Overbore flanges are designed with a bore diameter larger than the standard pipe size, allowing for custom piping configurations where unique flow, pressure, or mechanical requirements are involved. They’re commonly used in applications where the pipe size or OD differs from the flange bore, ensuring proper fit and reliable performance.

An overbore flange features an inner diameter (ID) significantly larger than what standard pipe flanges offer. This allows it to bridge mismatched or oversized piping—or adapt to complex pipe configurations—without requiring reducers or extensive rework.

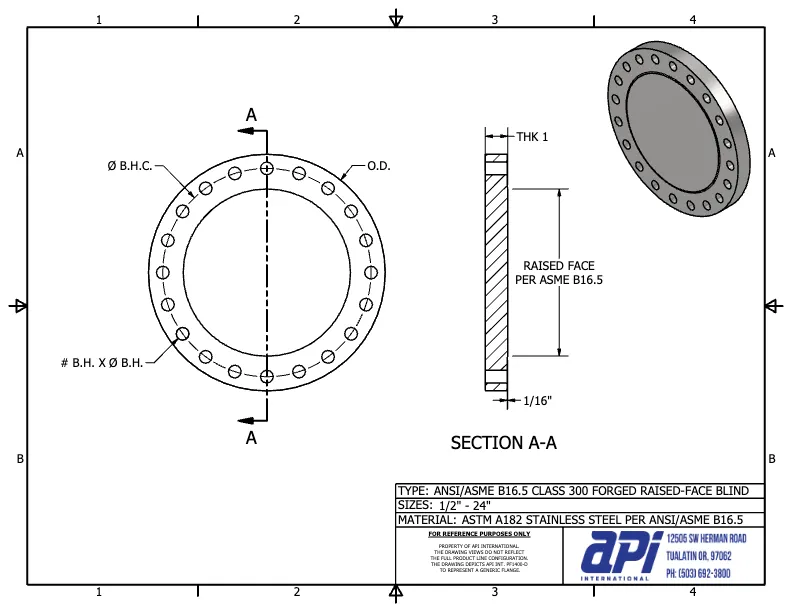

These flanges are fully machined and commonly made from materials like ASTM A36 mild steel, ASTM A105, C207‑13, or Q235. Many are categorized under AWWA C207 Standards for Class 150 or Class 300 drilling options (denoted as Class B, D, E, F), and ANSI/ASME B16.5, ensuring they meet established water and industrial standards.

You’ll find a wide range of sizes, including IDs like 14.75″, 16.75″, 18.75″, up to 56.00″, each paired with corresponding outer diameters (OD), thicknesses, bolt hole counts, and bolt hole circles (BHC)—designed for seamless fit and installation.

| Class | Inner Diameter (I.D.) Range | Outer Diameter (O.D.) Range | Thickness Range | Bolt Count Range |

|---|---|---|---|---|

| D | 14″ – 20″ | 21″ – 27.5″ | 0.9″ – 1.25″ | 12 – 20 bolts |

| D | 24″ – 36″ | 32″ – 44.5″ | 1.0″ – 1.5″ | 20 – 28 bolts |

| D | 40″ – 56″ | 48″ – 66″ | 1.25″ – 2.1″ | 32 – 44 bolts |

| E | 16″ – 24″ | 23″ – 32″ | 2.0″ – 2.6″ | 16 – 20 bolts |

| E | 30″ – 42″ | 38″ – 53″ | 2.6″ – 3.2″ | 20 – 36 bolts |

| E/F | 48″ – 60″+ | 59″ – 87″+ | 3.2″ – 4.5″ | 36 – 44 bolts |

AWWA standards set clear guidelines for overbore flange dimensions, materials, and production and ensure reliable connections and leak-free performance.

ANSI/ASME B16.5 and B16.47 standards cover flange dimensions, pressure classes, and materials, ensuring compatibility across a wide range of piping systems.

DIN flanges offer metric dimensions, bolt patterns, and pressure ratings for reliable connections in piping systems and industrial applications.

These flanges allow engineers to circumvent the need for extra reducers or custom-fabricated transitions when piping dimensions vary or are nonstandard.

Because many overbore flanges come as pre-machined, standardized plates, you can often find what you need in inventory, which shortens lead times and cuts fabrication costs.

With AWWA Class 150 categorization and compatibility with ASTM materials, overbore flanges are particularly suited for water infrastructure and industrial systems relying on uniform standards.

A flange machined with an enlarged internal bore to fit oversized pipe or special inserts while keeping outer dimensions and bolt patterns unchanged.

To order overbore flanges from API International, determine your required pipe size, pressure class, material, and any special standards. Contact API International’s experienced team, who will help you select the right flange for your application.

• Custom Bolt Holes, Overbore, Counterbore, Tapped, Welds, O-ring Grooves, Threads, Special Serrations, Bevels, Chamfers

• Metric Parallel, Metric Tapered, Parallel (BSPP), Taper Thread (BSPT), UN/UNF/UNC Thread, NPT (National Pipe Thread)

• MWD

• Contact API’s engineering department for exact specifications and tolerances.

Plastic: Delrin, POM, Lexan, Nylon 66, Nylon 6, PEEK, PP, PE, Acetal

Rubber: EPDM, Neoprene, Buna-N, Viton

Aluminum: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

Copper: 3600, 3604, 3771

Titanium: 1-28

Steel Series:

• Ductile Iron: ASTM A536

• Carbon/Mild Steel: A105, A36, A516-70, A572-50, etc.

• Stainless Steel:

- 300 Series – 303, 304, 304L, 316, 316L

- 400 Series – 420J2, 430, 434, 442

Special Metals: Hastelloy, Inconel, Incoloy, Duplex 2205, Super Duplex 2507, Chrome Steel, alloys, or their equivalents

Stock Finish, Spiral Serrated (Phonographic), Concentric Serrated, Smooth Finish, Cold Water Finish, MWD, Phonographic

Dipped, Nickel Plating, Zinc Plating (clear, yellow, black, red, blue), Super Agitine, Powder, Painted, Galvanized, Epoxy, Lacquer

Water/Wastewater, Irrigation, Agriculture, HVAC, Marine, Exhaust, Mining, Energy/Power Generation/Oil

• Forged:

- Ring Rolling:

• Materials: Carbon Steel, Stainless Steel, Duplex

• Size: 2–202”

• Cast:

- Centrifugal Casting (Industrial):

• Material: Stainless Steel

- Continuous Casting:

• Material: Stainless Steel

- Sand Casting:

• Material: A536, Stainless Steel, Ductile Iron

- Investment/Lost-Wax/Precision Casting

• Material: Stainless Steel

Machining: Milling, Turning, Facing, Boring, Drilling, Tapping, Counter Sinking, Laser Cutting, Water Jet, Plasma Cutting

| Products | Type | Materials | Size Range |

|---|---|---|---|

| Flanges | Flat-Face, Raised-Face, & Plate: Slip-On/Ring Weld, Neck, Blind, Socket Weld, Orifice, Reducing, Threaded | See Materials List | 5–202″ |

| Gaskets | Molded, Extruded, sheet | EPDM, Buna-N, NBR, Non-Asbestos (GNA), Red Rubber (GRR), Viton | 5–60″ |

| Screens For Filters | Basket Screens and Cone Screens (Perforated, Mesh) | Galv. Carbon Steel, Carbon Steel, Stainless Steel | 6”D x 8’-H |

| Rings | Exhaust Rings (Marmon Flanges for DPF Filters) | Carbon Steel, Stainless Steel, Aluminum | 1–16” |

| Seamless Rolled Rings | Forged | Carbon Steel, Stainless Steel, Aluminum | 1–165” |

| Square Hole Rings | Repair Couplers | Carbon Steel, Stainless Steel, Galvanized, Epoxy Coated | 3–32” |

| Fabricated Assemblies | Weldments, Pipe Spools, Valve Bodies, Silencer Housings | Carbon Steel, Stainless Steel | 2–24” |

| Long/Short Radius Elbows | EN 10253-2–S235, P235GH–P265GH–P265NL and ASTM A234, WPB, WPC/ A420 WPL6, WPL3/ A860 WPHY52/ ASTM A234 WP11, WP22, WP5, WP9–16Mo3 | 304L & 316L Stainless Steel | (45° & 90°): OD: 21.3mm (1/2”)–3048mm (120”) WT: Up to SCH. XXS/160 |

| Miscellaneous | Tubesheets / Diffuser Plates / Baffles / Ferrules / Sleeves / Pins | Carbon Steel, Stainless Steel, Duplex | 5–104” |

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews