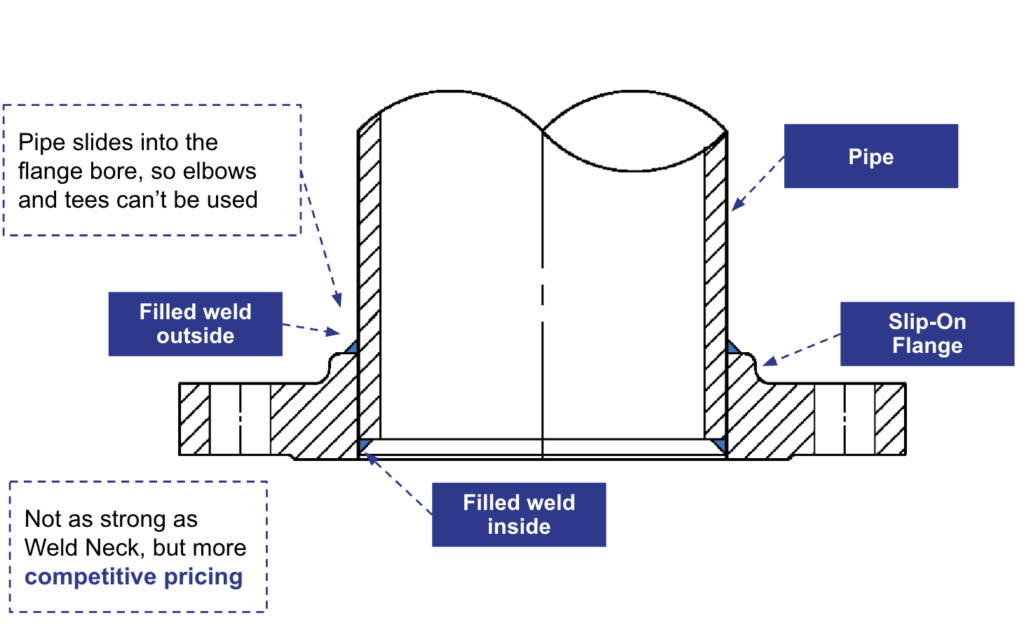

Overview of Slip-On Flanges

Slip-on flanges are designed to slide over the outside diameter of a pipe until the pipe end is flush with or slightly beyond the flange face. The flange is then permanently joined to the pipe with both an inner and outer fillet weld.

Features:

Standards: Defined under ASME B16.5 (sizes NPS ½”–24″), ASME B16.47 (NPS 26″–60″), and AWWA C207/C228 for waterworks.

Pressure Ratings: Available in Classes 150 through 2500 (depending on size).

Materials: Commonly produced in carbon steel (A105), stainless steel (ASTM 182), and alloy steels.

Facings: Raised Face (RF) and Flat Face (FF) are standard.

Applications: Commonly used in waterworks, low and medium pressure piping, cooling water lines.

Advantages: Easy to install, cost-effective, requires less pipe preparation compared to weld-neck flanges.

Limitations: Lower fatigue resistance than weld-neck flanges; not recommended for severe cyclic service or critical process applications.

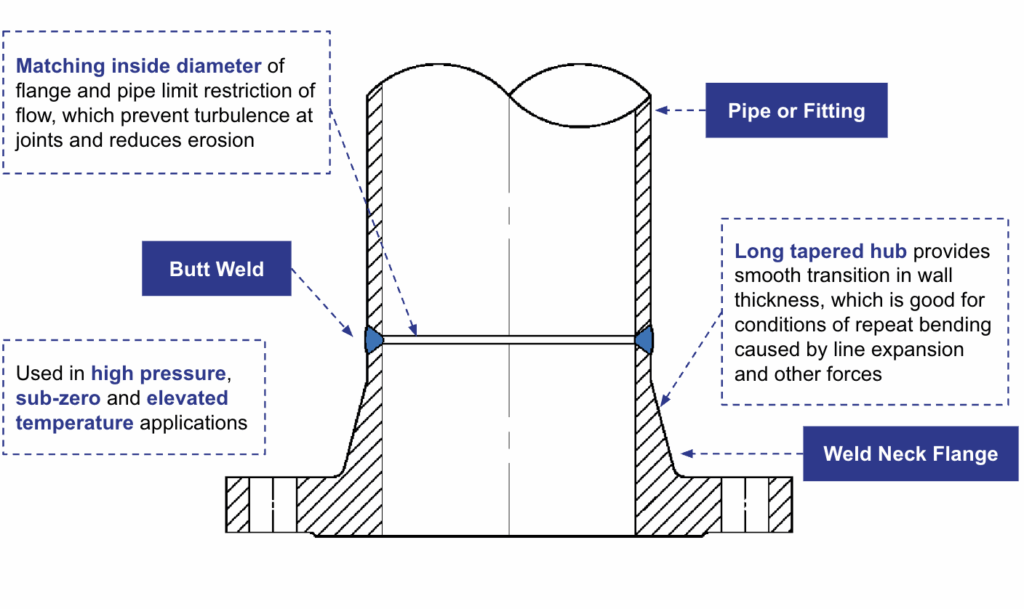

Overview of Weld Neck Flanges

Weld neck flanges (WN flanges) feature a long, tapered hub that transitions smoothly to the pipe wall. This design evenly distributes mechanical stress across the hub and weld area. In addition, this design also minimizes stress concentration and turbulence in the flow.

Features:

Standards: Defined under ASME B16.5 (NPS ½”–24”), ASME B16.47 (NPS 26”–60”).

Pressure Ratings: Available in Classes 150 through 2500, depending on flange size and material.

Materials: Commonly produced in carbon steel (ASTM A105), stainless steel (ASTM A182), low-temperature steel (ASTM A350), and high-alloy steels.

Facings: Raised Face (RF) and Ring-Type Joint (RTJ).

Applications: Commonly used in refineries, offshore platforms, high-pressure steam lines, and chemical or power plants.

Advantages: Excellent strength and fatigue resistance, smooth bore transition minimizes turbulence and erosion.

Limitations: Higher fabrication cost, requires skilled welding and precise alignment; more time-intensive to install compared to slip-on flanges.

Detailed Comparison: Slip-On vs. Weld Neck Flanges

| Parameter | Slip-On Flange | Weld Neck Flange |

|---|---|---|

| Connection Type | Fillet weld on both sides | Butt weld (full penetration) |

| Installation Complexity | Easy to align and install; minimal skill required | Requires precise alignment and skilled welding |

| Weld Type | Two external fillet welds | One butt weld with full penetration |

| Pressure Rating | Typically up to Class 300 | Suitable for Class 150–2500 |

| Temperature Range | Up to ~400°C (750°F) depending on material | Suitable for extreme temperature service (cryogenic to >600°C / 1110°F) |

| Strength & Fatigue Resistance | Moderate strength; limited under cyclic loading | Excellent strength and fatigue resistance |

| Leak Potential | Moderate (under very extreme conditions | Very low; full penetration weld ensures integrity |

| Stress Distribution | Concentrated at the fillet weld joint | Evenly distributed along the tapered hub |

| Vibration Resistance | Fair | Excellent |

| Erosion & Corrosion Resistance | Moderate; welds more exposed | High; smooth bore minimizes turbulence and erosion |

| Inspection (NDT) | More difficult; welds harder to test fully | Easier to inspect (radiography or ultrasonic testing) |

| Alignment Tolerance | Allows small misalignment | Requires perfect alignment during fit-up |

| Fabrication Cost | Lower initial cost | Higher fabrication cost |

| Installation Time | Faster | Slower |

| Maintenance Frequency | May require more frequent inspection | Long service life, minimal maintenance |

| Common Standards | ASME B16.5, ASME B16.47, AWWA C207/C208 | ASME B16.5, B16.47, MSS SP-44 |

| Common Pressure Classes | 150, 300 | 150, 300, 400, 600, 900, 1500, 2500 |

| Typical Face Types | Flat Face (FF), Raised Face (RF) | Raised Face (RF), Flat Face (FF), Ring-Type Joint (RTJ) |

| Application Scope | Low-pressure, low-temperature systems | High-pressure, high-temperature, or critical systems |

| Weight | Lighter | Heavier due to hub |

| Long-Term Reliability | Moderate | Excellent |

How to Choose Between Slip-On and Weld Neck Flanges

Where Slip On Flanges Are Used:

System operates at low or moderate pressure (below 300 psi)

Quick installation and cost-efficiency are priorities

Pipe alignment is difficult, and flexibility is required

Maintenance involves frequent disassembly or access

Application includes cooling lines, water systems, or low-stress process flow

Where Weld Neck Flanges Are Used:

System experiences high pressure or temperature

The design must endure vibration, shock, or cyclic loading

Weld integrity and inspection access are critical

Long service life and minimal leak risk are required

Application includes refineries, offshore platforms, power plants, or chemical processing

Pros and Cons Summary

| Flange Type | Pros | Cons |

|---|---|---|

| Slip-On Flange | – Lower cost and faster installation – Easier alignment – Suitable for low-pressure lines – Available in both raised and flat face designs | – Weaker joint strength – Higher risk of leakage – Limited temperature and pressure range – Not ideal for fatigue or cyclic loading |

| Weld Neck Flange | – Superior mechanical strength – Excellent fatigue and vibration resistance – Ideal for high-pressure, high-temperature service – Smooth flow transition minimizes turbulence | – Higher installation cost – Requires skilled welding – More time-intensive to install |