Flanges play an essential role in connecting pipes, valves, pumps, and other piping equipment in a way that allows disassembly and maintenance. Slip-on flanges are widely used because of their ease of installation, moderate strength, and comparatively low cost. Below, we provide more information on what slip-on flanges are, their specifications, advantages, applications, and comparisons with other flange types.

1. What Are Slip-On Flanges

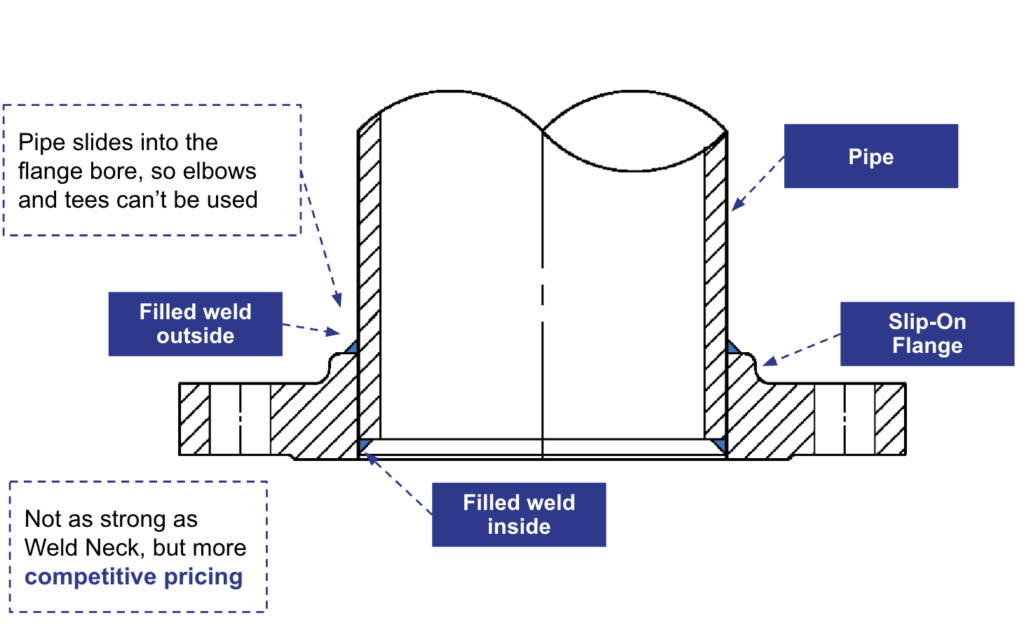

A slip-on flange (sometimes abbreviated as “SO flange”) is a type of flange that is slipped over the outside of a pipe and then welded both inside and outside to provide strength and sealing.

Key characteristics:

- The flange has an inner diameter slightly larger than the pipe’s outer diameter, which allows it to “slip on” (slip over the pipe for proper positioning for welding).

- After the flange is positioned on the pipe, it is tack-welded to hold it in place. Final fillet welds are then applied on both the inside and outside to secure the joint.

- Slip-on flanges can come with a hub (a raised cylindrical extension) or without a hub, depending on design preference and needs.

- Slip-on flanges are easier and cheaper to machine, align, and install compared to some other flange types.

2. Global Standards for Slip-On Flanges

2.1. AWWA Standard (USA)

- AWWA C207 / C228: This is a standard for steel pipe flanges used in waterworks (municipal water and wastewater systems).

- The standard defines different pressure classes: A (50 psi), B (86 psi), D (150/175 psi), E (275 psi), and F (300 psi).

- In AWWA C207, the ring-type slip-on flanges are dimensioned for sizes 4 in. through 144 in for waterworks use.

- The standard allows interchangeable hub or hubless types as long as dimensional requirements are met.

Because AWWA flanges are intended for water service, their maximum typical pressure is significantly less than many industrial ANSI flanges.

2.2. ANSI / ASME (USA)

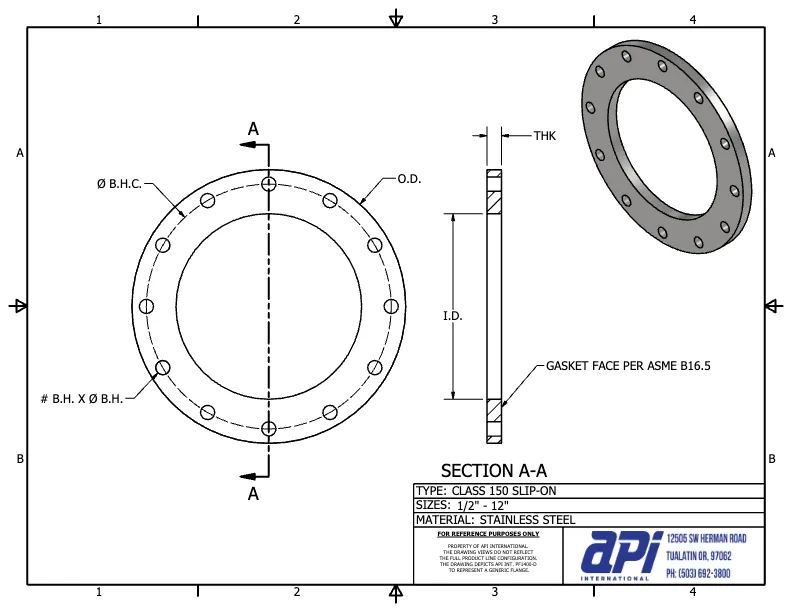

- ANSI/ASME B16.5: This standard covers pipe flanges and flanged fittings from NPS ½ inch through 24 inch, in pressure ratings from 150 to 2,500 lb. The specification includes dimensions for slip-on flanges along with drilling pattern, thickness, hub length, etc.

- ANSI/ASME B16.47: This standard applies to larger flanges (beyond 24″), and also includes slip-on type flanges.

2.3. ASTM (USA)

ASTM standards are more about material properties than flange geometry. Common material specifications for slip-on flanges include:

- ASTM A105: Carbon steel forgings for flanges, valves, and fittings up to ~425 °C, widely used for slip-on flanges.

- ASTM A182: Standard for high-temperature, corrosion-resistant alloy and stainless steel forgings used for flanges (including slip-on types) in more aggressive or high-temperature environments.

2.4. DIN (Europe)

- DIN EN 1092-1: This European standard covers circular flanges with various types of profiles using metric nominal sizes and includes slip-on style (type 01 and type 12). The standard uses metric nominal sizes (DN) and pressure ratings in “PN” classes (e.g. PN10, PN16, PN25, etc.).

- Slip-on flanges to EN 1092-1 are commonly used in European piping systems.

2.5. JIS (Japan)

- JIS B2220 covers slip-on flanges designed for Japanese and some Asian piping systems with nominal size ranges and pressure classes.

2.6. BS (British Standards)

- BS – 1989 specifies dimensions for circular flanges used in British piping systems for valves, fittings, and process lines. While this standard is still referenced today, it has been superseded by EN 1092-1 since 2002 by the British Standards Institution.

3. Specifications of Slip-On Flanges

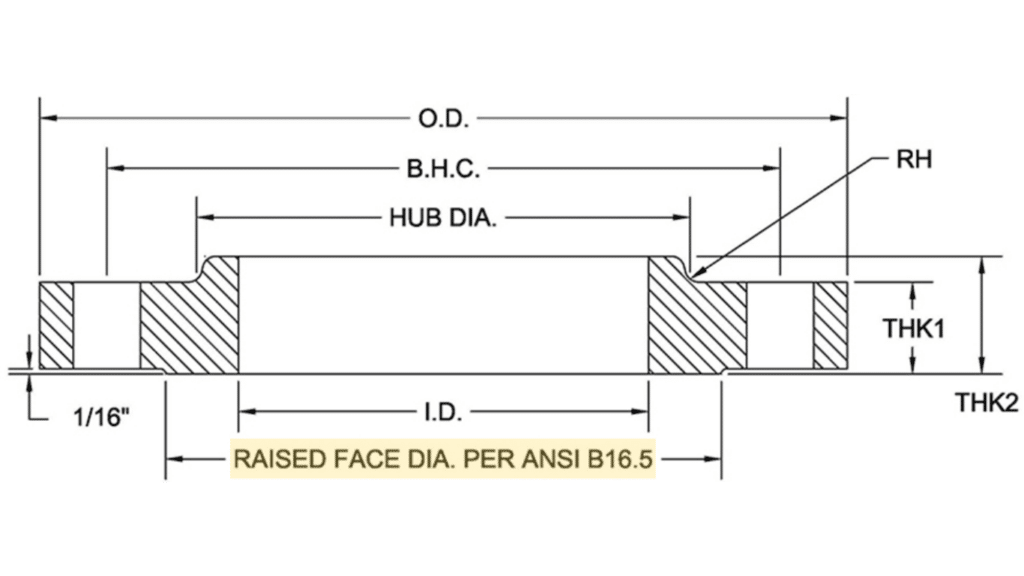

3.1. Design & Dimensions

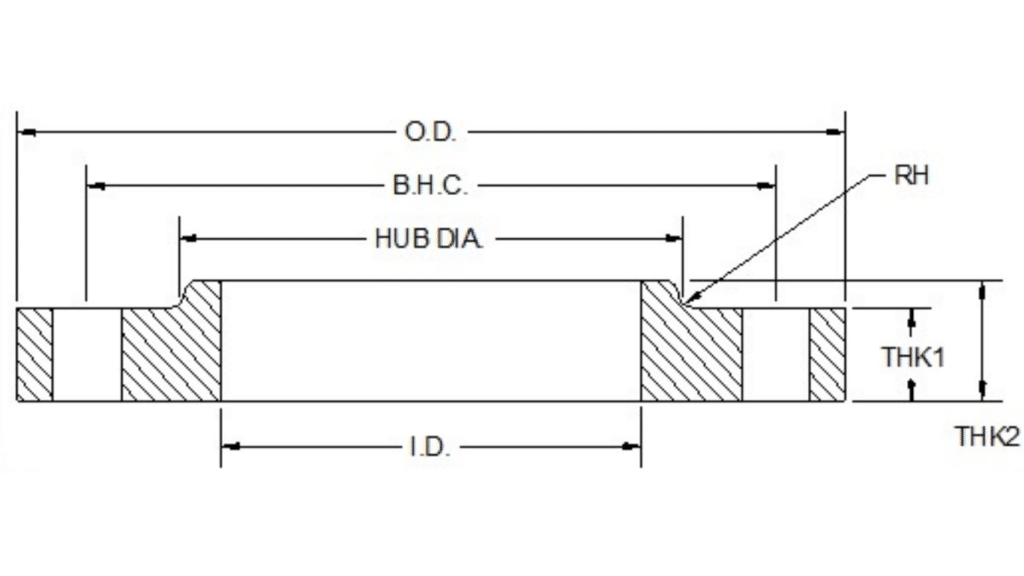

- Bore: ID is slightly larger than pipe OD to allow insertion and alignment before welding.

- Facing: Raised Face (RF), Flat Face (FF), or Ring‑Type Joint (RTJ) grooves per standard.

- Drilling pattern: Bolt circle diameter (BCD), number/size of bolt holes, and spotface per standard; matched to gasket type/class.

- Thickness & hub: Body thickness and hub outside diameter sized by the governing dimensional tables for the pressure class.

The flanges are also manufactured to standard outside diameters, thicknesses, bolt circle diameters, number of bolt holes, etc., usually as per the relevant flange standard.

Example Table — ASME B16.5, Class 150 Slip-On

| NPS | Outside Diameter (in) | Bore I.D. (in) | Flange Thickness (in) | Bolt Hole Circumference (in) | No. of Bolt Holes |

|---|---|---|---|---|---|

| 2 | 6.00 | 2.44 | 0.75 | 4.75 | 4 |

| 4 | 9.00 | 4.57 | 0.88 | 7.50 | 8 |

| 8 | 13.50 | 8.72 | 1.06 | 11.75 | 8 |

| 12 | 19.00 | 12.88 | 1.19 | 17.00 | 12 |

3.2. Pressure Classes of Slip-On Flanges

Slip-on flanges are manufactured to the same pressure classes as other flange types, defined by the governing standard. Under ASME B16.5, slip-on flanges are available in Classes 150, 300, 400, 600, 900, 1500, and 2500, with allowable working pressures that vary by material and temperature.

For waterworks, AWWA C207/C228 specifies slip-on flanges in Classes A, B, D, E, and F, with pressure ratings from about 50 psi (Class A) up to 300 psi (Class F) in cold-water service.

3.3. Material Specifications

| Material Type | Typical Specification | Use Cases & Notes |

|---|---|---|

| Carbon Steel (forged) | ASTM A105 | Most common in moderate service conditions |

| Carbon Steel (low temp) | ASTM A36, Q235 | For low temperature service |

| Stainless (austenitic) | ASTM A182 304L, 316L | For corrosion resistance; verify limits under high temperature or chloride environments |

| Alloy (Cr-Mo) | ASTM A350 (Grade LF2, LF6, LF3) | Elevated temperature & pressure service (e.g. in refineries, power plants) |

| Duplex / Super duplex | Duplex 2205 and super duplex 2507 | Higher strength + corrosion resistance; often used when more aggressive service conditions exist |

3.4. Types of Slip‑On Flanges (by face/type)

- Raised Face (RF) SO — Most common; suited to soft gaskets.

- Flat Face (FF) SO — Used with cast iron equipment/soft gaskets to avoid bending from flange‑face mismatch.

- RTJ SO — Less common; used where metal‑to‑metal seal is specified (higher classes/special services).

Figure 1: Raised Face Slip-On Flange (RF SO)

Figure 2: Flat Face Slip-On Flange (FF SO)

3.5. Hub vs Hubless (Ring-type) Slip-On Flanges

Slip-on flanges can be made with a hub (sometimes called a hub ring) or without a hub (hubless ring-type).

- Hubbed slip-on flange: The hub provides additional weld surface, mechanical strength, and helps with alignment during welding.

- Hubless (ring type) slip-on flange: Simpler and cheaper to produce, but with less mechanical strength in some directions.

4. Advantages vs Disadvantages of Slip-on Flanges

Below is a summary of the advantages and disadvantages of slip-on flanges.

| Feature | Advantages | Disadvantages |

|---|---|---|

| Cost & Fabrication | Cheaper to manufacture and install because of the design simplicity | Limited suitability for high-pressure or critical service |

| Ease of Installation | Slides easily over the pipe, simplifying alignment and welding | Requires welding on both inside and outside surfaces |

| Weld Strength | Dual fillet welds provide adequate strength for moderate service conditions | Fillet welds are usually weaker than full-penetration welds under extreme loads |

| Versatility | Available with and without a hub, widely applicable in general piping | Performance decreases in high-temperature or high-pressure environments |

| Maintenance | Can be disassembled and replaced when needed | Weld removal can be more labor-intensive than bolted-only joints |

| Stress Distribution | Performs reliably under moderate mechanical loads | Higher stress concentrations may develop at weld points under severe conditions |

| Corrosion Considerations | Can be protected with coatings or corrosion-resistant materials | Weld areas are more exposed and may be vulnerable to corrosion or fatigue |

5. Applications

Slip-on flanges are used across many different industries, but they are best suited for low- to medium-pressure systems. Below are common applications:

- Municipal Water and Wastewater Systems – Slip-on flanges made to AWWA C207/C228 standards are common in waterworks. They are used for connecting pumps, valves, and piping in treatment plants and distribution networks.

- Industrial Piping Systems – Common in chemical, petrochemical, and refinery plants under ASME B16.5 and B16.47, used for moderate-pressure service lines.

- HVAC and Chilled Water Circuits – Installed in chillers, heat exchangers, and large piping for heating and cooling.

- Fire Protection Systems – Used in sprinkler and hydrant networks that operate at moderate pressures.

- Marine and Offshore Applications – Stainless steel or alloy slip-on flanges are applied in marine water lines and offshore platforms.

- Food, Beverage, and Pharmaceutical Industries – Stainless steel slip-on flanges (ASTM A182 304L/316L) are used in sanitary lines for easy cleaning, maintenance, and frequent assembly/disassembly.

- Irrigation and Agricultural Systems – Used in large-diameter pipelines for irrigation.

In many piping systems, a blind flange (per the same standard class) is used at the end of a piping run, while slip-on flanges are used on intermediate pipe segments. For a more detailed comparison, see our guide on Blind Flange vs Slip-On Flange.

| Feature | Blind Flange | Slip-On Flange |

|---|---|---|

| Purpose | Used to terminate (cap) a pipeline or open flange | Used to connect pipe to pipe, or pipe to equipment |

| Bore | No bore (solid) | Has a bore/slip fit over pipe |

| Weld requirement | Blind flanges are not usually welded (they are bolted to the mating flange already attached on the pipe). | Welded via fillet welds (inside and outside) |

| Strength | High structural strength to block pressure | Moderate strength; dependent on welds and flange body |

| Ease of removal | Can be removed (with bolts) for opening line | Removable similarly when bolted connections are used |

| Cost | Sometimes more expensive (solid forging) | Generally more economical for through connections |

7. Slip-On Flange vs Weld-Neck Flange

Slip-on flanges are economical and simple to install, while weld-neck flanges are designed for strength and reliability in demanding conditions. For a deeper technical comparison, see our Slip-On Flange vs Weld-Neck Flange overview.

| Feature | Slip-On Flange | Weld-Neck Flange |

|---|---|---|

| Geometry | Slips over pipe and is fillet-welded | Pipe is inserted into flange hub and fully butt-welded |

| Weld type | Fillet welds (inside + outside) | Full-penetration butt weld (often with backing, radiographic test) |

| Stress handling | Adequate for moderate stresses | Superior for high pressure, bending, cyclic loads |

| Fabrication cost | Typically less costly and easier to machine | More expensive due to thicker hub, weld prep, QC |

| Alignment & installation | Easier to align; some angular tolerance | More demanding in alignment, welding precision |

| Suitability | Best for moderate pressure, non-critical lines | Preferred for high pressure, high temperature or critical lines |

8. Conclusion

Slip-on flanges provide a solid option for many moderate-duty piping systems, yet they are not suitable for extremely high-stress or high-pressure systems. Our sales team at API can answer any questions about your flange requirements. Depending on its application, they can also recommend alternative products that may be better suited for your system. We also provide custom flange solutions tailored to your project specifications. Get connected with a dedicated sales representative today! Or call us: 503.692.3800