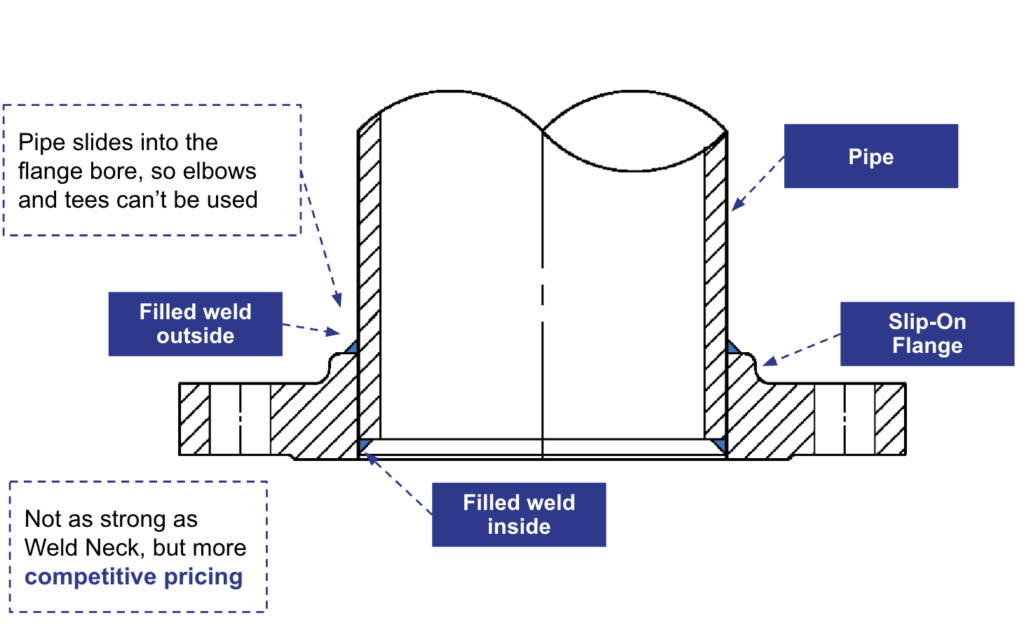

Slip-On Flanges

Slip-on flanges are designed to slide over the outside diameter of a pipe until the pipe end is flush with or slightly beyond the flange face. The flange is then permanently joined to the pipe with both an inner and outer fillet weld.

Features:

Standards: Defined under ASME B16.5 (sizes NPS ½”–24″), ASME B16.47 (NPS 26″–60″), and AWWA C207/C228 for waterworks.

Pressure Ratings: Available in Classes 150 through 2500 (depending on size).

Materials: Commonly produced in carbon steel, stainless steel, and alloy steels.

Facings: Raised Face (RF) and Flat Face (FF) are standard.

Applications: Commonly used in waterworks, low and medium pressure piping, cooling water lines.

Advantages: Easy to install, cost-effective, requires less pipe preparation compared to weld-neck flanges.

Limitations: Lower fatigue resistance than weld-neck flanges; not recommended for severe cyclic service or critical process applications.

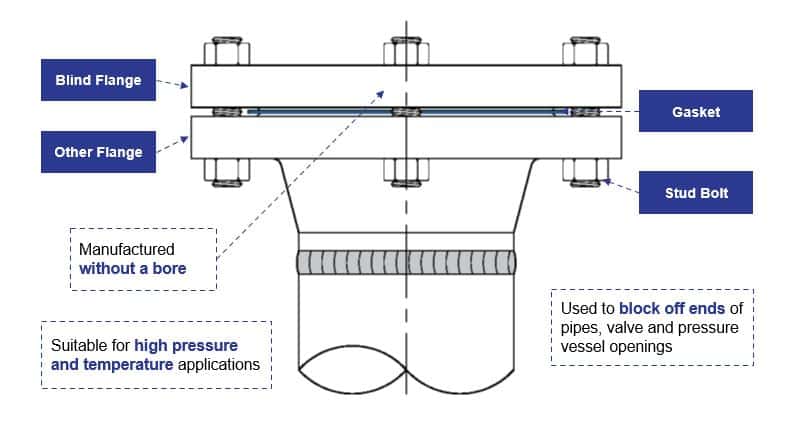

Blind Flanges

Blind flanges are solid disks used to seal the end of a piping system or pressure vessel, as they lack a bore. They are easily bolted onto a mating flange and can be quickly removed for system inspection, pressure testing, or future expansion.

Features:

Standards: Covered by ASME B16.5 (NPS ½”–24″) and ASME B16.47 (NPS 26″–60″), plus AWWA C207/C228 for water service.

Pressure Classes: From Class 150 up to Class 2500 (ASME B16.5) and 75–900 (ASME B16.47).

Facings: Raised Face (RF), Flat Face (FF), and sometimes Ring-Type Joint (RTJ) for high-pressure services.

Materials: Manufactured in the same range as slip-on flanges, from carbon steel to exotic alloys.

Applications: Ideal for hydrostatic testing, isolating sections of pipe, or sealing off unused nozzles.

Advantages: Strong and reliable for blocking flow; versatile across all pressure classes and diameters.

Limitations: Can be heavy at larger diameters; bolting torque requirements increase significantly with size and class.

Detailed Comparison Table: Slip-On vs Blind Flanges

| Aspect / Feature | Slip-On Flange (SO) | Blind Flange (BL) |

|---|---|---|

| Definition | A flange that slips over the pipe OD and is welded with two fillet welds (inside & outside). | A solid disk without a bore, used to seal off the end of a piping system or pressure vessel. |

| Primary Function | Connects piping or equipment while allowing flow. | Terminates a line, nozzle, or vessel and prevents flow. |

| Attachment Method | Requires welding: fillet welds at the pipe ID and OD. | Bolted connection only; no welding required. |

| Standards | Covered by ASME B16.5 (NPS ½–24) and B16.47 (NPS 26–60), AWWA C207/C228. | ASME B16.5 (½–24), ASME B16.47 (26–60), AWWA C207/C228. |

| Pressure Rating | Pressure class rating per ASME B16.5 (up to 24″): Class 150 – Class 2500. | Pressure class rating per ASME B16.5 (up to 24″): Class 150 – Class 2500; ASME B16.47 (>24″): Class 75 – Class 900. |

| Facings | Raised Face (RF), Flat Face (FF). | Raised Face (RF), Flat Face (FF), Ring-Type Joint (RTJ) for higher pressure. |

| Gasket Compatibility | Spiral-wound, RTJ, or others depending on facing. | Same gasket standards; bolting must be carefully managed, especially in large sizes. |

| Materials | Forged carbon steel (ASTM A105), stainless/alloy (ASTM A182), low-temp (ASTM A350). | Same materials apply. |

| Installation | Easy alignment; minimal prep; requires welding. | Simple bolted connection; no welding needed. |

| Strength & Durability | Adequate for low to medium pressure service; less robust under cyclic loads than weld-neck. | Strong and durable as a closure; design ensures safe pressure sealing. |

| Maintenance | Removal requires cutting welds; not reusable once detached (unless re-machined). | Easily removed, re-gasketed, and reused if undamaged. |

| Applications | Waterworks, general service, low to moderate pressure piping. | Hydrotests, isolation, dead-ends, future tie-ins, vessel nozzles. |

| Cost | Generally cheaper to purchase and install. | Cost varies; heavier is more expensive, especially in large diameters. |

| Weight | Lighter, less material compared to blind. | Can be very heavy in large sizes. |

| Service Restrictions | Limited in high risk, cyclic, or cryogenic service. | None beyond standard pressure/temperature limits. |

| Flexibility | Useful in systems where frequent flange alignment issues occur. | Provides future flexibility for system modifications. |