Gaskets are mechanical sealing components which are used to prevent leaks between two mating surfaces. They are the most commonly used between flanges in a piping system. Their role is to fill surface imperfections, absorb irregularities, and create a strong and long-lasting seal under pressure, temperature changes, and mechanical vibration.

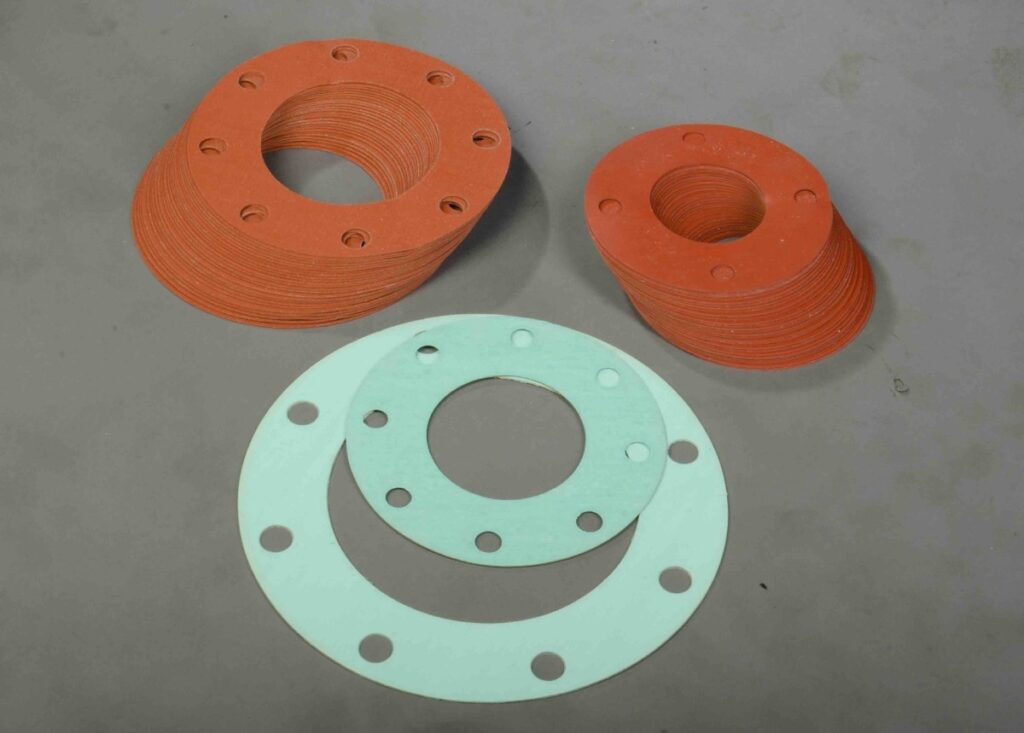

Specific types such as GNA (Non-Asbestos) and GRR (Red Rubber) gaskets are widely used in water, oil, steam, and general industrial applications.

Gaskets are designed to compress between two flange faces. They fill microscopic gaps on the flange faces that would otherwise allow fluids or gases to escape. This compression creates a reliable and leak-tight seal.

Different gasket materials are engineered to withstand specific temperatures, pressures, and chemical environments. Selecting the correct material prevents swelling, breakdown, or premature seal failure in demanding processes.

Gaskets act as a protective interface between metal flanges. They reduce wear and surface damage caused by vibration, mechanical load, and thermal movement. This helps extend the lifespan of equipment and reduces maintenance costs.

Flange gaskets are designed to match the dimensions of standard pipe flanges. Each gasket must fit the flange’s inside diameter, bolt circle, bolt hole size, and outer diameter to create a proper seal. The diagrams below show the key measurements used when selecting a gasket, including:

(ID) Inside Diameter

(OD) Outside Diameter

(BC) Bolt Circle Diameter

Bolt Hole Size (B.H.)

Bolt Hole Count (B.H.C.)

These measurements follow industry standards such as ASME B16.5, AWWA C207, and ASME B16.47, ensuring universal compatibility across piping systems.

| Nominal Pipe Size (I.D.) | ANSI Size I.D. (New Style) | Full Face Gaskets (OD Range) | Ring Gaskets (OD Range) |

|---|---|---|---|

| 0.5 | 0.878 | 3.5–3.75 in | 1.875–2.125 in |

| 1 | 1.313 | 4.25–4.875 in | 2.625–2.875 in |

| 1.5 | 1.943 | 5.0–6.125 in | 3.375–3.750 in |

| 2 | 2.375 | 6.0–6.5 in | 4.125–4.375 in |

| 3 | 3.500 | 7.5–8.25 in | 5.375–5.875 in |

| 4 | 4.500 | 9.0–10.0 in | 6.875–7.250 in |

| 6 | 6.625 | 11.0–12.5 in | 8.75–9.875 in |

| 8 | 8.625 | 13.5–15.0 in | 11.0–12.125 in |

| 12 | 12.75 | 19.0–20.5 in | 16.13–16.625 in |

* This is a simplified reference chart. To view the full gasket dimension table with all sizes and detailed measurements, click the link below.

| Material / Designation / Composition | General Properties | Resistance to: | Attacked by: |

|---|---|---|---|

| Neoprene (CR) – Chloroprene | Good weathering resistance and flame retarding. Good resistance to petroleum-based fluids. | Moderate chemicals and acids, ozone, oils, fats, greases, and many solvents. | Strong oxidizing acids, esters, ketones, chlorinated, aromatic, and nitro hydrocarbons. |

| EPDM (EPM) – Ethylene-propylene-diene-monomers | Excellent ozone, chemical, and aging resistance. Excellent heat resistance. Poor resistance to petroleum-based fluids. | Heat, ozone, strong oxidizing chemicals, and acetone. | Petroleum-based fluids, animal fats, solvents, and greases. |

| Buna-N (NBR) – Nitrile-butadiene | Excellent resistance to petroleum-based fluids. Good physical properties. | Many hydrocarbons, fats, oils, hydraulic fluids, and chemicals. | Ozone (except PVC blends), ketones, esters, aldehydes, chlorinated and nitro hydrocarbons. |

| Silicones (Q, SI) – Polysiloxane | Excellent high and low temperature properties. Good oil resistance. FDA compound. Good physical properties. | Moderate chemicals and acids, ozone, oils, fats, greases, and concentrated sodium hydroxide. | Many solvents, high aromatic hydrocarbons, concentrated acids, dilute sodium hydroxide. |

| SBR (Red Rubber) – SBR – Styrene-butadiene | Good physical properties and abrasion resistance. Poor resistance to petroleum-based fluids. | Most moderate chemicals: wet or dry, organic acids, alcohols, ketones, and aldehydes. | Ozone, strong acids, animal fats, oils, greases, and most hydrocarbons. |

| Viton (FPM) – Hexafluoropropylene-vinylidene fluoride | Excellent oil and air resistance at low and high temps. Excellent chemical resistance. | All aliphatic, aromatic, and halogenated hydrocarbons, acids, animal and vegetable oils. | Ketones, low molecular-weight esters, and nitro-containing compounds. |

| Teflon (TFE) – Polytetrafluoroethylene | Excellent chemical and solvent resistance. Resistant to very high temperatures. | Inert to most chemicals, smooth non-adhesive surface. Easily cleaned. | Acetates, NA-K, and some amino acids. |

| Non-Asbestos (NA) – Aramid fiber + synthetic fibers bonded with NBR | General service water & oil gasket. Pressures to 1595 psi. Temp to 750°F. | Mild acids, alkalies, oils, general chemicals & petroleum derivatives and steam. | Consult customer service for chemical compatibility. |

Used in municipal water lines, treatment facilities, pump stations, and AWWA flange connections to ensure leak-free sealing under moderate pressure.

Gaskets provide reliable sealing in refinery piping, midstream pipelines, separators, and high-pressure process equipment—especially spiral wound and RTJ gaskets.

They are used to handle corrosive chemicals, solvents, and steam within reactors, storage tanks, and process lines.

Flexible rubber and non-asbestos gaskets seal flanges in boilers, chillers, heat exchangers, pump flanges, and general utility piping.

PTFE and compliant elastomer gaskets provide clean, non-contaminating sealing for stainless piping used in hygienic production environments.

Soft gaskets are made from compressible materials like Non-Asbestos (GNA), Red Rubber (GRR), EPDM, Neoprene, PTFE, and other elastomers. They easily conform to flange surfaces and are commonly used in low to medium pressure systems.

Used in: Water, wastewater, HVAC, oil, mild chemicals, steam (low pressure)

Includes:

Semi-metallic gaskets combine a metal core with softer sealing layers, which gives them both strength and flexibility. They offer improved resistance to pressure, heat, and vibration compared to soft gaskets. This type of gaskets is widely used in industrial and refinery applications because of their durability and reliability of a seal.

Used in: Oil & gas, chemical plants, high-temperature or high-pressure pipelines

Includes:

Metallic gaskets are made entirely from metal and built for extreme pressure and temperature conditions. They require matching RTJ (Ring Type Joint) flanges and deliver the most durable sealing performance. These gaskets are common in drilling, petrochemical, and high-integrity pipeline systems.

Used in: High-pressure steam, API pipelines, oilfield wellheads, refineries

Includes:

A flange gasket is a sealing component placed between two flanges to prevent leaks. It fills small surface imperfections and creates a tight, reliable seal under pressure, temperature changes, and vibration.

Leaks are usually caused by improper installation, uneven bolt torque, damaged flange faces, incorrect gasket material, or operating conditions beyond the gasket’s pressure/temperature rating.

Remove the bolts connecting the exhaust flanges, take out the old gasket, clean both flange surfaces, and install a new gasket with even bolt tightening to ensure a proper seal.

Reusing them can cause leaks, uneven compression, or flange damage.

To order flange gaskets from API International, determine your required pipe size, pressure class, material, and any special standards (such as ASME B16.5). Contact API International’s experienced team and we will help you select the right gasket for your application.

• Custom Bolt Holes, Overbore, Counterbore, Tapped, Welds, O-ring Grooves, Threads, Special Serrations, Bevels, Chamfers

• Metric Parallel, Metric Tapered, Parallel (BSPP), Taper Thread (BSPT), UN/UNF/UNC Thread, NPT (National Pipe Thread)

• MWD

• Contact API’s engineering department for exact specifications and tolerances.

Plastic: Delrin, POM, Lexan, Nylon 66, Nylon 6, PEEK, PP, PE, Acetal

Rubber: EPDM, Neoprene, Buna-N, Viton

Aluminum: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

Copper: 3600, 3604, 3771

Titanium: 1-28

Steel Series:

• Ductile Iron: ASTM A536

• Carbon/Mild Steel: A105, A36, A516-70, A572-50, etc.

• Stainless Steel:

- 300 Series – 303, 304, 304L, 316, 316L

- 400 Series – 420J2, 430, 434, 442

Special Metals: Hastelloy, Inconel, Incoloy, Duplex 2205, Super Duplex 2507, Chrome Steel, alloys, or their equivalents

Stock Finish, Spiral Serrated (Phonographic), Concentric Serrated, Smooth Finish, Cold Water Finish, MWD, Phonographic

Dipped, Nickel Plating, Zinc Plating (clear, yellow, black, red, blue), Super Agitine, Powder, Painted, Galvanized, Epoxy, Lacquer

Water/Wastewater, Irrigation, Agriculture, HVAC, Marine, Exhaust, Mining, Energy/Power Generation/Oil

• Forged:

- Ring Rolling:

• Materials: Carbon Steel, Stainless Steel, Duplex

• Size: 2–202”

• Cast:

- Centrifugal Casting (Industrial):

• Material: Stainless Steel

- Continuous Casting:

• Material: Stainless Steel

- Sand Casting:

• Material: A536, Stainless Steel, Ductile Iron

- Investment/Lost-Wax/Precision Casting

• Material: Stainless Steel

Machining: Milling, Turning, Facing, Boring, Drilling, Tapping, Counter Sinking, Laser Cutting, Water Jet, Plasma Cutting

| Products | Type | Materials | Size Range |

|---|---|---|---|

| Flanges | Flat-Face, Raised-Face, & Plate: Slip-On/Ring Weld, Neck, Blind, Socket Weld, Orifice, Reducing, Threaded | See Materials List | 5–202″ |

| Gaskets | Molded, Extruded, sheet | EPDM, Buna-N, NBR, Non-Asbestos (GNA), Red Rubber (GRR), Viton | 5–60″ |

| Screens For Filters | Basket Screens and Cone Screens (Perforated, Mesh) | Galv. Carbon Steel, Carbon Steel, Stainless Steel | 6”D x 8’-H |

| Rings | Exhaust Rings (Marmon Flanges for DPF Filters) | Carbon Steel, Stainless Steel, Aluminum | 1–16” |

| Seamless Rolled Rings | Forged | Carbon Steel, Stainless Steel, Aluminum | 1–165” |

| Square Hole Rings | Repair Couplers | Carbon Steel, Stainless Steel, Galvanized, Epoxy Coated | 3–32” |

| Fabricated Assemblies | Weldments, Pipe Spools, Valve Bodies, Silencer Housings | Carbon Steel, Stainless Steel | 2–24” |

| Long/Short Radius Elbows | EN 10253-2–S235, P235GH–P265GH–P265NL and ASTM A234, WPB, WPC/ A420 WPL6, WPL3/ A860 WPHY52/ ASTM A234 WP11, WP22, WP5, WP9–16Mo3 | 304L & 316L Stainless Steel | (45° & 90°): OD: 21.3mm (1/2”)–3048mm (120”) WT: Up to SCH. XXS/160 |

| Miscellaneous | Tubesheets / Diffuser Plates / Baffles / Ferrules / Sleeves / Pins | Carbon Steel, Stainless Steel, Duplex | 5–104” |

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews