Flanges are fundamental components in piping, pressure vessels, and countless mechanical systems. They join pipes, valves, pumps, and equipment into safe, reliable, and functional systems. Flanges are typically attached by welding, threading, or lapping, and are considered the second most common joining method after welding. Without proper flange selection and installation, industries risk costly leaks, downtime, and safety failures. This article explains what flanges are, how they function, their components, connection methods, and why their design is central to system reliability.

1. The Flange and Its Purpose

A flange is a projecting rim or collar which is designed for strength, alignment, or attachment. In piping systems, flanges connect two sections of pipe or equipment in a way that allows for both secure sealing and easy assembly and disassembly.

Key purposes include:

- A flange creates a leak-proof seal, even under high pressures and extreme temperatures.

- It allows for disassembly for inspection, maintenance, or replacement without cutting or destroying the piping system.

- It also provides standardized connection points so components from different manufacturers can fit together.

Most flanges use bolts and a gasket to achieve a tight, leak-free seal.

2. Components of a Flange Connection

A bolted flange joint is made up of several elements which work together to maintain integrity:

1. Flange Faces

- The mating surfaces that compress a gasket between each other creating the seal.

- Can be flat face, raised face, or ring-type joint, depending on application.

2. Gasket

- A gasket is placed between serrated flange faces to create a seal for joining two pieces, thus preventing fluid or gas escape.

- It must be compressed to the correct stress to maintain sealing under pressure and temperature changes.

3. Bolts, Studs, Nuts, and Washers

- These parts provide the clamp load that compresses the gasket and holds the joint together.

- Correct tightening (often in a star or cross pattern) is important to uniform pressure.

4. Alignment and Flatness

- Flange faces must be parallel, aligned, and have no defects to avoid leaks.

5. Lubrication

- Reduces friction in threads and ensures torque translates effectively during bolt preload.

6. Bolts, Nuts, and Washer Coatings

- Bolts, nuts, and washers may be coated (e.g., zinc-plated or hot-dip galvanized) to add protective layers, thereby increasing the life cycle of the fastener in corrosive environments.

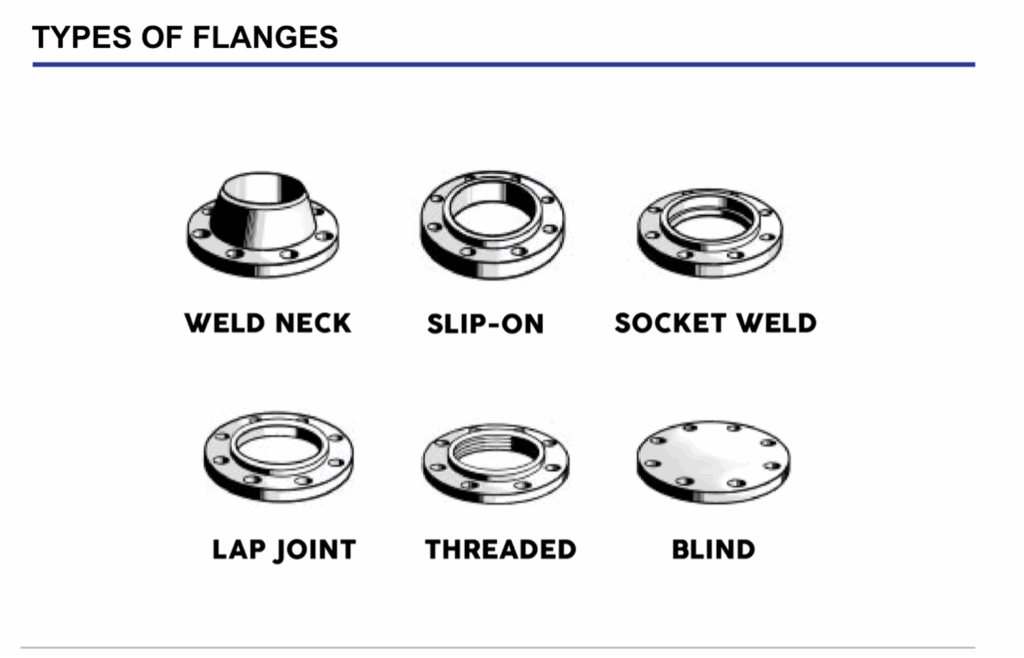

3. Methods of Flange Connection to the Pipe

Flanges can be attached to pipes or equipment in different ways depending on application, pressure, and size:

- Butt-welded with a tapered hub to the pipe.

- Provides excellent strength and stress distribution.

- Best for high-pressure, high-temperature systems.

- Slides over the pipe and is then fillet-welded, typically in two places (along the ID of the flange to the edge of the pipe and the hub of the flange to pipe OD).

- Not as strong as a weld neck.

- Pipe is inserted into a socket and fillet-welded.

- Common in small-diameter, moderate-pressure systems.

- Solid plate used to block off or seal a pipe end.

- Used for pressure testing or system closures.

- Screwed onto threaded pipe.

- Ideal when welding is impractical.

- Limited to low-pressure applications.

- Used with a stub end; flange is not welded to the pipe.

- Allows flange rotation for easy bolt hole alignment.

4. The Flange Connection Process

The flange joint works through controlled compression of the gasket:

- Attachment: Flanges are first welded, threaded, or slipped onto the pipe ends.

- Positioning: A gasket is inserted between the two flange faces.

- Bolting: Bolts are inserted and tightened in sequence to create even pressure.

- Sealing: As bolts tighten, the gasket deforms slightly, filling serrations on the flange faces and creating a seal.

When properly assembled, the result is a mechanically strong, leak-proof joint capable of handling the intended pressure and temperature conditions.

5. Functions and Benefits of Flanges

- Leak-Proof Seals: Prevent costly and dangerous leaks in fluid or gas systems.

- Mechanical Strength: Provide structural integrity to the piping network.

- Maintenance Access: Allow disassembly without destroying pipe sections.

- Versatility: Connect dissimilar materials or terminate a line.

- Standardization: International standards (ANSI/ASME, AWWA, DIN, etc.) ensure compatibility across manufacturers.

6. Standards and Best Practices

Flange joints are governed by following standards:

- ANSI/ASME B16.5 – Defines dimensions, pressure classes, and materials for flanges (½” to 24″).

- ANSI/ASME B16.47 – Covers large-diameter flanges above 24″.

- AWWA C207 / C228 – Covers flanges for waterworks and industrial systems.

- MSS SP-44 – Manufacturers Standardization Society standard, used in steel pipelines.

- API 6A – American Petroleum Institute standard, used in high-pressure oilfield applications.

- DIN – German Institute for Standardization, widely used internationally and in maritime applications.

- JIS – Japanese Industrial Standard, widely applied in Japan and maritime industries.

- AS – Australian Standard for flanges.

- UNI – Italian Standard for flanges.

Best practices include:

- Using the correct gasket for the service conditions.

- Following proper bolt-tightening sequences.

- Avoiding reuse of gaskets.

- Inspecting flange faces for damage or misalignment.

7. Conclusion

By understanding how flanges work, industries can ensure leak-tight systems, reduced maintenance costs, and safe operations. Our sales team at API can answer any questions about your flange requirements. Depending on its application, they can also recommend alternative products that may be better suited for your system. We also provide custom flange solutions tailored to your project specifications. Get connected with a dedicated sales representative today! Or call us: 503.692.3800