This simple feature makes RF flanges reliable in both high- and low-pressure applications, from oil and gas pipelines to general industrial systems. They are designed to work with many gasket types, such as flat ring gaskets or spiral wound gaskets, which gives them excellent versatility. This type of flanges is standardized by ASME B16.5 and ASME B16.47.

1. ASME B16.5 — ½″ to 24″, covers dimensions, pressure classes, and raised face heights.

2. ASME B16.47 (Series A/B) — 26″ to 60″, large-diameter RF flanges for pipelines.

3. AWWA C207 — Covers steel flanges for waterworks service, Classes B through F, where raised face is optional.

1. Classes 150 – 300 → 1/16″ (1.6 mm) raised face height.

2. Classes 400 – 2500 → 1/4″ (6.4 mm) raised face height.

3. Available across ASME pressure classes 150 through 2500, depending on material and size.

Conforms to ASME/ANSI bolt drilling patterns, ensuring interchangeability with standard pipe flanges.

Carbon Steel: ASTM A105, ASTM A350 LF2, ASTM A694

Stainless Steel: ASTM A182 (Grades 304, 304L, 316, 316L, duplex)

Alloy Steels: ASTM A182 F11, F22, F91

Other Options: ASTM A36 plate, nickel alloys, copper alloys for specialty service

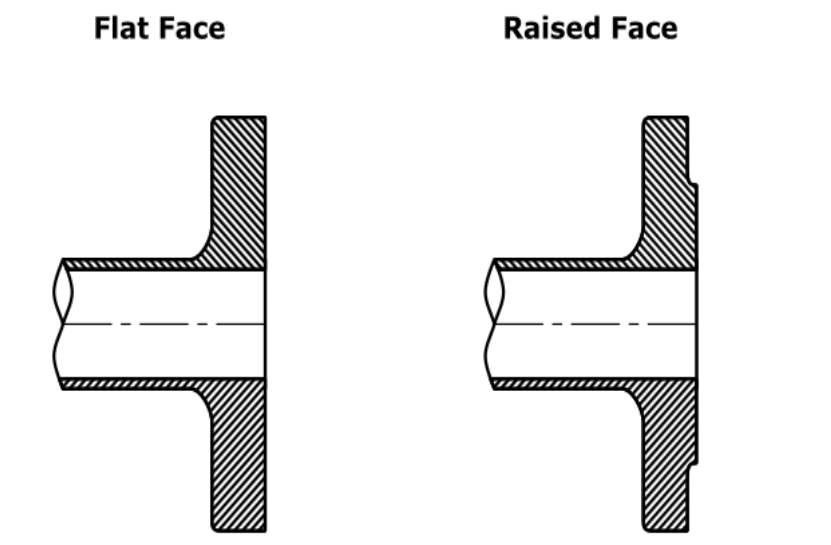

Flange faces determine how a gasket seals between two connected flanges. The flange face (the side connected to another flange) is opposite the hub (the side connected to the pipe).

Raised Face (RF) flanges have a protruding surface area that concentrates the gasket load, which makes them ideal for all pressure systems up to 2500 psi.

Flat Face (FF) flanges provide a continuous gasket contact surface, making installation simpler, and are used for pressure applications up to 300 psi.

Used extensively in upstream, midstream, and downstream operations because RF flanges provide a reliable seal under fluctuating pressures and temperatures.

Common in process piping where corrosive or high-temperature fluids are handled. The raised face design ensures tight sealing with spiral wound or semi-metallic gaskets.

Found in both fossil fuel and nuclear plants, RF flanges are used in high-pressure steam, feedwater, and cooling systems, where safety and durability are critical.

RF flanges connect pipelines and equipment in waterworks systems and offer ease of installation and compatibility with a wide range of gaskets for different service conditions.

Ideal for pipelines carrying aggressive chemicals because RF flanges can be manufactured in alloy or stainless steels.

Slides over the pipe and is welded at both the inner and outer diameters. Easier to install and align than weld neck, but suited for moderate pressure systems.

Solid flange with no bore, used to seal the end of a pipe system or pressure vessel. Allows easy access for inspection or future expansion.

Designed with a long tapered hub that is welded to the pipe, providing excellent strength and stress distribution. Ideal for high-pressure and high-temperature applications.

Has a socket to insert the pipe before welding. Provides good flow characteristics and is used in small-bore, high-pressure lines.

Features internal threads to connect with externally threaded pipes without welding. Common in low-pressure and non-critical applications.

Used with a stub end fitting. The flange itself does not touch the process fluid and can rotate around the pipe, making alignment and assembly easier.

A raised face (RF) flange is a type of pipe flange where the gasket surface is raised above the bolting circle face. This design concentrates sealing pressure on a smaller gasket area, creating a tighter and more reliable seal.

Yes. Raised face flanges are designed to be used with gaskets placed on the raised portion of the face. Sealing is achieved by compressing soft, flat, or semi-metallic gaskets (such as spiral wound or ring gaskets) between the mating flange faces.

RTJ (Ring Type Joint) flanges use a machined groove with a metal ring gasket to achieve a metal-to-metal seal, making them suitable for very high-pressure and high-temperature service.

RF (Raised Face) flanges use a gasket compressed on the raised surface area, making them more common in general industrial applications with moderate to high pressures.

No. Flat face flanges should not be bolted directly to raised face flanges. ASME B31.1 (Power Piping Code) specifies that when connecting flat face cast iron flanges to steel flanges, the raised face must be removed or a full-face gasket must be used. This prevents bending stresses that could crack brittle cast iron.

To order RF flanges from API International, determine your required pipe size, pressure class, material, and any special standards (such as ANSI/ASME B16.5). Contact API International’s experienced team and we will help you select the right flange for your application.

• Custom Bolt Holes, Overbore, Counterbore, Tapped, Welds, O-ring Grooves, Threads, Special Serrations, Bevels, Chamfers

• Metric Parallel, Metric Tapered, Parallel (BSPP), Taper Thread (BSPT), UN/UNF/UNC Thread, NPT (National Pipe Thread)

• MWD

• Contact API’s engineering department for exact specifications and tolerances.

Plastic: Delrin, POM, Lexan, Nylon 66, Nylon 6, PEEK, PP, PE, Acetal

Rubber: EPDM, Neoprene, Buna-N, Viton

Aluminum: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

Copper: 3600, 3604, 3771

Titanium: 1-28

Steel Series:

• Ductile Iron: ASTM A536

• Carbon/Mild Steel: A105, A36, A516-70, A572-50, etc.

• Stainless Steel:

- 300 Series – 303, 304, 304L, 316, 316L

- 400 Series – 420J2, 430, 434, 442

Special Metals: Hastelloy, Inconel, Incoloy, Duplex 2205, Super Duplex 2507, Chrome Steel, alloys, or their equivalents

Stock Finish, Spiral Serrated (Phonographic), Concentric Serrated, Smooth Finish, Cold Water Finish, MWD, Phonographic

Dipped, Nickel Plating, Zinc Plating (clear, yellow, black, red, blue), Super Agitine, Powder, Painted, Galvanized, Epoxy, Lacquer

Water/Wastewater, Irrigation, Agriculture, HVAC, Marine, Exhaust, Mining, Energy/Power Generation/Oil

• Forged:

- Ring Rolling:

• Materials: Carbon Steel, Stainless Steel, Duplex

• Size: 2–202”

• Cast:

- Centrifugal Casting (Industrial):

• Material: Stainless Steel

- Continuous Casting:

• Material: Stainless Steel

- Sand Casting:

• Material: A536, Stainless Steel, Ductile Iron

- Investment/Lost-Wax/Precision Casting

• Material: Stainless Steel

Machining: Milling, Turning, Facing, Boring, Drilling, Tapping, Counter Sinking, Laser Cutting, Water Jet, Plasma Cutting

| Products | Type | Materials | Size Range |

|---|---|---|---|

| Flanges | Flat-Face, Raised-Face, & Plate: Slip-On/Ring Weld, Neck, Blind, Socket Weld, Orifice, Reducing, Threaded | See Materials List | 5–202″ |

| Gaskets | Molded, Extruded, sheet | EPDM, Buna-N, NBR, Non-Asbestos (GNA), Red Rubber (GRR), Viton | 5–60″ |

| Screens For Filters | Basket Screens and Cone Screens (Perforated, Mesh) | Galv. Carbon Steel, Carbon Steel, Stainless Steel | 6”D x 8’-H |

| Rings | Exhaust Rings (Marmon Flanges for DPF Filters) | Carbon Steel, Stainless Steel, Aluminum | 1–16” |

| Seamless Rolled Rings | Forged | Carbon Steel, Stainless Steel, Aluminum | 1–165” |

| Square Hole Rings | Repair Couplers | Carbon Steel, Stainless Steel, Galvanized, Epoxy Coated | 3–32” |

| Fabricated Assemblies | Weldments, Pipe Spools, Valve Bodies, Silencer Housings | Carbon Steel, Stainless Steel | 2–24” |

| Long/Short Radius Elbows | EN 10253-2–S235, P235GH–P265GH–P265NL and ASTM A234, WPB, WPC/ A420 WPL6, WPL3/ A860 WPHY52/ ASTM A234 WP11, WP22, WP5, WP9–16Mo3 | 304L & 316L Stainless Steel | (45° & 90°): OD: 21.3mm (1/2”)–3048mm (120”) WT: Up to SCH. XXS/160 |

| Miscellaneous | Tubesheets / Diffuser Plates / Baffles / Ferrules / Sleeves / Pins | Carbon Steel, Stainless Steel, Duplex | 5–104” |

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews