Plate flanges are fabricated by cutting profiles from flat carbon or stainless steel ASTM specified plate. Subsequently, they are machined to precise specifications, including bolt hole patterns and center bores. While forged flanges are shaped under high pressure or force from round or square billets, plate flanges are cut from flat stock (commonly ASTM A36 for carbon steel or ASTM A240 for stainless steel). The finished flanges are typically welded to piping systems where a standardized, economical flanged connection is needed. In practice, the term “plate” most often refers to plate-style slip-on (ring-type) and blind flanges used in waterworks and general industrial applications.

Standards Used For Plate Flanges

The most critical point for buyers and engineers is to recognize that a “plate flange” identifies a specific manufacturing route—cutting from flat stock—rather than a universal dimensional set. The final dimensions, bolt hole patterns, facing types, and pressure-temperature ratings are dictated by the secondary standard to which they adhere, such as ASME B16.5, AWWA C207, or EN 1092-1. Consequently, specifying a flange as ‘plate’ is only the first step in a complete technical procurement.

| Standards Organization | Standard / Specification | Typical Use Environment | Why It Matters |

|---|---|---|---|

| AWWA | AWWA C207 / AWWA C228 | Waterworks service | Common for municipal and industrial water systems. C207 addresses steel pipe flanges for waterworks service, while C228 covers stainless-steel pipe flange joints for water service applications. |

| DIN / EN | DIN EN 1092-1 (PN-rated) | Metric / European systems | Uses PN ratings (e.g., PN10, PN16, PN25) with metric drilling and dimensions for DN piping systems, so bolt patterns and flange geometry differ from ASME Class-rated flanges. |

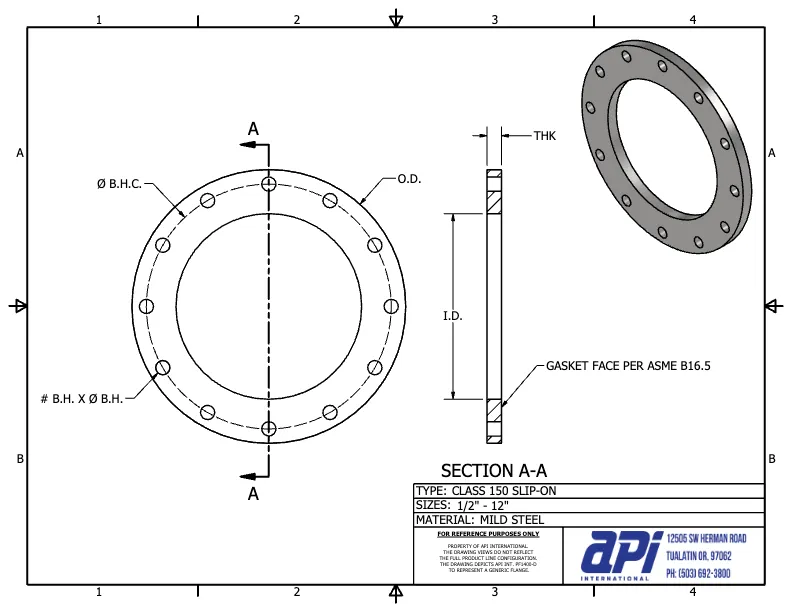

| ANSI/ASME | ASME B16.5 (Class-rated) | Industrial piping (NPS 1/2–24) | Uses ASME pressure classes (e.g., Class 150, 300, etc.) with standardized dimensions, facing options, and bolt patterns for flanged joints in industrial piping systems. |

Different Types of Plate Flanges

Ring-type slip-on plate flange

- A flat ring flange that slips over the pipe OD and is welded to the pipe (common in waterworks and general service).

- Often specified under waterworks ring-type flange categories (for example, AWWA C207 ring-type slip-on)

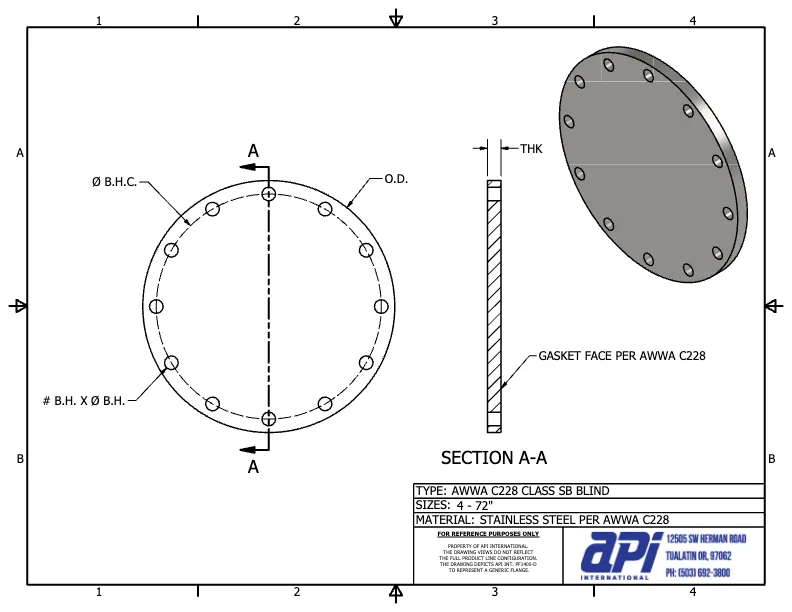

Blind plate flange

- A solid flange (no bore) used to seal the end of a line/nozzle or to create an isolation point.

- Explicitly included under waterworks flange standards (AWWA C207 describes blind flanges)

Exhaust Flanges

- Flat plate connectors used to join sections of ducting or exhaust piping with a bolted, gasketed connection.

- Common in low-pressure airflow and exhaust applications, where the goal is a secure mechanical joint rather than a pressure-rated piping flange.

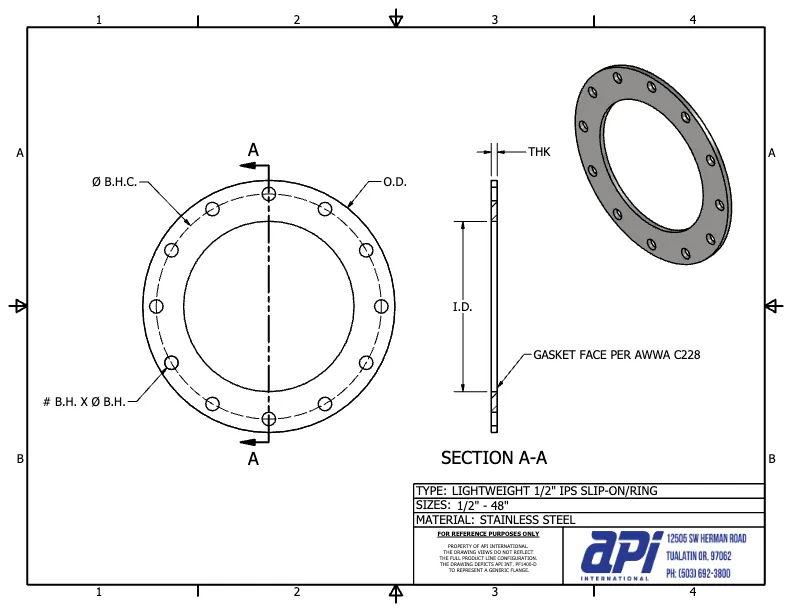

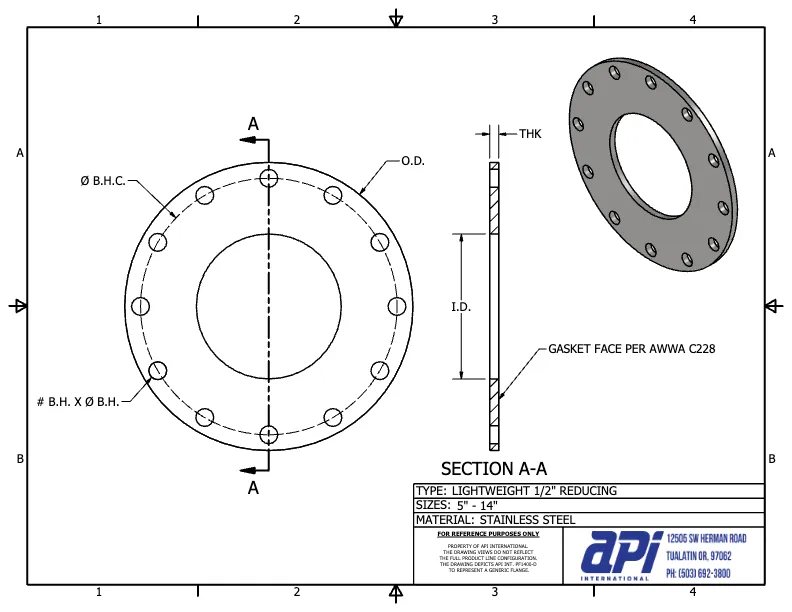

Lightweight Flanges

- Reduced-thickness plate flanges engineered for low-pressure service where full-weight, pressure-rated flanges are unnecessary.

- Typically used on utility and non-critical piping where weight, cost, and ease of handling are priorities.

Reducing / specialty plate flanges

- Reducing flanges are used when you need a bolt pattern and face to match one side, but a different bore size or specialty geometry.

- Commonly used as a transition flange to connect equipment or piping with mismatched sizes or drilling, while keeping one side standard.

What is a Plate Flange Used For?

Plate flanges are utilized wherever a bolted, gasketed joint is required for assembly, maintenance, or equipment tie-in. Common applications include:

- Waterworks piping (pump stations, treatment plants, distribution piping): ring-type slip-on and blind flanges are core categories in AWWA C207.

- Stainless water service: stainless flanged joints built to AWWA C228 for stainless piping systems.

- Low-pressure piping systems: ideal where extreme strength and high-pressure ratings are not required (up to ~300 psi, depending on the standard, material, and temperature).

- Municipal water pipelines: used for water supply, irrigation, and treatment systems.

- Industrial gas pipelines: suitable for distributing natural gas and low-pressure industrial gas (where applicable and permitted by the governing spec).

- Ventilation and exhaust lines: common in HVAC, industrial vents, and exhaust stacks.

- Structural utility connections: for general industrial setups where cost savings and ease of handling matter.

- General industrial piping where the system design basis (pressure, temperature, loads, cyclic service) and the governing spec allow plate-style fabrication.

How Are Plate Flanges Welded?

This process primarily applies to slip-on and ring-type plate flanges, which are secured to the pipe via fillet welding.

Typical slip-on plate flange welding (conceptual)

- The flange is fit over the pipe OD and positioned to the correct stand-off/face alignment (the gap between the pipe end and the flange face) and checked for perpendicular squareness to the pipe axis.

- The attachment is commonly done with fillet weld(s) at the pipe-to-flange junction.

- The exact weld configuration (one-side vs two-side fillet, weld size, inspection/NDE) is dictated by the governing piping code, project specification, and the approved WPS/PQR (welding procedure qualification).

Plate Flanges vs Forged Flanges

A plate flange is profiled from ASTM-specified flat plate; conversely, a forged flange is shaped under high pressure or force from round or square billets prior to final machining.

Comparison table

| Factor | Plate flange (cut from plate) | Forged flange |

|---|---|---|

| Manufacturing | Cut from plate + machined | Forged + machined |

| Typical advantage | Cost-effective, flexible for custom geometry, common in waterworks ring-type | Strong standard choice for high integrity / high load services |

| Typical limitation | May be restricted by spec/service; suitability depends on loads, fatigue, and project code | Often higher cost; may be unnecessary for low/moderate service |

| Where commonly specified | Waterworks ring-type slip-on + blind (AWWA C207/C228) | Many ASME B16.5/B16.47 industrial flange applications |

Why Choose Plate Flanges?

Plate flanges are selected when they align with specific project specifications and service conditions. Key advantages include:

- Cost-effective for the right scope: Cutting from plate is often an efficient manufacturing route for ring-type and blind styles.

- Direct alignment with waterworks practice: Plate-style ring-type slip-on and blind flanges are standard categories in waterworks flange specifications and are widely used on municipal systems.

- Simple, proven connection method: Slip-on plate flanges attach by straightforward fit-up and fillet welding, creating a common bolted, gasketed joint for assembly and maintenance access.

- Custom transitions are practical: Plate machining makes it feasible to build reducing/transition flanges that keep one side standard (bolt pattern/facing) while changing the bore or geometry.

- Material selection supports corrosion control: Plate flanges are commonly produced in carbon steel or stainless steel so the flange material can be matched to water chemistry, environment, and project requirements.

- Best choice when loads/service allow: For low-to-moderate service where high-load forged styles aren’t required by spec, plate flanges can meet project needs without over-specifying.

Common Plate Flange Specification Errors

Use the checks below to avoid fit-up problems and to ensure the flange you order matches the governing standard, rating system, and service conditions.

- Assuming Class 150 drilling equals any Class 150 flange: bolt-hole patterns can be similar, but dimensions and facing details are standard-dependent (ASME vs AWWA vs DIN/EN) and may vary by product type.

- Mixing PN and ASME Class ratings: PN (metric) and ASME Class (inch) are different rating frameworks with different drilling/dimension conventions, and they are not automatically interchangeable.

- Treating pressure rating as a single PSI number: A flange’s rating is not a static value, but a dynamic curve. Allowable pressure is strictly dependent on both material grade and service temperature, while also being influenced by the specific design basis and governing standard. Consequently, it is essential to consult the specific pressure-temperature tables for the exact material and standard in use.”

Conclusion

Plate flanges offer a practical, versatile solution for projects requiring reliable connections and economical fabrication. Our sales team at API International specializes in navigating complex flange requirements to ensure your system meets its design specifications. Explore our comprehensive range of plate flanges in our online product catalog, or contact us for custom options tailored to your unique project needs. Get connected with a dedicated sales representative today, or call us at 503.692.3800.