Flanged connections are flexible piping components that are used to connect piping and other types of equipment while providing controlled movement and vibration isolation.

Common flanged connection types include stainless steel pump connectors and rubber expansion joints. Both are typically installed at pump inlets and outlets, mechanical equipment connections, and locations requiring flexibility, noise reduction, and system protection. While stainless steel pump connectors are designed primarily to manage vibration and minor misalignment in higher pressure or temperature applications, rubber expansion joints offer a broader range of movement, absorbing vibration, managing moderate offset, and accommodating both angular and thermal expansion in applications where temperature and media compatibility allow for elastomeric materials.

Flanged connections help isolate vibration from pumps and rotating equipment, reducing wear on piping systems and connected hardware.

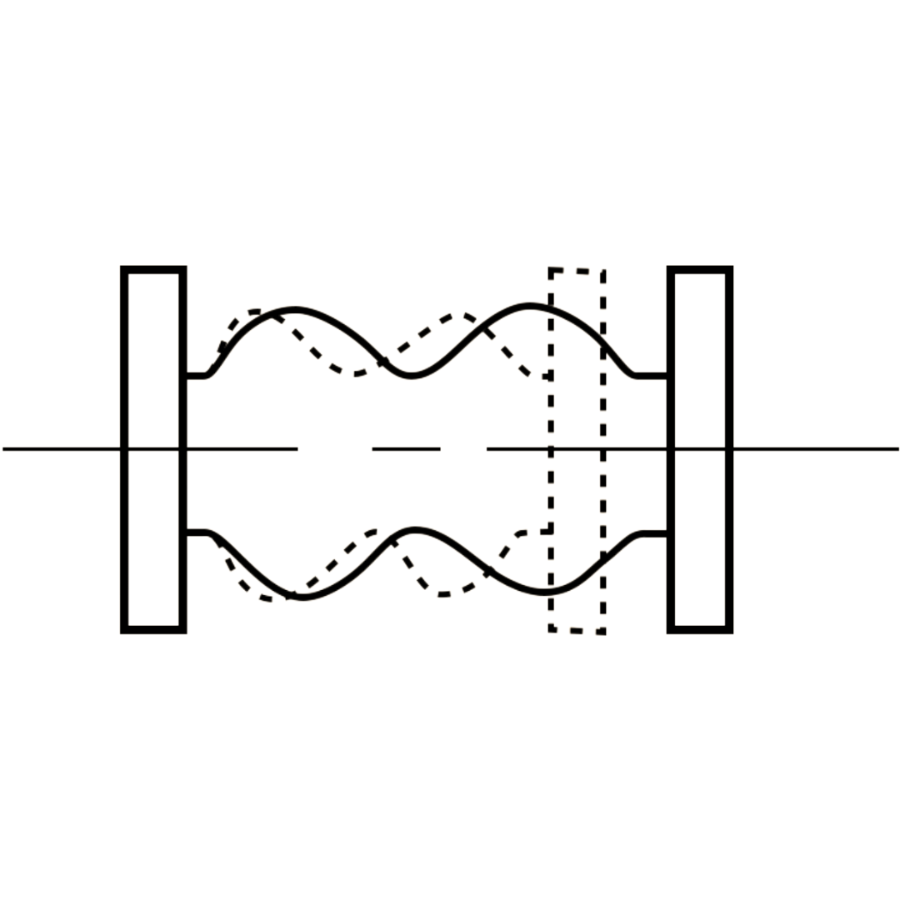

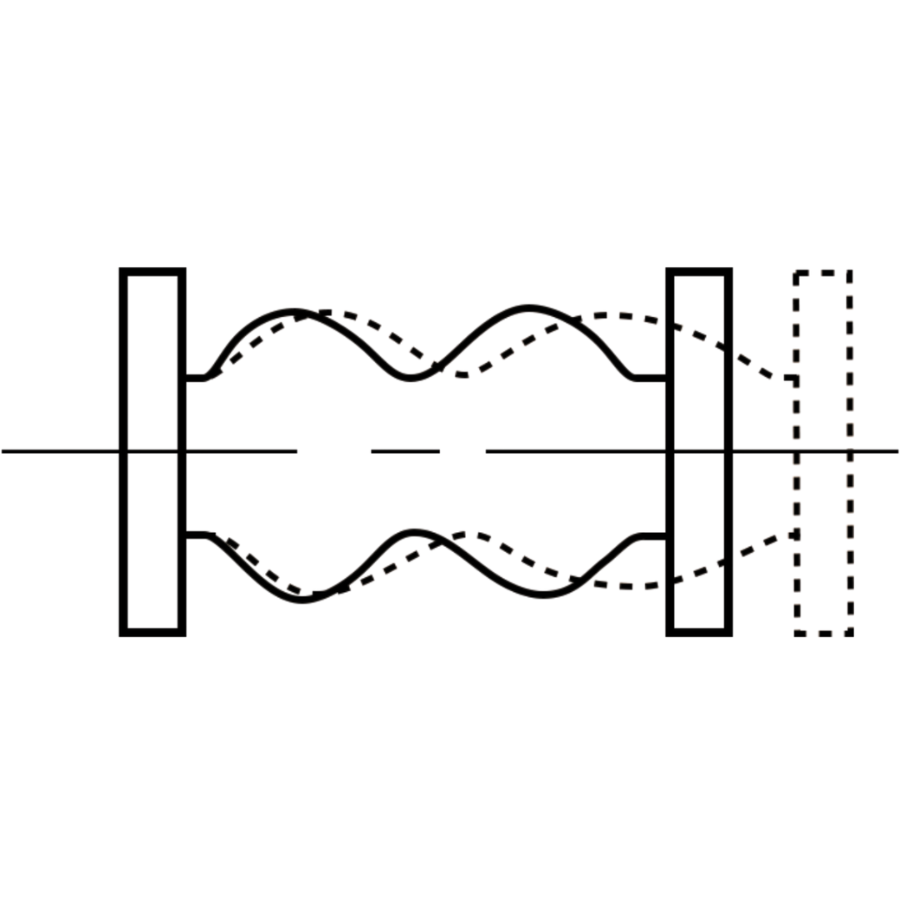

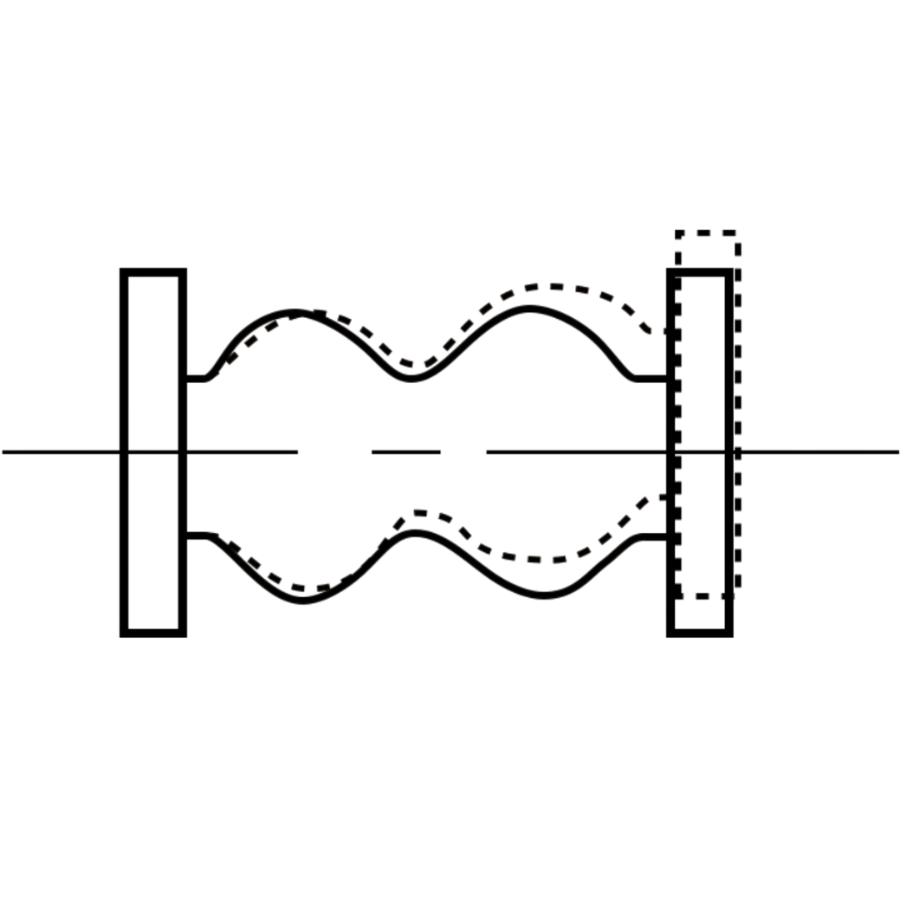

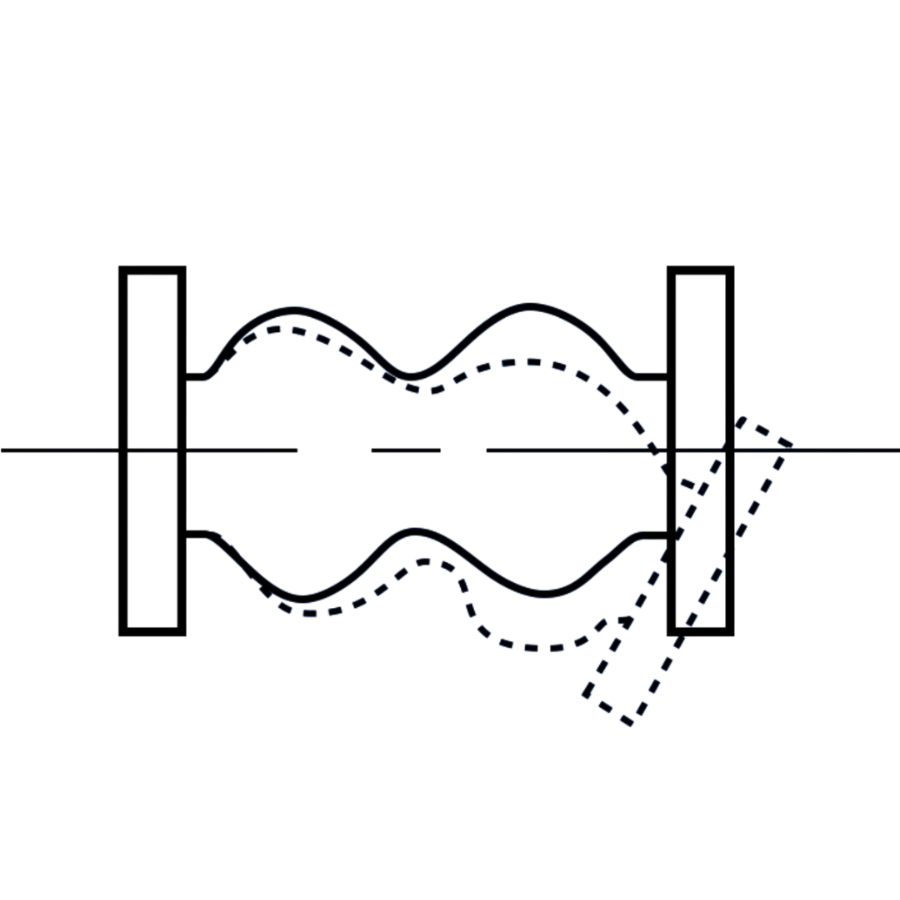

Flanged connections accommodate axial, lateral, and angular movement caused by thermal expansion, settlement, or installation tolerances.

Flanged connections reduce operating noise and mechanical stress within piping and mechanical systems, improving reliability and extending overall service life.

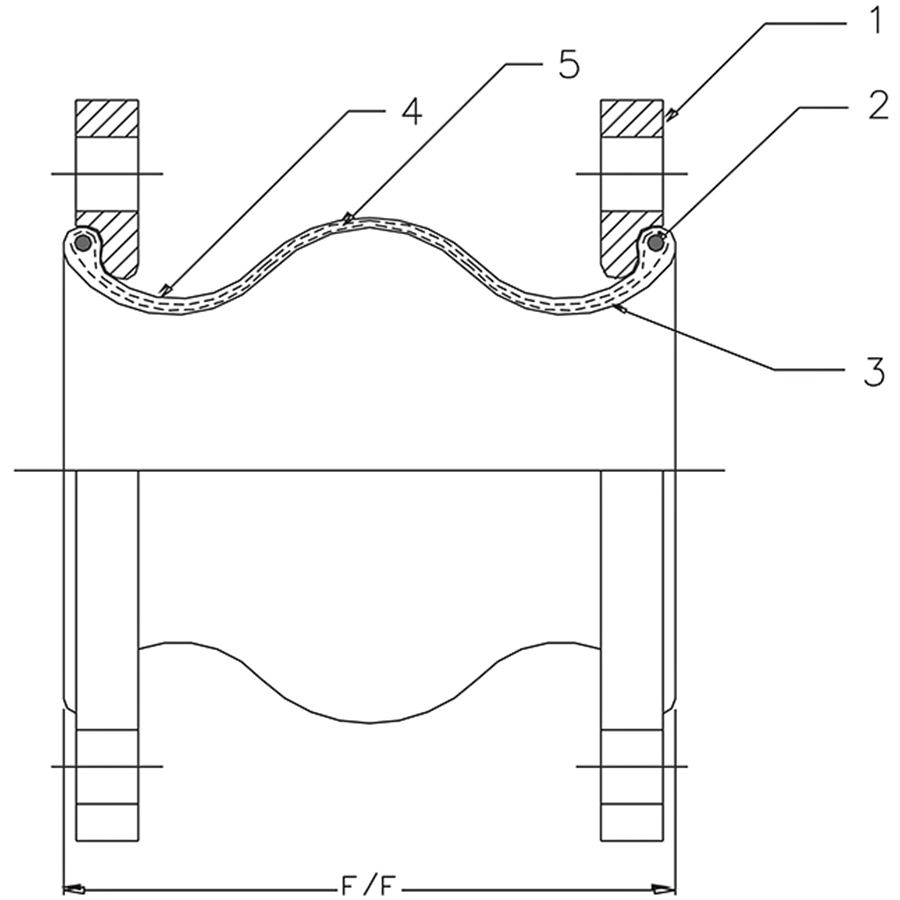

Component Identification

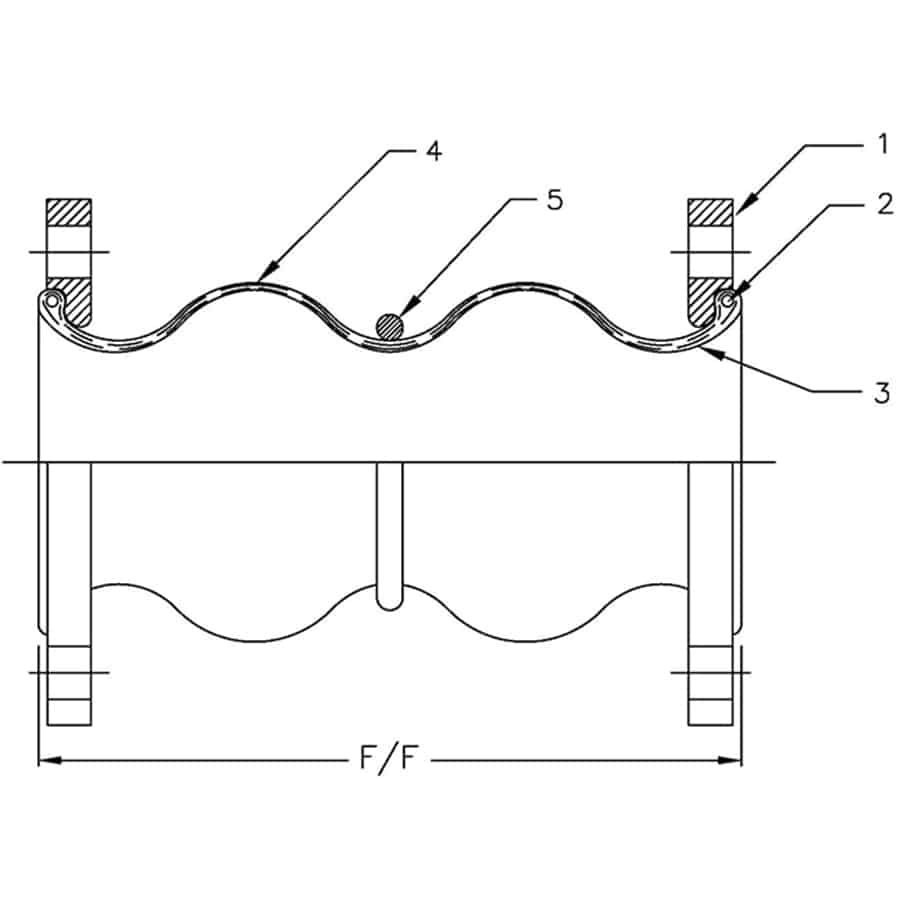

Component Identification

Constructed from stainless steel hose and braid (with steel flanges), these pump connectors are designed to absorb system vibration and feature a Flange × Flange connection style. They are available with single-beamed-braid and single-braided-braided configurations to meet varying pressure requirements. For seamless integration, all flanged models utilize a standard Class 150 (150#) drilling pattern.

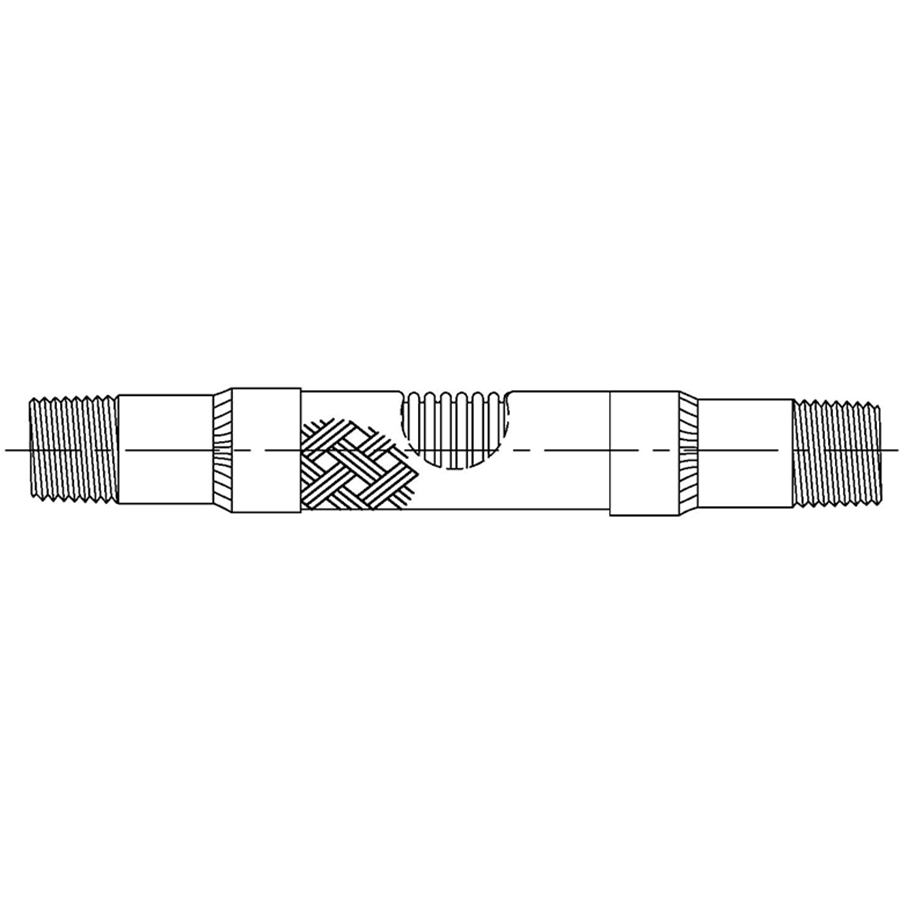

These Stainless Steel Braided Pump Connectors are manufactured with Male X Male threaded connections for easy installation. Hose, braid, and collars are 300 Series grade stainless steel, while the Male X Male ends are National Pipe Thread (NPT) steel.

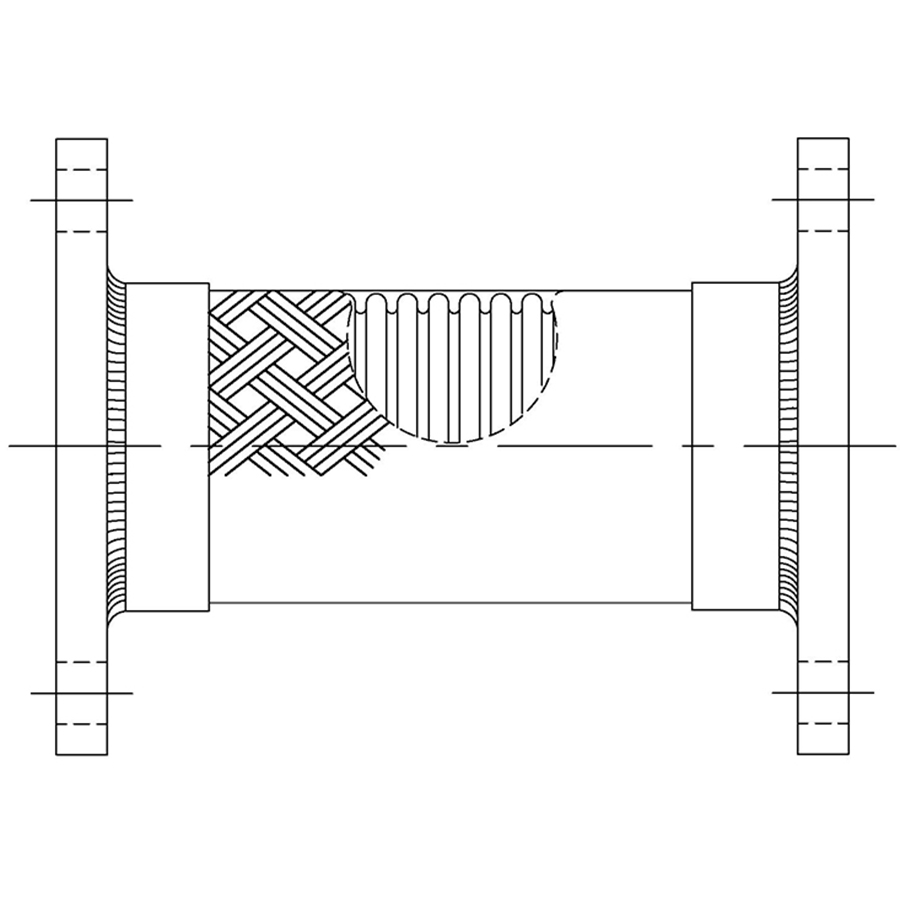

Designed to absorb vibration, noise, and mechanical stress while allowing controlled movement in piping systems.

Allows axial, transverse, and angular movement

Suitable for both suction and discharge lines

ANSI/AMSE Class 150 drilled flanges are standard, but may be customized with DIN PN10/PN16, ANSI/ASME Class 300 drilled flanges, or other bolt patterns as requested.

Multiple elastomer options available for different media and temperature ranges

Provides greater movement capacity than single sphere joints, ideal for systems with higher thermal expansion and misalignment.

Allows axial, transverse, and angular movement

Designed for higher compression and elongation

Reduces vibration, noise, and water hammer

Used in demanding industrial and mechanical systems

ANSI/AMSE Class 150 drilled flanges are standard, but may be customized with DIN PN10/PN16, ANSI/ASME Class 300 drilled flanges, or other bolt patterns as requested.

Combines increased movement capability with union-style connections for easier installation and maintenance.

Designed for higher compression and elongation

Reduces vibration, noise, and water hammer

Used in industrial and mechanical piping systems

Allows axial, transverse, and angular movement

150# F-NPT Malleable Iron Unions

An expansion joint is a flexible piping component which is designed to absorb movement, vibration, and thermal expansion in a piping system. It helps protect pipes, flanges, and connected equipment from stress caused by temperature changes, pressure fluctuations, misalignment, and mechanical vibration.

Metallic expansion joints (bellows) are used in high-temperature and high-pressure applications.

Fabric expansion joints are commonly used in ducting and exhaust systems where large movements occur.

Rubber expansion joints are designed for vibration isolation, noise reduction, and moderate pressure piping systems.

A flange is a rigid mechanical component used to bolt piping sections together. An expansion joint is a flexible connector installed between flanges. Flanges provide connection strength, while expansion joints protect the system from stress and damage.

To order flanged connections from API International, determine your required pipe size, pressure class, material, and any special standards (such as ASME B16.5). Contact API International’s experienced team and they will help you select the right flanged connection for your application.

• Custom Bolt Holes, Overbore, Counterbore, Tapped, Welds, O-ring Grooves, Threads, Special Serrations, Bevels, Chamfers

• Metric Parallel, Metric Tapered, Parallel (BSPP), Taper Thread (BSPT), UN/UNF/UNC Thread, NPT (National Pipe Thread)

• MWD

• Contact API’s engineering department for exact specifications and tolerances.

Plastic: Delrin, POM, Lexan, Nylon 66, Nylon 6, PEEK, PP, PE, Acetal

Rubber: EPDM, Neoprene, Buna-N, Viton

Aluminum: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

Copper: 3600, 3604, 3771

Titanium: 1-28

Steel Series:

• Ductile Iron: ASTM A536

• Carbon/Mild Steel: A105, A36, A516-70, A572-50, etc.

• Stainless Steel:

- 300 Series – 303, 304, 304L, 316, 316L

- 400 Series – 420J2, 430, 434, 442

Special Metals: Hastelloy, Inconel, Incoloy, Duplex 2205, Super Duplex 2507, Chrome Steel, alloys, or their equivalents

Stock Finish, Spiral Serrated (Phonographic), Concentric Serrated, Smooth Finish, Cold Water Finish, MWD, Phonographic

Dipped, Nickel Plating, Zinc Plating (clear, yellow, black, red, blue), Super Agitine, Powder, Painted, Galvanized, Epoxy, Lacquer

Water/Wastewater, Irrigation, Agriculture, HVAC, Marine, Exhaust, Mining, Energy/Power Generation/Oil

• Forged:

- Ring Rolling:

• Materials: Carbon Steel, Stainless Steel, Duplex

• Size: 2–202”

• Cast:

- Centrifugal Casting (Industrial):

• Material: Stainless Steel

- Continuous Casting:

• Material: Stainless Steel

- Sand Casting:

• Material: A536, Stainless Steel, Ductile Iron

- Investment/Lost-Wax/Precision Casting

• Material: Stainless Steel

Machining: Milling, Turning, Facing, Boring, Drilling, Tapping, Counter Sinking, Laser Cutting, Water Jet, Plasma Cutting

| Products | Type | Materials | Size Range |

|---|---|---|---|

| Flanges | Flat-Face, Raised-Face, & Plate: Slip-On/Ring Weld, Neck, Blind, Socket Weld, Orifice, Reducing, Threaded | See Materials List | 5–202″ |

| Gaskets | Molded, Extruded, sheet | EPDM, Buna-N, NBR, Non-Asbestos (GNA), Red Rubber (GRR), Viton | 5–60″ |

| Screens For Filters | Basket Screens and Cone Screens (Perforated, Mesh) | Galv. Carbon Steel, Carbon Steel, Stainless Steel | 6”D x 8’-H |

| Rings | Exhaust Rings (Marmon Flanges for DPF Filters) | Carbon Steel, Stainless Steel, Aluminum | 1–16” |

| Seamless Rolled Rings | Forged | Carbon Steel, Stainless Steel, Aluminum | 1–165” |

| Square Hole Rings | Repair Couplers | Carbon Steel, Stainless Steel, Galvanized, Epoxy Coated | 3–32” |

| Fabricated Assemblies | Weldments, Pipe Spools, Valve Bodies, Silencer Housings | Carbon Steel, Stainless Steel | 2–24” |

| Long/Short Radius Elbows | EN 10253-2–S235, P235GH–P265GH–P265NL and ASTM A234, WPB, WPC/ A420 WPL6, WPL3/ A860 WPHY52/ ASTM A234 WP11, WP22, WP5, WP9–16Mo3 | 304L & 316L Stainless Steel | (45° & 90°): OD: 21.3mm (1/2”)–3048mm (120”) WT: Up to SCH. XXS/160 |

| Miscellaneous | Tubesheets / Diffuser Plates / Baffles / Ferrules / Sleeves / Pins | Carbon Steel, Stainless Steel, Duplex | 5–104” |

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews