1. What Are ASME/ANSI Flanges and How Do They Work?

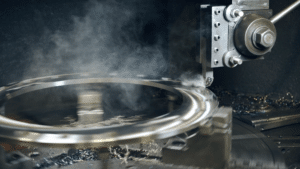

Bolting Mechanism:

- Bolts tighten both flanges together.

- Compression presses the gasket firmly into the flange face.

- The connection forms a reliable, leak-proof seal.

For a more detailed explanation, see our guide on how ANSI/ASME flanges work.

2. ASME B16.5 and B16.47 Standards

| Feature | ASME B16.5 | ASME B16.47 |

|---|---|---|

| Size Range | ½″ – 24″ | 26″ – 60″ |

| Pressure Classes | 150–2500 | 75–900 |

| Series | None | Series A & B |

| Typical Use | General industrial piping | Large diameter pipelines |

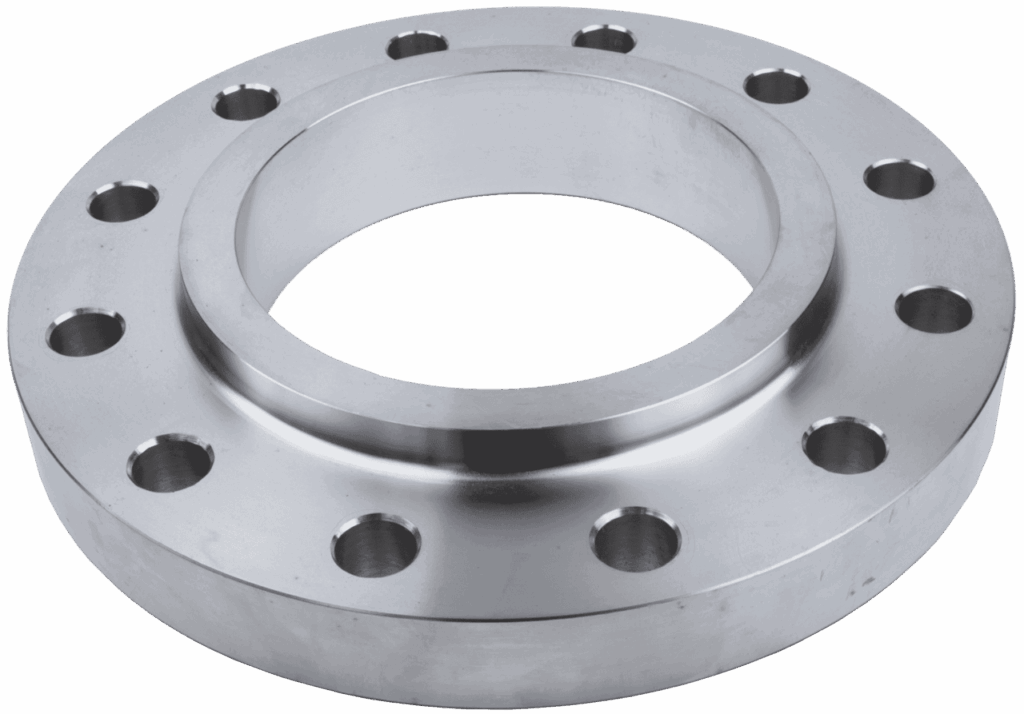

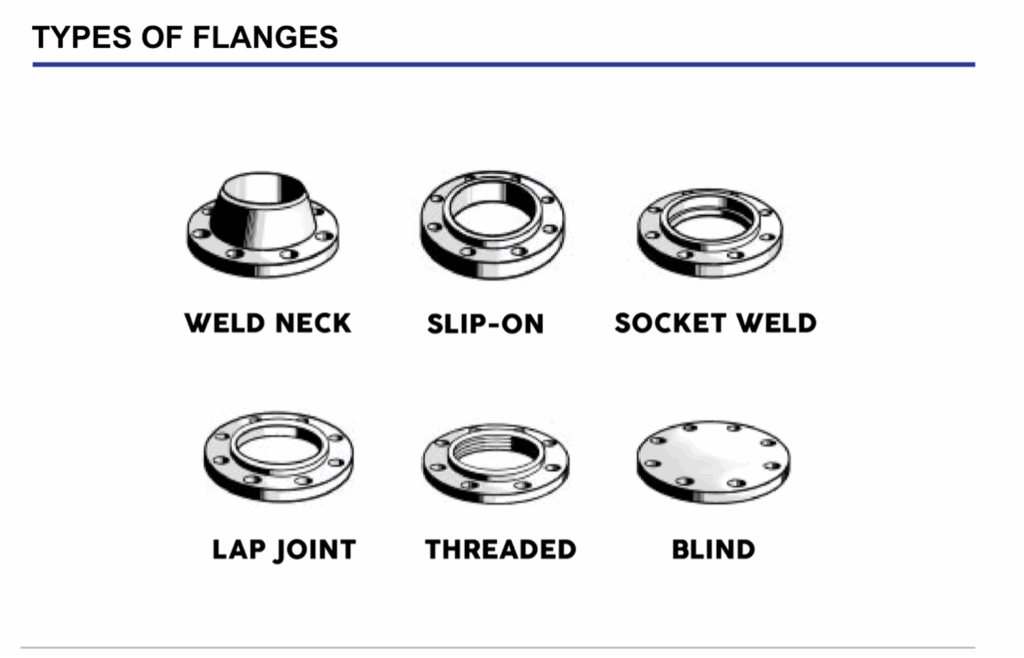

3. Standard Types of ASME/ANSI Flanges

Table: Common ASME/ANSI Flange Types

| Flange Type | Description | Typical Use |

|---|---|---|

| Weld Neck (WN) | Long tapered neck, butt-welded | High pressure, high temperature |

| Slip-On (SO) | Slides over pipe, fillet welded | Low–medium pressure |

| Blind (BL) | Solid plate to close pipeline | Testing, isolation |

| Socket Weld (SW) | Pipe inserted into socket, fillet welded | Smaller pipe sizes, high pressure |

| Lap Joint (LJ) | Two-piece system with stub end | Systems requiring frequent dismantling |

| Threaded (TH) | Internal thread for screw-on connection | Low pressure, non-weld applications |

| Reducing Flange | Different bore size | Pipe size transitions |

4. ASME Pressure Class Chart

ANSI/ASME Pressure Classes (Carbon Steel A105)

(Approximate values, at 100°F)

| Class | Max Pressure (psi) | Conditions |

|---|---|---|

| 150 | 285 psi | Low pressure at near-ambient temperatures. |

| 300 | 740 psi | Moderate pressure with mild temperature demands. |

| 400 | 990 psi | Higher pressure under steady temperature conditions. |

| 600 | 1,480 psi | High pressure combined with elevated temperatures. |

| 900 | 2,220 psi | Very high pressure and increased thermal stress. |

| 1500 | 3,705 psi | Severe pressure loads with temperature fluctuation. |

| 2500 | 6,170 psi | Extreme pressure where maximum rigidity is required. |

5. Materials Used for ASME/ANSI Flanges

1. Carbon Steel (A105, A350)

Suitable for general industrial service

Cost-effective with reliable strength

Performs well under moderate pressure and temperature

2. Stainless Steel (ASTM A182, 304/304L, 316/316L)

Provides strong corrosion resistance

Appropriate for chemical and food-grade environments

Maintains integrity at elevated temperatures

3. Duplex & Super Duplex (2205, 2507)

High mechanical strength with reduced weight

Excellent resistance to pitting and chloride attack

Used in offshore, marine, and high-salinity conditions

4. Nickel Alloys (Inconel, Monel, Hastelloy)

Exceptional resistance to aggressive chemicals

Stable under high heat and thermal cycling

Preferred for demanding, high-temperature corrosive environments

6. Applications of ASME/ANSI Flanges in Industrial Piping

- Oil & Gas Pipelines: Transporting petroleum products under extreme pressures.

- Chemical Processing: Resistant to corrosion and chemical exposure.

- Power Generation: Steam, cooling water, pressure vessels.

- Water & Wastewater: Municipal piping networks and treatment plants.

- Manufacturing & Industrial Facilities: Process lines, compressed air systems, mechanical equipment.

- HVAC Mechanical Systems: Chilled water, steam, hydronic heating loops.

7. Benefits of ASME/ANSI Flanges

ASME/ANSI flanges offer several operational and engineering advantages:

- Interchangeability: Globally recognized standards for flanges ensure compatibility across different manufacturers.

- High-pressure reliability: Designed to perform safely under Class 150–2,500 pressure ratings.

- Easy installation & removal: There is no need for cutting or welding pipe during maintenance.

- Material versatility: Available in carbon steel, stainless steel, duplex, nickel alloys, and more.

- Wide industrial use: From petrochemical plants to municipal water systems, standardized flanges provide dependable operation.

8. How to Choose the Right ASME/ANSI Flange

- Identifying the required pressure class: The class should correspond to the system’s operating pressure and temperature, using standard ratings such as 150, 300, 400, 600, 900, 1500, and 2500.

- Selecting a suitable flange design: Weld neck, slip-on, blind, and threaded configurations each support different service conditions and installation requirements.

- Choosing the appropriate material: Options like carbon steel, stainless steel, duplex, and nickel alloys are selected based on corrosion exposure, temperature limits, and media compatibility.

- Matching pipe size and schedule: Proper alignment requires the flange to match the pipe’s outside diameter and wall thickness.

- Determining the correct gasket and face type: Raised Face (RF), Flat Face (FF), and Ring-Type Joint (RTJ) styles offer different sealing characteristics depending on system demands.