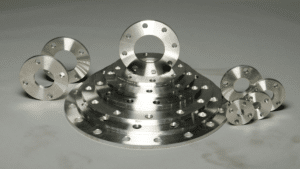

When purchasing flanges, you must consider the flange material in addition to physical measurements and bolt hole alignment. The chemical composition and physical properties are important in determining whether a material will be appropriate for a given application. You can look to a combination of standards to guide your decision.

What are the different types of flange materials?

Pipes and flanges must be durable enough to withstand heat, pressure, vibrations, and corrosion, while still providing a leak proof seal. Flange class helps determine bolt hole alignment, pressure and temperature rating, and dimensional standards, however, flange material specifications must also be considered based on your application:

- Steel is the most common flange material and has higher carbon content for applications requiring superior strength

- Stainless Steel is used when high durability and corrosion resistance is required

- Aluminum flanges are used for applications where corrosion resistance is important, and a light weight material is required like in irrigation

- Ductile Ironoffers a higher yield strength and is lower cost than steel, so preferred for instances where the flange doesn’t come in contact with the medium (like with backing flanges) and cost is an important consideration

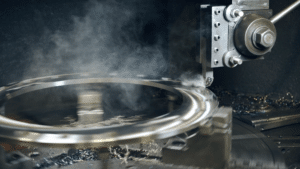

The manufacturing method is also important to understand. There are typically three methods used:

- Plate flanges are manufactured when metal slabs are sent through rollers until they reach the desired thickness. A plate flange typically costs less, but doesn’t offer the same strength or variety of material and sizes that other manufacturing methods do.

- Cast flanges are manufactured by pouring molten metal into a flange mold. The metal cools and hardens, and then the flange is removed from the mold and machined to the appropriate specifications. This lower-cost option offers plenty of flexibility, but does not produce the highest strength flanges.

- Forged flanges are made through a process of heating and forming the material, and then machining the part to the proper specifications. This creates the highest strength flange, but comes at a higher cost.

Consider the Intended Application

Choose the right flange material based on its intended use and the requirements specific to that application. Generally, your flange material will match your pipe material, but this is not always the case. Consider the strengths and weaknesses of each material when designing a piping system; the material should suit the application requirements or it may fail prematurely.

Pipe material is chosen based on variables associated with an application, including:

- What flows through the pipes (fluids, air, etc.)

- Expected high or low temperature

- Pressure conditions

- Maintenance requirements

- Environment

- Budget considerations

Certain fluids, for example, fuel or corrosive liquids, require pipes and flanges manufactured of stainless steel, alloy, or other corrosion resistant materials. Pipes and flanges used for air or other non-corrosive applications may not require the same corrosion resistant material as acidic or caustic liquids.

Consult Flange Requirements and Standards

The standards dictate the chemical composition, dimensions, and other specifications for flanges. Generally, your flange and pipe material should meet the same standards.

American Society for Testing and Materials (ASTM) standards—displayed as the “grade” of the material used to manufacture the flange—is determined by the metal’s chemical composition. More specifically, this standard dictates how much carbon and other chemical elements are allowed to make up the raw material.

- ASTM A36 is a low-carbon steel favored for its welding properties and is suitable for machining, making it a common material for steel flanges.

- ASTM A105 is the standard for carbon steel piping components, particularly for high-temperature applications.

- ASTM A182 is the standard for alloy and stainless steel piping flanges and fittings. Alloy steel flanges are produced with more chrome and molybdenum, so they are sometimes preferred for corrosion resistance and can better withstand high temperatures and high pressure.

- ASTM A240 is stainless steel plate that offers strength at high temperatures, and high corrosion resistance. While ASTM A182 and ASTM A240 have similar chemical properties, the production method differs: A240 is plate; A182 is forged, which may affect materials choice.

- ASTM A536 covers ductile iron, which is used for backing flanges.

Guobiao (GB) standards are issued by the Standardization Administration of China (SAC) and include:

- Q235B is a low-carbon steel manufactured in China. The structure allows adequate welding and bolt connection. This steel exceeds AWWA strength requirements and is considered the China comparable material to DIN EN S235JR and ASTM A36 standards (but with slightly lower strengths).

American Water Works Association (AWWA) standards include specifications for steel and stainless steel. AWWA flanges include:

- AWWA C207 is the specification for steel ring or slip-on flanges and blind flanges

- AWWA C228 is the specification for stainless steel and may use 304L or 316L stainless steel. 304L contains more chromium and less nickel than 316L. The 316L material also includes molybdenum for improved corrosion resistance.

American National Standards Institute (ANSI) and American Society of Mechanical Engineers (ASME) are the industry standards for pipeline flanges in the United States. These standards include B16.1, B16.5, and B16.47 and cover steel, forged, or cast flanges.

Deutsches Institut für Normung (DIN, German Institute of Standardization) is an international standard that applies to steel and stainless steel metric flanges and commonly in maritime applications.

Flange Material Source

It is also important to consider the requirements around where the flange material is sourced from. For many applications it may be fine to us import material in order to save on cost, but often Buy America or Domestic material may be required.

The Buy America standard was developed for government funded transportation projects to provide preference to domestically produced materials, but there are provisions that allow for materials to be sourced from a list of approved countries if it is a small enough part of the total contract, and domestic product availability is low or price is too high.

Our Domestic flanges meet the American Iron & Steel (AIS) standard, which allows imported raw components of the metal, but requires that the flange material be melted and manufactured in the United States.

Domestic flanges are able to be substituted in Buy America applications, and Buy America flanges can be substituted for applications where Import flanges are acceptable, but they can’t be substituted in the other direction.

Other Factors for Choosing Flanges

Consider the pipe material, pressure and temperature ratings, flange dimensions, and tolerances, to determine the appropriate flange material. ANSI ratings provide information on pressure and heat tolerances.

Fitting type is an important consideration as well. Does your fitting require welding? If so, the material you use should allow welding. For non-welded styles, such as lap joint or threaded flanges, weldability is less of a concern, and other requirements will take precedence.

When choosing the ideal flange material, refer to the standards required for your intended application, consider the pipe material that will connect to the flange, and ensure the flange material you choose is rated for the temperature and pressure it must withstand. Or, contact API International, Inc. for assistance with standard fittings or custom machined parts or for further information.