DIN flange pressure ratings are defined through the PN system (e.g., PN10, PN16, PN25) and standardized under EN 1092-1. The standard specifies flange dimensions, bolt patterns, and rating principles for metric piping applications. This article explains the DN/PN designation structure, clarifies how PN relates to pressure capability, and compares the practical differences between PN10, PN16, and PN25.

DN and PN: What They Mean in DIN/EN Practice

DN: Nominal Diameter

Nominal Diameter (DN) is a standardized size designation which is used to keep mating components compatible (pipe, flange, valve, gasket). DN is not guaranteed to equal an exact measured ID/OD; it’s a nominal system used for matching.

PN: Nominal Pressure

PN (Nominal Pressure) is the pressure designation used by DIN/EN/ISO flange systems, and it defines allowable working pressure. Common pressure classes include PN10, PN16, and PN25. Unlike nominal size, the PN class directly affects the structural dimensions of the flange, which include flange thickness, bolt size, and bolt count. The allowable pressure depends on material group and temperature, which EN 1092-1 provides via pressure/temperature (p/T) rating tables.

How EN 1092-1 Connects to Pressure Ratings

EN 1092-1 is the flange “reference standard” for PN-rated steel flanges

EN 1092-1 specifies requirements for circular steel flanges in PN designations (e.g., PN 2.5 up to PN 400) across wide DN ranges, including dimensions, tolerances, bolt sizes, materials, marking, and critically pressure/temperature ratings.

PN is a designation; the pressure–temperature (p/T) tables define the allowable limits at operating temperature.

The same PN rating does not imply the same allowable pressure at elevated temperature. EN 1092-1 includes normative p/T rating tables by material group. These tables show how allowable pressure reduces as temperature rises. Practical takeaway: selecting “PN16” is not enough by itself, meaning that your material and temperature must be checked against EN 1092-1 p/T tables for compliance.

DIN PN10: The Standard Choice For Low-Pressure Utilities

PN10 is the nominal pressure class 10 bar in the DIN/EN flange system. Under EN 1092-1, selecting DN + PN10 also selects a standardized bolt pattern and flange geometry (e.g., bolt circle and thickness) so mating parts match within the PN10 class.

Where PN10 is commonly used:

- Water distribution systems

- HVAC water loops

- Irrigation systems

- Other utility lines where pressure margins are modest

What changes dimensionally (example values)

| Size | Bolt circle (BHC) | Thickness (THK) |

|---|---|---|

| DN100 PN10 | 180 mm (7.09 in) | 22 mm (0.870 in) |

| DN200 PN10 | 295 mm (11.61 in) | 24 mm (0.944 in) |

DIN PN16: The “Default” General Industrial Rating

PN16 is the nominal pressure class 16 bar in the DIN/EN flange system. Under EN 1092-1, selecting DN + PN16 also selects a standardized bolt pattern and flange geometry so mating parts match within the PN16 class.

Where PN16 is commonly used:

- General industrial plants

- Water treatment systems

- Compressed air (moderate)

- Process systems where pressures exceed typical PN10 utility ranges

What changes dimensionally (example values)

| Size | Bolt circle (BHC) | Thickness (THK) |

|---|---|---|

| DN100 PN16 | 180 mm (7.09 in) | 22 mm (0.870 in) |

| DN200 PN16 | 295 mm (11.61 in) | 26 mm (1.030 in) |

DIN PN25: Pressure Class for Higher-Duty Applications

PN25 is the nominal pressure class 25 bar in the DIN/EN flange system. Under EN 1092-1, selecting DN + PN25 also selects a standardized bolt pattern and flange geometry so mating parts match within the PN25 class.

Where PN25 is commonly used

- Higher-pressure steam/condensate segments

- More demanding compressed air service

- Chemical/process duties where PN16 is not sufficient

What changes dimensionally (example values)

| Size | Bolt circle (BHC) | Thickness (THK) |

|---|---|---|

| DN100 PN25 | 190 mm (7.48 in) | 26 mm (1.030 in) |

| DN200 PN25 | 310 mm (12.20 in) | 32 mm (1.260 in) |

A Quick Dimensional Comparison Table

Below are selected slip-on flange examples which show how bolt circle and thickness tend to increase with PN rating.

| PN10 (BHC / THK) | PN16 (BHC / THK) | PN25 (BHC / THK) | |

|---|---|---|---|

| DN100 | 180 mm (7.09 in) / 22 mm (0.870 in) | 180 mm (7.09 in) / 22 mm (0.870 in) | 190 mm (7.48 in) / 26 mm (1.030 in) |

| DN150 | 240 mm (9.45 in) / 24 mm (0.944 in) | 240 mm (9.45 in) / 24 mm (0.940 in) | 250 mm (9.84 in) / 30 mm (1.180 in) |

| DN200 | 295 mm (11.61 in) / 24 mm (0.944 in) | 295 mm (11.61 in) / 26 mm (1.030 in) | 310 mm (12.20 in) / 32 mm (1.260 in) |

| DN250 | 350 mm (13.78 in) / 26 mm (1.024 in) | 355 mm (13.97 in) / 29 mm (1.150 in) | 370 mm (14.57 in) / 35 mm (1.380 in) |

| DN300 | 400 mm (15.75 in) / 26 mm (1.024 in) | 410 mm (16.14 in) / 32 mm (1.260 in) | 430 mm (16.93 in) / 38 mm (1.500 in) |

| DN400 | 515 mm (20.28 in) / 32 mm (1.260 in) | 525 mm (20.67 in) / 38 mm (1.500 in) | 550 mm (21.65 in) / 48 mm (1.890 in) |

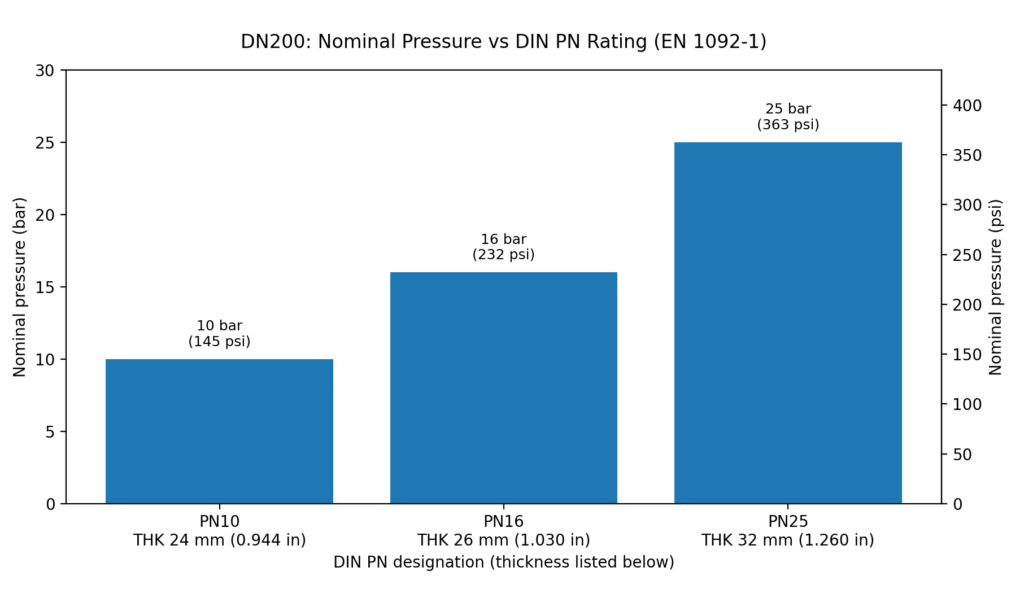

Thickness Growth With PN Rating (DN200 Example)

The following chart illustrates DN200 slip-on flange thickness growth across PN10, PN16, and PN25.

DIN PN vs ASME/ANSI “Class”

Similar purpose, different system (not interchangeable)

PN is sometimes informally compared to ANSI / ASME pressure class (e.g., “PN16 ≈ Class 150”); these comparisons are approximate and not suitable for interchangeability.

- DIN/EN uses PN (nominal pressure designation in bar) and relies on EN 1092-1 p/T tables by material group.

- ASME B16.5 uses pressure classes (Class 150/300/600…) that are defined by pressure–temperature rating tables, not by a single pressure number.

* Even when pressure capability seems “similar,” bolt patterns, facing details, and dimensions differ, so DIN and ANSI / ASME flanges are not physically interchangeable.

Conclusion

DIN PN ratings (PN10, PN16, and PN25) standardize flange selection and interchangeability under EN 1092-1. Final specification should always confirm pressure–temperature limits and dimensional compatibility for the intended service. At API International, Inc., we stock PN-rated steel and stainless steel slip-on flanges manufactured to the Deutsches Institut für Normung (DIN) EN 1092-1 specification. Choose from a wide range of slip-on, ring-style flanges sized according to DIN metric standards available in DIN-PN10, DIN-PN16, and DIN-PN25. If our standard flanges don’t meet your specific requirements, our Custom Machining Shop provides precision manufacturing of custom parts as well as modifications to stock items.