Lightweight plate flanges are specialized pipe flanges that were engineered for low-pressure systems where the use of full-weight, pressure-rated fittings is unnecessary. Typically, they are made from carbon or stainless steel plate and designed to minimize material use and reduce overall system weight, which makes them ideal for irrigation and large-diameter piping, along with structural supports and utility lines. Their simplified geometry allows for quicker bolt-up and easier handling during installation, which is especially needed in field conditions or projects with limited lifting capacity.

Lightweight flanges are manufactured to AWWA C207 material standards and ANSI Class 150 bolt pattern specifications.

Standard flange thicknesses for lightweight applications are typically ½ inch or ⅝ inch, which provides sufficient strength while minimizing overall weight. Additional thicknesses and material grades may be used depending on application requirements.

Lightweight steel plate flanges are manufactured according to AWWA C207 material specifications, which define the required steel quality and thickness for waterworks and structural piping systems.

Blind and slip-on flanges follow the ANSI Class 150 bolt pattern, which defines the bolt hole layout and dimensions for consistent fit across low- to moderate-pressure piping systems.

They are used to connect pipes in low-pressure applications, such as pumping stations, distribution lines, and sprinkler systems. Their simple design and reduced weight make them cost-effective and easy to install in agricultural and municipal water networks.

Compact design and lighter weight help reduce stress on exhaust manifolds while still providing a reliable seal for high-temperature gases.

They are commonly found in heating, ventilation, and air conditioning systems for providing efficient heat management.

These flanges are perfect for where lower weight eases handling during assembly and maintenance.

Ideal for shipbuilding and offshore equipment because they resist corrosion and reduce load on structures.

Used in wind turbines and solar power piping for lightweight and tight connections.

Used in aircraft engine components, airframes, and fuel systems.

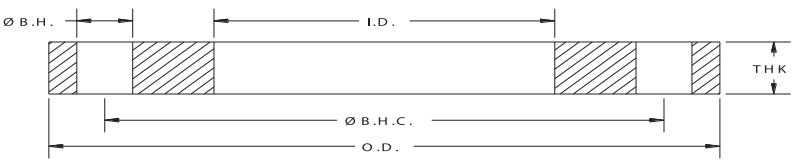

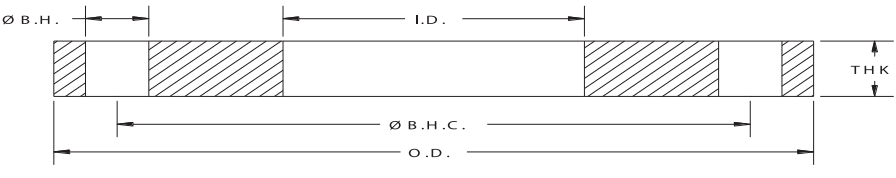

Used for joining pipes by slipping over the pipe end and welding in place. These flanges have a flat face and are commonly used in low-pressure systems with soft gasket materials.

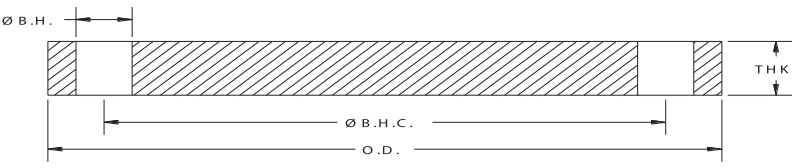

Solid disks without a center opening, used to close off pipe ends or openings. Blind flanges allow pressure testing and system isolation without permanent pipe removal.

Lightweight flanges are specially engineered flanges made from lighter materials or with reduced profiles to ease installation and reduce structural load while maintaining pressure integrity.

Lightweight flanges are designed to reduce mass while providing similar functionality. They typically use thinner profiles or lighter alloys compared to standard flanges, which are bulkier and heavier.

Lightweight Plate Flange Class Designation” refers to either low-pressure closed systems, or open-ended systems where pressure thrust values are low.

Easier handling and installation

Lower shipping and structural costs

Suitable for Irrigation, Diesel/Generator Exhaust, aerospace, marine, HVAC, and all other low pressure systems

• Custom Bolt Holes, Overbore, Counterbore, Tapped, Welds, O-ring Grooves, Threads, Special Serrations, Bevels, Chamfers

• Metric Parallel, Metric Tapered, Parallel (BSPP), Taper Thread (BSPT), UN/UNF/UNC Thread, NPT (National Pipe Thread)

• MWD

• Contact API’s engineering department for exact specifications and tolerances.

Plastic: Delrin, POM, Lexan, Nylon 66, Nylon 6, PEEK, PP, PE, Acetal

Rubber: EPDM, Neoprene, Buna-N, Viton

Aluminum: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

Copper: 3600, 3604, 3771

Titanium: 1-28

Steel Series:

• Ductile Iron: ASTM A536

• Carbon/Mild Steel: A105, A36, A516-70, A572-50, etc.

• Stainless Steel:

- 300 Series – 303, 304, 304L, 316, 316L

- 400 Series – 420J2, 430, 434, 442

Special Metals: Hastelloy, Inconel, Incoloy, Duplex 2205, Super Duplex 2507, Chrome Steel, alloys, or their equivalents

Stock Finish, Spiral Serrated (Phonographic), Concentric Serrated, Smooth Finish, Cold Water Finish, MWD, Phonographic

Dipped, Nickel Plating, Zinc Plating (clear, yellow, black, red, blue), Super Agitine, Powder, Painted, Galvanized, Epoxy, Lacquer

Water/Wastewater, Irrigation, Agriculture, HVAC, Marine, Exhaust, Mining, Energy/Power Generation/Oil

• Forged:

- Ring Rolling:

• Materials: Carbon Steel, Stainless Steel, Duplex

• Size: 2–202”

• Cast:

- Centrifugal Casting (Industrial):

• Material: Stainless Steel

- Continuous Casting:

• Material: Stainless Steel

- Sand Casting:

• Material: A536, Stainless Steel, Ductile Iron

- Investment/Lost-Wax/Precision Casting

• Material: Stainless Steel

Machining: Milling, Turning, Facing, Boring, Drilling, Tapping, Counter Sinking, Laser Cutting, Water Jet, Plasma Cutting

| Products | Type | Materials | Size Range |

|---|---|---|---|

| Flanges | Flat-Face, Raised-Face, & Plate: Slip-On/Ring Weld, Neck, Blind, Socket Weld, Orifice, Reducing, Threaded | See Materials List | 5–202″ |

| Gaskets | Molded, Extruded, sheet | EPDM, Buna-N, NBR, Non-Asbestos (GNA), Red Rubber (GRR), Viton | 5–60″ |

| Screens For Filters | Basket Screens and Cone Screens (Perforated, Mesh) | Galv. Carbon Steel, Carbon Steel, Stainless Steel | 6”D x 8’-H |

| Rings | Exhaust Rings (Marmon Flanges for DPF Filters) | Carbon Steel, Stainless Steel, Aluminum | 1–16” |

| Seamless Rolled Rings | Forged | Carbon Steel, Stainless Steel, Aluminum | 1–165” |

| Square Hole Rings | Repair Couplers | Carbon Steel, Stainless Steel, Galvanized, Epoxy Coated | 3–32” |

| Fabricated Assemblies | Weldments, Pipe Spools, Valve Bodies, Silencer Housings | Carbon Steel, Stainless Steel | 2–24” |

| Long/Short Radius Elbows | EN 10253-2–S235, P235GH–P265GH–P265NL and ASTM A234, WPB, WPC/ A420 WPL6, WPL3/ A860 WPHY52/ ASTM A234 WP11, WP22, WP5, WP9–16Mo3 | 304L & 316L Stainless Steel | (45° & 90°): OD: 21.3mm (1/2”)–3048mm (120”) WT: Up to SCH. XXS/160 |

| Miscellaneous | Tubesheets / Diffuser Plates / Baffles / Ferrules / Sleeves / Pins | Carbon Steel, Stainless Steel, Duplex | 5–104” |

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews