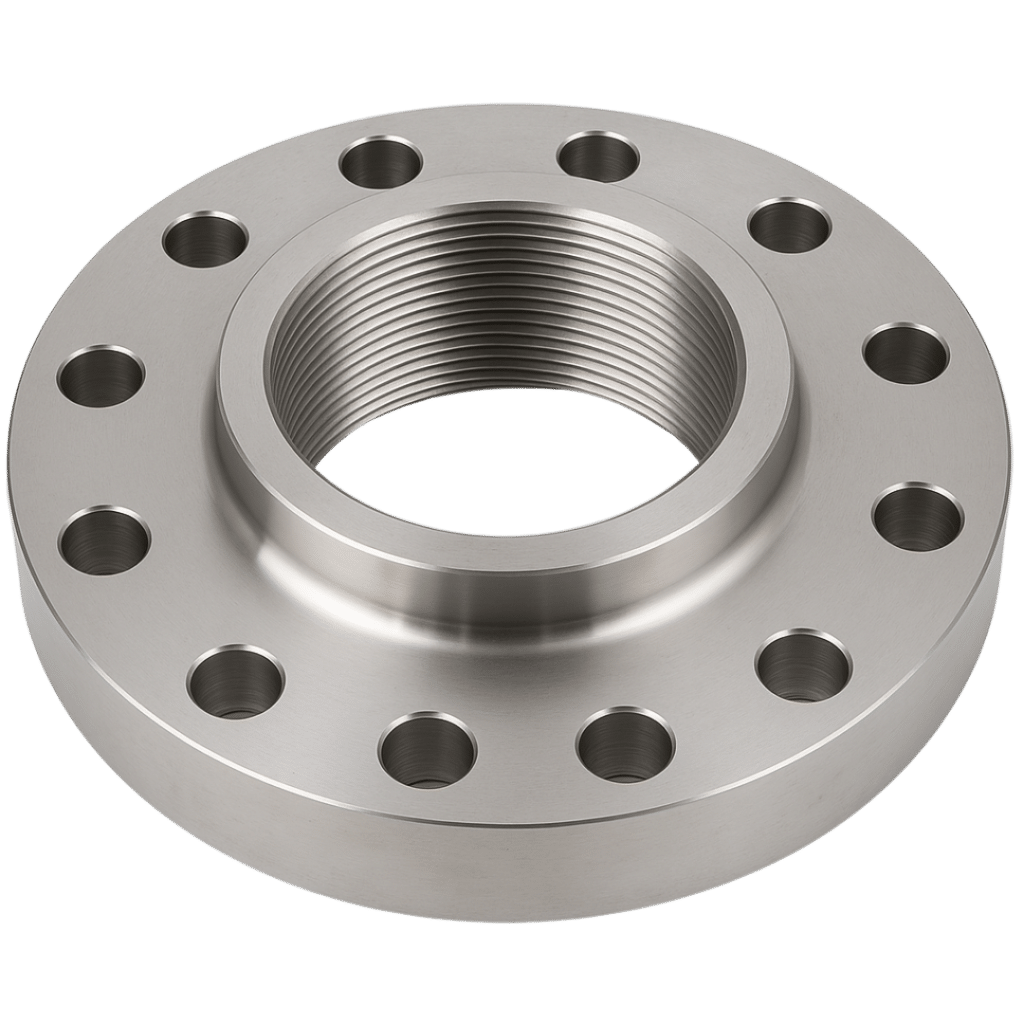

We stock steel and stainless steel ASME flanges in slip-on and blind styles, available in both flat face and raised face designs, offered in class 150 and 300.

The American Society of Mechanical Engineers (ASME) is one of the oldest and most respected standards-developing organizations in the United States. Founded in 1880, ASME supports mechanical engineering innovation through technical standards, training, research, and certification.

ASME develops around 600 codes and standards that guide the design, manufacturing, and inspection of critical mechanical systems—including fasteners, elevators, plumbing fixtures, pipelines, boilers, and pressure vessels. These standards are created through a transparent, consensus-driven process by subject matter experts and are widely adopted by industries and governments across the globe.

ASME also provides clear standards that shape how flanges are designed, built, and used across industrial systems, helping ensure reliability and compatibility in real-world applications.

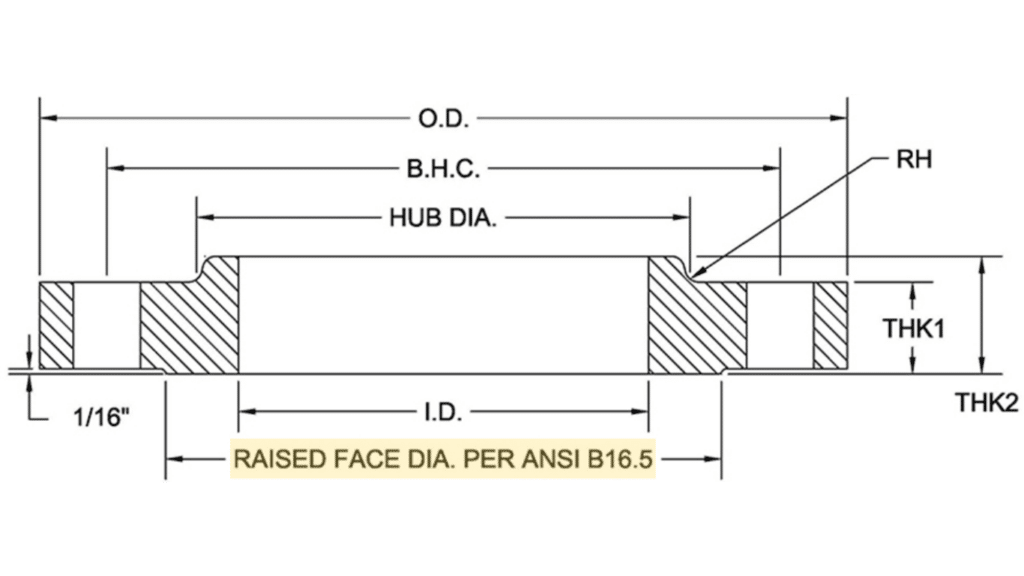

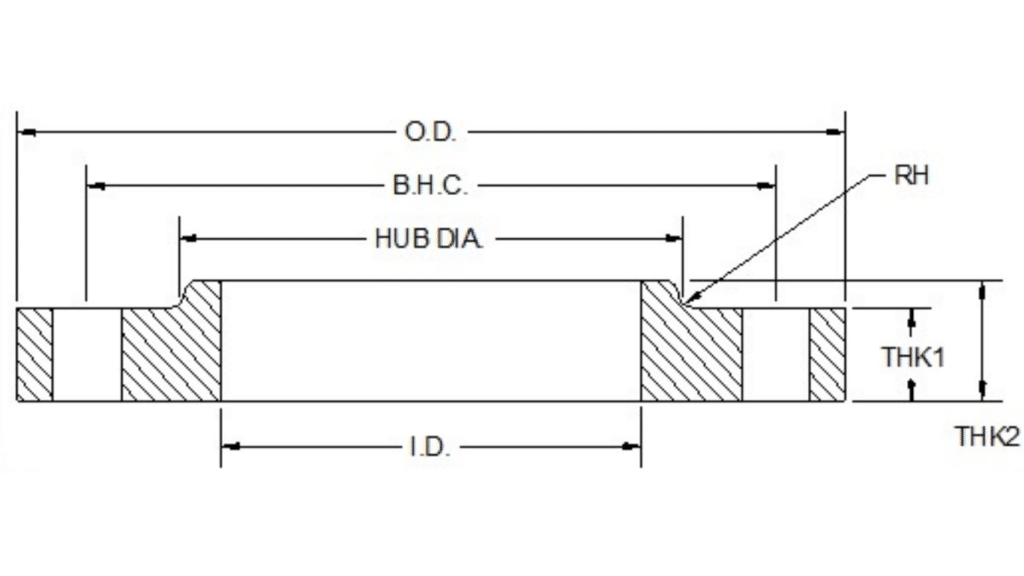

ASME B16.5 and B16.47 are the most common standards for ASME flanges. They define flange dimensions, pressure classes, materials, and tolerances.

ASME B16.5 flanges are specifically designed for pipe sizes ranging from ½” to 24″. They are available in pressure classes 150, 300, 400, 600, 900, 1500, and 2500. Common materials include ASTM A105 carbon steel, 304L, and 316L stainless steel.

B16.5 covers Threaded, Slip-on, Lapped, Blind, and Weld Neck flanges.

ASME B16.47 flanges cover larger-diameter pipe systems, 26″ through 60″, with pressure classes such as 75, 150, 300, 400, 600, and 900. They are commonly used in high-volume and high-pressure systems. ASME B16.47 is further divided into Series A (covering blind flanges) and Series B (covering weld neck flanges).

Slip-ons, threaded, and socket weld are not covered by the ASME B16.47 standard and are instead manufactured to industry (non-ASME) standards. These “industry standard” designs are based on B16.47 bolt patterns and hub geometry, but dimensions vary by manufacturer. Always confirm details before fabrication.

Fits over the pipe and is welded in place. Commonly used in low- to moderate-pressure systems.

The ASME standard for flanges is ASME B16.5, which specifies dimensions, pressure classes, materials, tolerances, and testing for pipe flanges and fittings from ½ inch to 24 inches. For sizes above 24 inches, ASME B16.47 applies and is divided into Series A and Series B for different design needs.

ANSI approves standards, while ASME develops them. “ANSI flanges” actually follow ASME B16.5 standards for dimensions and pressure ratings. ASME B16.5 covers NPS ½” to 24” in pressure classes 150 to 2500. Sizes 26″ to 60″ are covered under ASME B16.47 in pressure classes 75, 150, 300, 400, 600, and 900. B16.5 covers Threaded, Slip-on, Lapped, Blind, and Weld Neck flanges.

ASME B16.5 is the actual standard produced by the ASME, however “ANSI” is frequently used to refer to the class ratings within that standard, which define pressure-temperature ratings for flange. Essentially, ASME B16.5 establishes the requirements, and ANSI class ratings are part of that document and show the flanges’ pressure capacities.

ASME B16.5 includes seven standard pressure classes: 150, 300, 400, 600, 900, 1500, and 2500. These ratings define the maximum allowable pressure a flange can withstand, depending on material type, temperature, and application.

ASME B16.5 is used in industries such as oil and gas, chemical processing, power generation, and water treatment where flanged piping systems are required.

ASTM standards focus on the material specifications for flanges. Common examples include ASTM A105 for carbon steel flanges and ASTM A182 for forged stainless and alloy steel flanges. These standards ensure the material properties meet the mechanical and thermal requirements of their applications.

• Custom Bolt Holes, Overbore, Counterbore, Tapped, Welds, O-ring Grooves, Threads, Special Serrations, Bevels, Chamfers

• Metric Parallel, Metric Tapered, Parallel (BSPP), Taper Thread (BSPT), UN/UNF/UNC Thread, NPT (National Pipe Thread)

• MWD

• Contact API’s engineering department for exact specifications and tolerances.

Plastic: Delrin, POM, Lexan, Nylon 66, Nylon 6, PEEK, PP, PE, Acetal

Rubber: EPDM, Neoprene, Buna-N, Viton

Aluminum: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

Copper: 3600, 3604, 3771

Titanium: 1-28

Steel Series:

• Ductile Iron: ASTM A536

• Carbon/Mild Steel: A105, A36, A516-70, A572-50, etc.

• Stainless Steel:

- 300 Series – 303, 304, 304L, 316, 316L

- 400 Series – 420J2, 430, 434, 442

Special Metals: Hastelloy, Inconel, Incoloy, Duplex 2205, Super Duplex 2507, Chrome Steel, alloys, or their equivalents

Stock Finish, Spiral Serrated (Phonographic), Concentric Serrated, Smooth Finish, Cold Water Finish, MWD, Phonographic

Dipped, Nickel Plating, Zinc Plating (clear, yellow, black, red, blue), Super Agitine, Powder, Painted, Galvanized, Epoxy, Lacquer

Water/Wastewater, Irrigation, Agriculture, HVAC, Marine, Exhaust, Mining, Energy/Power Generation/Oil

• Forged:

- Ring Rolling:

• Materials: Carbon Steel, Stainless Steel, Duplex

• Size: 2–202”

• Cast:

- Centrifugal Casting (Industrial):

• Material: Stainless Steel

- Continuous Casting:

• Material: Stainless Steel

- Sand Casting:

• Material: A536, Stainless Steel, Ductile Iron

- Investment/Lost-Wax/Precision Casting

• Material: Stainless Steel

Machining: Milling, Turning, Facing, Boring, Drilling, Tapping, Counter Sinking, Laser Cutting, Water Jet, Plasma Cutting

| Products | Type | Materials | Size Range |

|---|---|---|---|

| Flanges | Flat-Face, Raised-Face, & Plate: Slip-On/Ring Weld, Neck, Blind, Socket Weld, Orifice, Reducing, Threaded | See Materials List | 5–202″ |

| Gaskets | Molded, Extruded, sheet | EPDM, Buna-N, NBR, Non-Asbestos (GNA), Red Rubber (GRR), Viton | 5–60″ |

| Screens For Filters | Basket Screens and Cone Screens (Perforated, Mesh) | Galv. Carbon Steel, Carbon Steel, Stainless Steel | 6”D x 8’-H |

| Rings | Exhaust Rings (Marmon Flanges for DPF Filters) | Carbon Steel, Stainless Steel, Aluminum | 1–16” |

| Seamless Rolled Rings | Forged | Carbon Steel, Stainless Steel, Aluminum | 1–165” |

| Square Hole Rings | Repair Couplers | Carbon Steel, Stainless Steel, Galvanized, Epoxy Coated | 3–32” |

| Fabricated Assemblies | Weldments, Pipe Spools, Valve Bodies, Silencer Housings | Carbon Steel, Stainless Steel | 2–24” |

| Long/Short Radius Elbows | EN 10253-2–S235, P235GH–P265GH–P265NL and ASTM A234, WPB, WPC/ A420 WPL6, WPL3/ A860 WPHY52/ ASTM A234 WP11, WP22, WP5, WP9–16Mo3 | 304L & 316L Stainless Steel | (45° & 90°): OD: 21.3mm (1/2”)–3048mm (120”) WT: Up to SCH. XXS/160 |

| Miscellaneous | Tubesheets / Diffuser Plates / Baffles / Ferrules / Sleeves / Pins | Carbon Steel, Stainless Steel, Duplex | 5–104” |

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews