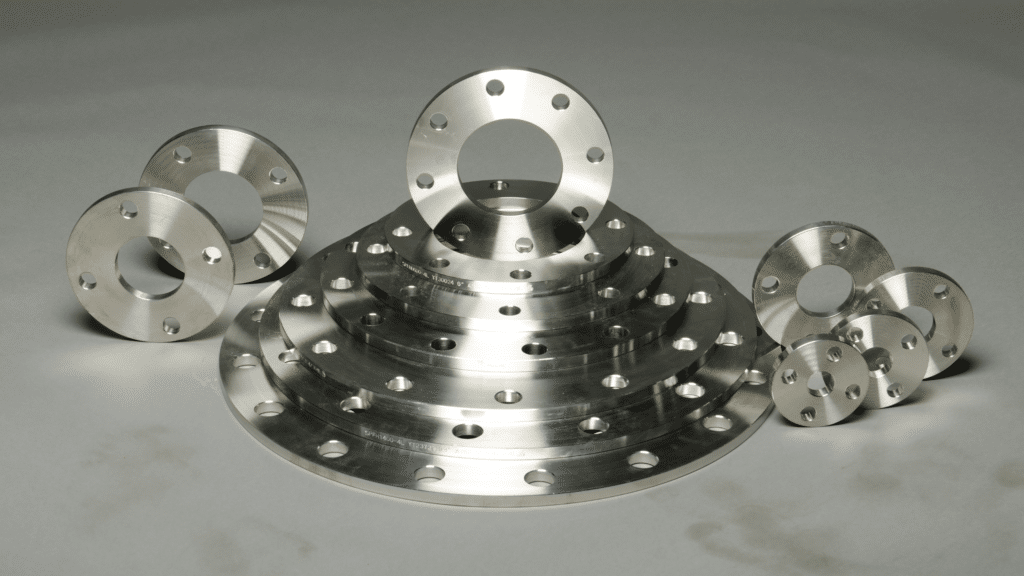

Flanges are crucial piping system components used by various industries, including Agriculture, Exhaust, HVAC, and Water Works. These essential components ensure the reliable and leak-free connection of pipes and equipment. With a wide range of flange types, selecting the right type for your industry can be daunting. In this comprehensive guide, we will explore the key considerations and provide expert insights to help you make informed decisions when choosing the correct flanges for your industry needs.

Understanding the Basics of Flanges:

Flanges are flat, circular discs with evenly spaced bolt holes connecting pipes, valves, or equipment. They act as a sealing mechanism to prevent leaks and ensure the integrity of the piping system. Flanges are available in different materials, sizes, and pressure ratings to accommodate the requirements of various industries.

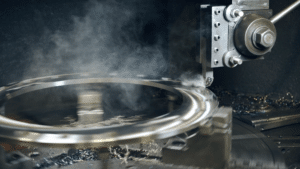

Choosing the Right Flange Material:

The choice of material is crucial when selecting flanges. Stainless steel flanges are an excellent choice for industries requiring robust corrosion resistance, such as offshore applications or those involving corrosive fluids. Stainless steel offers exceptional durability, longevity, and resistance to rust and corrosion. On the other hand, carbon steel flanges are suitable for industries with lower corrosion risks and specific temperature and pressure requirements.

Considering Flange Pressure Ratings:

Pressure ratings are vital for determining the suitable flange class for your industry. Flanges are classified based on their pressure-temperature ratings, which indicate their maximum allowable pressure at different operating temperatures. Selecting flanges with appropriate pressure ratings that align with your industry’s operational requirements is essential to ensure safety and reliability. API International stocks AWWA Class B Steel Blind Flanges that are pressure-rated to 86psi, whereas their AWWA Class E Steel Blind Flanges are pressure-rated up to 275psi.

Assessing Flange Types and Facing:

Different flange types are designed to cater to specific needs. Common types include slip-on flanges, weld neck flanges, blind flanges, lap joint flanges, and socket weld flanges. Each type has its advantages and is suitable for particular applications. Additionally, considering the flange facing is essential to ensure proper sealing. Raised face (RF) and flat face (FF) are two popular facing types, each offering distinct benefits depending on the industry’s demands.

Industry-Specific Considerations:

Every industry has unique requirements regarding flanges. For example, the Agriculture industry may require flanges that can withstand the harsh conditions of irrigation systems, while the HVAC industry may prioritize flanges with excellent insulation properties. Understanding your industry’s specific challenges and demands will help narrow the options and identify the most suitable flanges for your applications.

Partnering with a Reliable Flange Manufacturer and Distributor:

Selecting suitable flanges involves more than just considering the technical aspects. It is equally important to partner with a reliable manufacturer and wholesale distributor that can provide high-quality products and excellent customer service. Look for a company like API International that has a proven track record of delivering flanges to various industries. Their conveniently located warehouses and machine shop capabilities ensure quick distribution and the ability to modify stock items or produce custom products to meet your unique specifications.

Talk to a Sales Representative at API International:

Selecting the correct flanges for your industry requires careful consideration of material, pressure ratings, flange types, and industry-specific needs. Understanding these key factors and partnering with a reputable manufacturer and distributor like API International can ensure reliable, leak-free connections in your piping systems. Remember, when it comes to flanges, precision and expertise matter. Consult with industry professionals and rely on trusted manufacturers to guide you through the selection process. Contact our sales department if you have any questions!