1. What DIN EN 1092-1 Covers

- Nominal sizes (DN)

- Pressure ratings (PN)

- Flange facing types

- Dimensional tolerances

- Bolt hole patterns and counts

2. Nominal Size (DN) and Dimensional Meaning

Common DN sizes include:

- DN25, DN40, DN50

- DN80, DN100, DN150

- DN200 through DN1000+

| DN Size | Approx. Pipe Size | Typical Applications |

|---|---|---|

| DN25 | ~1 in | Instrument lines, small utility piping, compressed air, control systems |

| DN50 | ~2 in | Process skids, water distribution branches, HVAC piping |

| DN100 | ~4 in | General process piping, pump suction and discharge, building services |

| DN150 | ~6 in | Main headers, fire protection systems, chilled water distribution |

| DN300 | ~12 in | Industrial process mains, plant utility distribution |

| DN600+ | 24 in and larger | Transmission lines, cooling water systems, infrastructure pipelines |

3. Pressure Ratings and Their Impact on Dimensions

As PN rating increases:

- Flange thickness increases

- Bolt diameter most likely increases

- Bolt count may increase

- Load-bearing capacity improves

4. Flange Types Under DIN EN 1092-1

| Flange Type | DIN EN Type | Typical Use |

|---|---|---|

| Flat (Slip-On) | Type 01 | General piping connections where ease of installation and alignment are important |

| Lapped | Type 02 / Type 04 | Systems requiring alignment flexibility or frequent disassembly |

| Blind | Type 05 | Terminating or isolating piping systems for maintenance, testing, or future expansion |

| Weld Neck | Type 11 | Higher-pressure or cyclic service where stress distribution and fatigue resistance are critical |

| Threaded | Type 12 | Low-pressure piping systems where welding is not practical or permitted |

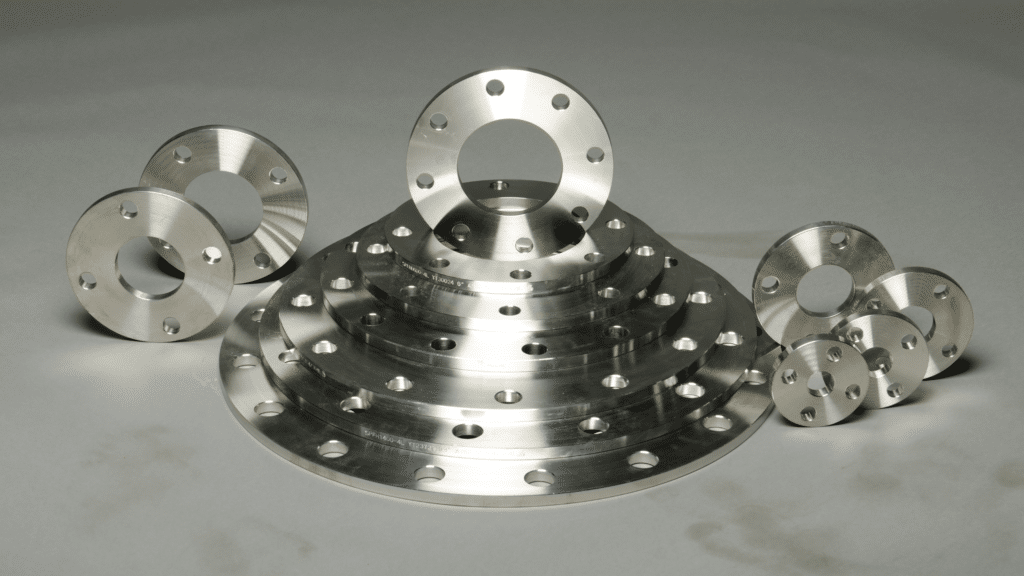

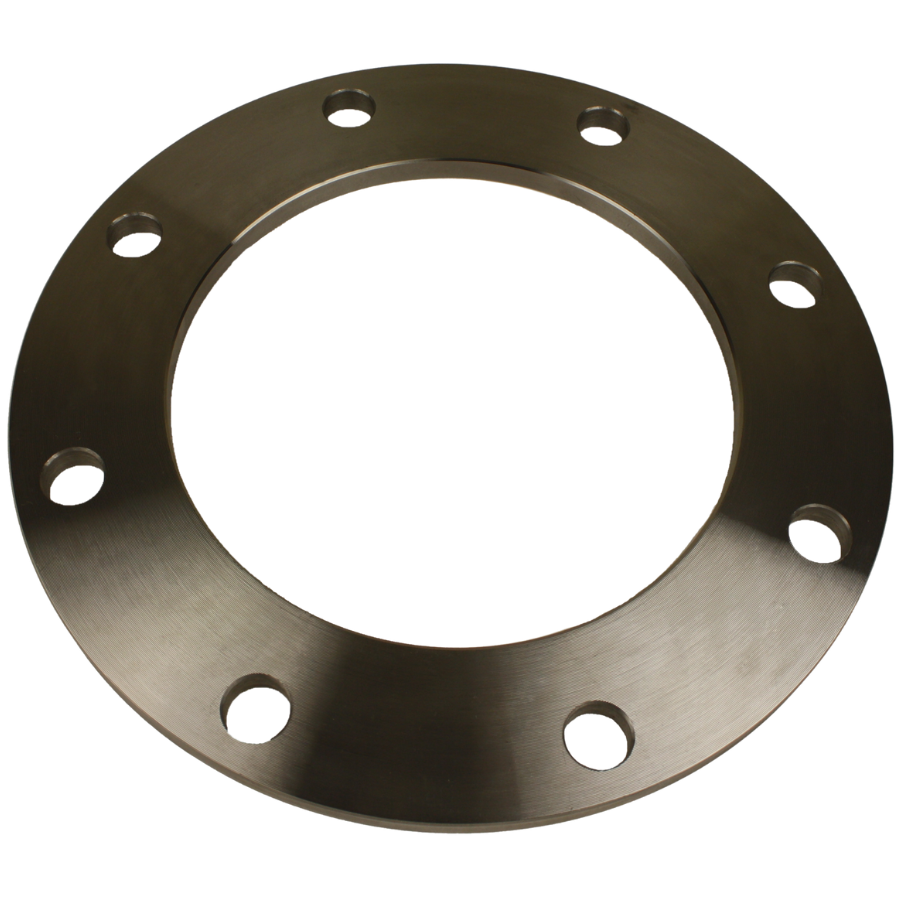

Type 01 (Slip-On) Flanges – API International Manufacturing Scope

At API International, our DIN flange production is focused primarily on Type 01 plate (slip-on) flanges that are manufactured to the DIN EN 1092-1 specification. These flanges are widely used in low-to-moderate pressure piping systems because of their installation simplicity, dimensional consistency, and broad compatibility with metric piping networks.

Type 01 flanges are designed to simply slip over the pipe after which they need to be welded in place. This approach allows efficient alignment during the installation process, and, at the same time, it maintains consistent bolt patterns and sealing geometry. Dimensional tolerances, bolt circle placement, flange thickness, and facing geometry are governed directly by EN 1092-1 tables.

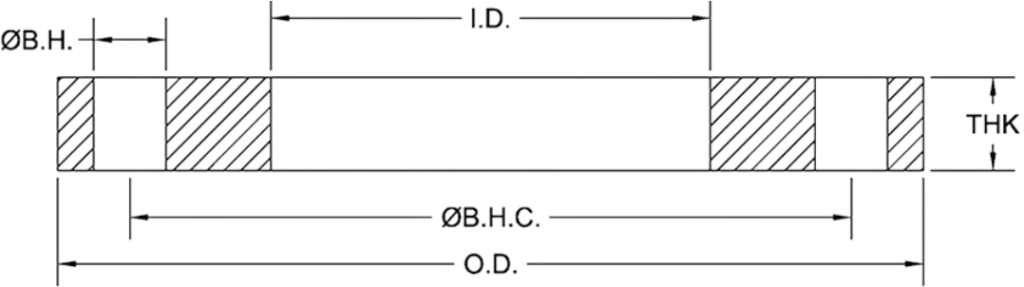

5. Key Dimensional Elements Defined by the Standard

The most critical measurements include:

- Outside Diameter (OD)

- Inside Diameter (ID)

- Flange Thickness (THK)

- Bolt Hole Circle Diameter (BHC / PCD)

- Bolt Hole Diameter

- Number of Bolt Holes

| Nominal Size (DN) | Pressure Class | Outside Diameter (mm) | Bolt Circle (mm) | Flange Thickness (mm) |

|---|---|---|---|---|

| DN50 | PN10 | 165 | 125 | 20 |

| DN50 | PN16 | 165 | 125 | 22 |

| DN50 | PN25 | 165 | 125 | 26 |

| DN150 | PN10 | 285 | 240 | 24 |

| DN150 | PN16 | 285 | 240 | 26 |

| DN150 | PN25 | 300 | 250 | 30 |

6. Bolt Patterns and Sealing Considerations

Under the standard, each DN and PN combination defines:

- Exact bolt quantities

- Bolt hole diameters

- Bolt circle diameters (PCD)

Flange Facing Configurations

7. Materials and Manufacturing

| Material Category | Common Grades | Typical Application |

|---|---|---|

| Carbon Steel | A105, A350 | General pressure piping, structural strength, standard industrial service |

| Stainless Steel | 304, 304L, 316, 316L | Corrosion resistance, chemical processing, food and sanitary systems |