (C207) or stainless steel (C228), optimized for waterworks service.

- Dimensions:

- ANSI Flanges: Follow the dimensional standards set forth by ASME/ANSI B16.5, which specifies the dimensions for pipe flanges and flanged fittings in sizes from 1/2 inch to 24 inches.

- AWWA Flanges: Dimensional standards are specific to waterworks’ needs, with sizes ranging from 4 inches to 144 inches, as specified in AWWA C207 and C228.

- Applications:

- ANSI Flanges: Used in various high-pressure and high-temperature industrial applications.

- AWWA Flanges: Primarily used in water supply and treatment systems, where the pressure requirements are generally lower.

Practical Examples Of AWWA and ANSI Applications

Example 1:

Water Treatment Plants

A water treatment plant requires flanges to connect various pipes and valves. The choice between AWWA C207 and ANSI B16.5 flanges depends on the specific requirements:

- AWWA C207 Class D Flanges: Suitable for most connections due to their adequate pressure rating (175 psi) and cost-effectiveness for large-diameter pipes.

- ANSI B16.5 Class 150 Flanges: Might be chosen for specific high-pressure sections or where equipment compatibility is necessary.

Example 2:

Industrial Cooling Systems

An industrial cooling system using treated water may need flanges for its piping network:

- ANSI B16.5 Class 300 Flanges: These are likely to be used due to the higher pressure and temperature conditions.

- AWWA C228 Stainless Steel Flanges: This could be chosen for sections where corrosion resistance is critical, especially if the water has high salinity or other corrosive properties.

Understanding the differences between AWWA C207, C228, and ANSI flanges is crucial for selecting the right components for your project. AWWA flanges, with their lower pressure ratings and specific design for waterworks, provide cost-effective and reliable solutions for water treatment and distribution systems. In contrast, ANSI flanges offer higher pressure ratings and material versatility, making them suitable for a broader range of industrial applications.

When specifying flanges for your project, consider the application’s pressure requirements, material compatibility, and dimensional needs to ensure optimal performance and longevity of the piping system. Whether working on a municipal water supply project or an industrial facility, choosing the appropriate flange standard is critical to achieving efficient and reliable connections.

Our sales team at API can answer any questions about your flange requirements. Depending on its application, they can also recommend alternative products that may be better suited for your system.

Get connected with a dedicated sales representative today!