Carbon steel flanges are produced from a variety of steel options containing anywhere from 0.05% to 2.1% carbon, which directly affects the strength, hardness, ductility, and weldability. The chemical composition of carbon steel (with the absense of chromium, nickel, molybdenum, and other elements) makes it both cost-effective and versatile.

One of the advantages of carbon steel is that it can be easily machined, welded, and heat treated, which allows manufacturers to tailor flanges for a wide range of applications. As the carbon content increases, the steel can be made stronger and harder, though this also reduces ductility and weldability. Grades like ASTM A36 (mild/low carbon steel plate flange) and A105 (medium carbon, forged flanges) are most common in industrial piping systems.

ASTM A105 – The most common grade used for forged carbon steel flanges in ambient and high-temperature pressure systems.

ASTM A36 / Q235 – Designed for low-temperature applications with enhanced toughness.

ASTM A694 (F42–F70) – A stronger-grade material commonly used in high-pressure oil and gas systems.

ANSI/ASME B16.5 – Applies to pipe flanges from ½″ to 24″, offering pressure classes 150, 300, 400, 600, 900, 1500, and 2500. The standard defines flange dimensions, pressure-temperature ratings, and tolerance limits, and includes materials like ASTM A105.

ANSI/ASME B16.47 – Covers larger weld-neck and blind flanges (26″ to 60″), divided into Series A and B, with pressure classes 75, 150, 300, 400, 600, and 900.

AWWA C207 – Covers carbon steel flanges used in waterworks and other applications up to 300 psi.

| Type | Common Grades | Carbon Content | Notes |

|---|---|---|---|

| Mild / Low Carbon Steel | ASTM A36, Q235 | 0.05–0.30% | Most widely used. Good machinability, ductility, and weldability. |

| Medium Carbon Steel | ASTM A105 | 0.30–0.50% | Stronger than mild steel, used in forged flanges and pressure applications. |

| High Carbon Steel | AISI/SAE 1060–1095 series | 0.60–1.00% | Very strong and hard, but less ductile. Materials are not recommended for flanges. |

| Ultra-High Carbon Steel | W1 and T10 | 1.00–2.00% | Extremely hard and brittle. Materials are not recommended for flanges; they are more common in specialized tooling. |

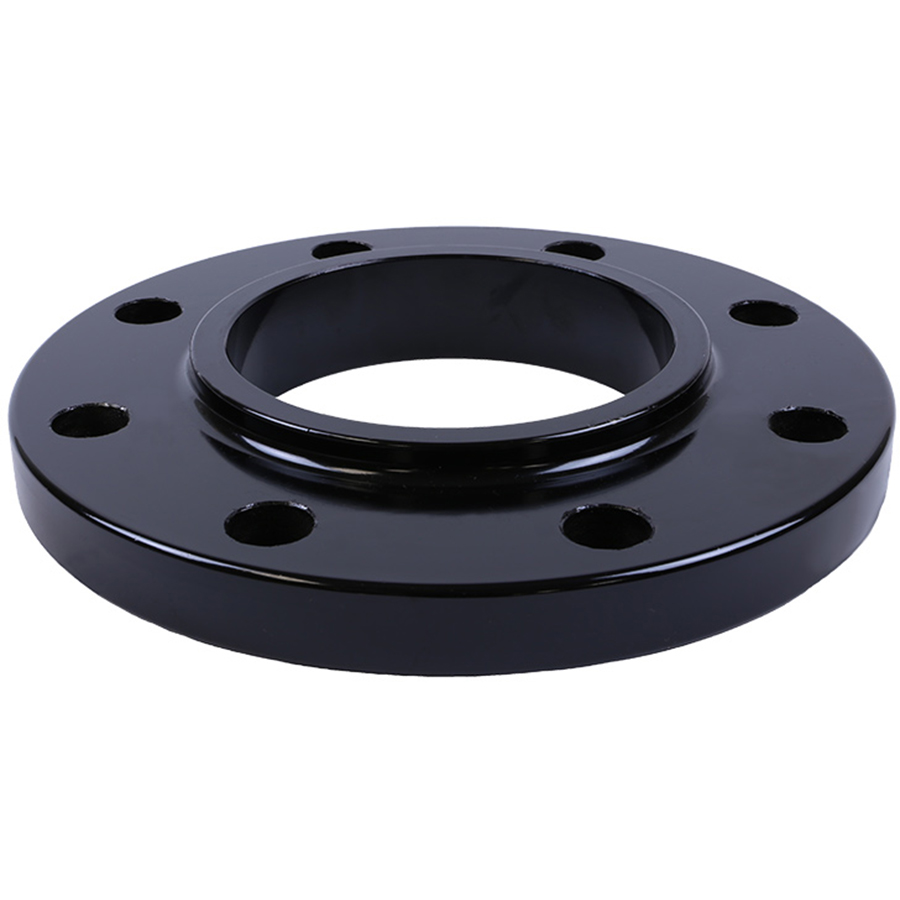

Carbon steel plate flanges are cut from steel plate and then machined to size. They are cost-effective, widely available, and suitable for lower-pressure applications where extreme strength is not critical. Common uses include waterworks, light industrial piping, and systems requiring quick fabrication.

Carbon steel forged flanges are manufactured through forging, the process which improves grain structure and mechanical strength of flanges. Forged carbon steel flanges have higher durability, resistance to impact, and ability to withstand higher pressures and temperatures compared to plate flanges.

Carbon steel flanges provide secure, leak-proof connections in high-pressure liquid transport systems, which makes them essential for petroleum and natural gas infrastructure.

Used in steam lines, heat exchangers, and other high-temperature systems.

Resistant to harsh operating conditions, carbon steel flanges are well-suited for handling various chemicals and process fluids.

Commonly applied in pipeline systems for large-scale projects such as buildings, roadways, and manufacturing facilities.

Large-diameter pipelines in treatment plants rely on carbon steel flanges for long-lasting performance and efficient fluid control under demanding conditions.

Carbon steel flanges are pipe connection components made from steel with 0.05–2.1% carbon content. They provide strong, durable, and economical joints in industrial piping systems. They are commonly used in oil and gas, power, chemical, construction, and water treatment applications.

The main difference is corrosion resistance. Stainless steels contain additional elements including chromium, which forms a protective oxide layer that resists rust and chemical attack, making it ideal for corrosive or sanitary environments. Carbon steel, while stronger and more economical, is more prone to rust and usually requires protective coatings for long-term usage.

Common grades for carbon steel flanges include ASTM A105 (forged carbon steel, used in high-temperature services) and ASTM A36 (low-temperature mid/low carbon steel). These grades ensure the flanges can handle specific pressure, temperature, and environmental conditions.

The main difference is corrosion resistance. Stainless steels contain additional elements, including chromium, which forms a protective oxide layer that resists rust and chemical attack, making it ideal for corrosive or sanitary environments. Carbon steel, while stronger and more economical, is more prone to rust and usually requires protective coatings for long-term usage.

To order CS flanges from API International, determine your required pipe size, pressure class, material, and any special standards (such as ANSI/ASME B16.5, or thread style). Contact API International’s experienced team and we will help you select the right flange for your application.

• Custom Bolt Holes, Overbore, Counterbore, Tapped, Welds, O-ring Grooves, Threads, Special Serrations, Bevels, Chamfers

• Metric Parallel, Metric Tapered, Parallel (BSPP), Taper Thread (BSPT), UN/UNF/UNC Thread, NPT (National Pipe Thread)

• MWD

• Contact API’s engineering department for exact specifications and tolerances.

Plastic: Delrin, POM, Lexan, Nylon 66, Nylon 6, PEEK, PP, PE, Acetal

Rubber: EPDM, Neoprene, Buna-N, Viton

Aluminum: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

Copper: 3600, 3604, 3771

Titanium: 1-28

Steel Series:

• Ductile Iron: ASTM A536

• Carbon/Mild Steel: A105, A36, A516-70, A572-50, etc.

• Stainless Steel:

- 300 Series – 303, 304, 304L, 316, 316L

- 400 Series – 420J2, 430, 434, 442

Special Metals: Hastelloy, Inconel, Incoloy, Duplex 2205, Super Duplex 2507, Chrome Steel, alloys, or their equivalents

Stock Finish, Spiral Serrated (Phonographic), Concentric Serrated, Smooth Finish, Cold Water Finish, MWD, Phonographic

Dipped, Nickel Plating, Zinc Plating (clear, yellow, black, red, blue), Super Agitine, Powder, Painted, Galvanized, Epoxy, Lacquer

Water/Wastewater, Irrigation, Agriculture, HVAC, Marine, Exhaust, Mining, Energy/Power Generation/Oil

• Forged:

- Ring Rolling:

• Materials: Carbon Steel, Stainless Steel, Duplex

• Size: 2–202”

• Cast:

- Centrifugal Casting (Industrial):

• Material: Stainless Steel

- Continuous Casting:

• Material: Stainless Steel

- Sand Casting:

• Material: A536, Stainless Steel, Ductile Iron

- Investment/Lost-Wax/Precision Casting

• Material: Stainless Steel

Machining: Milling, Turning, Facing, Boring, Drilling, Tapping, Counter Sinking, Laser Cutting, Water Jet, Plasma Cutting

| Products | Type | Materials | Size Range |

|---|---|---|---|

| Flanges | Flat-Face, Raised-Face, & Plate: Slip-On/Ring Weld, Neck, Blind, Socket Weld, Orifice, Reducing, Threaded | See Materials List | 5–202″ |

| Gaskets | Molded, Extruded, sheet | EPDM, Buna-N, NBR, Non-Asbestos (GNA), Red Rubber (GRR), Viton | 5–60″ |

| Screens For Filters | Basket Screens and Cone Screens (Perforated, Mesh) | Galv. Carbon Steel, Carbon Steel, Stainless Steel | 6”D x 8’-H |

| Rings | Exhaust Rings (Marmon Flanges for DPF Filters) | Carbon Steel, Stainless Steel, Aluminum | 1–16” |

| Seamless Rolled Rings | Forged | Carbon Steel, Stainless Steel, Aluminum | 1–165” |

| Square Hole Rings | Repair Couplers | Carbon Steel, Stainless Steel, Galvanized, Epoxy Coated | 3–32” |

| Fabricated Assemblies | Weldments, Pipe Spools, Valve Bodies, Silencer Housings | Carbon Steel, Stainless Steel | 2–24” |

| Long/Short Radius Elbows | EN 10253-2–S235, P235GH–P265GH–P265NL and ASTM A234, WPB, WPC/ A420 WPL6, WPL3/ A860 WPHY52/ ASTM A234 WP11, WP22, WP5, WP9–16Mo3 | 304L & 316L Stainless Steel | (45° & 90°): OD: 21.3mm (1/2”)–3048mm (120”) WT: Up to SCH. XXS/160 |

| Miscellaneous | Tubesheets / Diffuser Plates / Baffles / Ferrules / Sleeves / Pins | Carbon Steel, Stainless Steel, Duplex | 5–104” |

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews