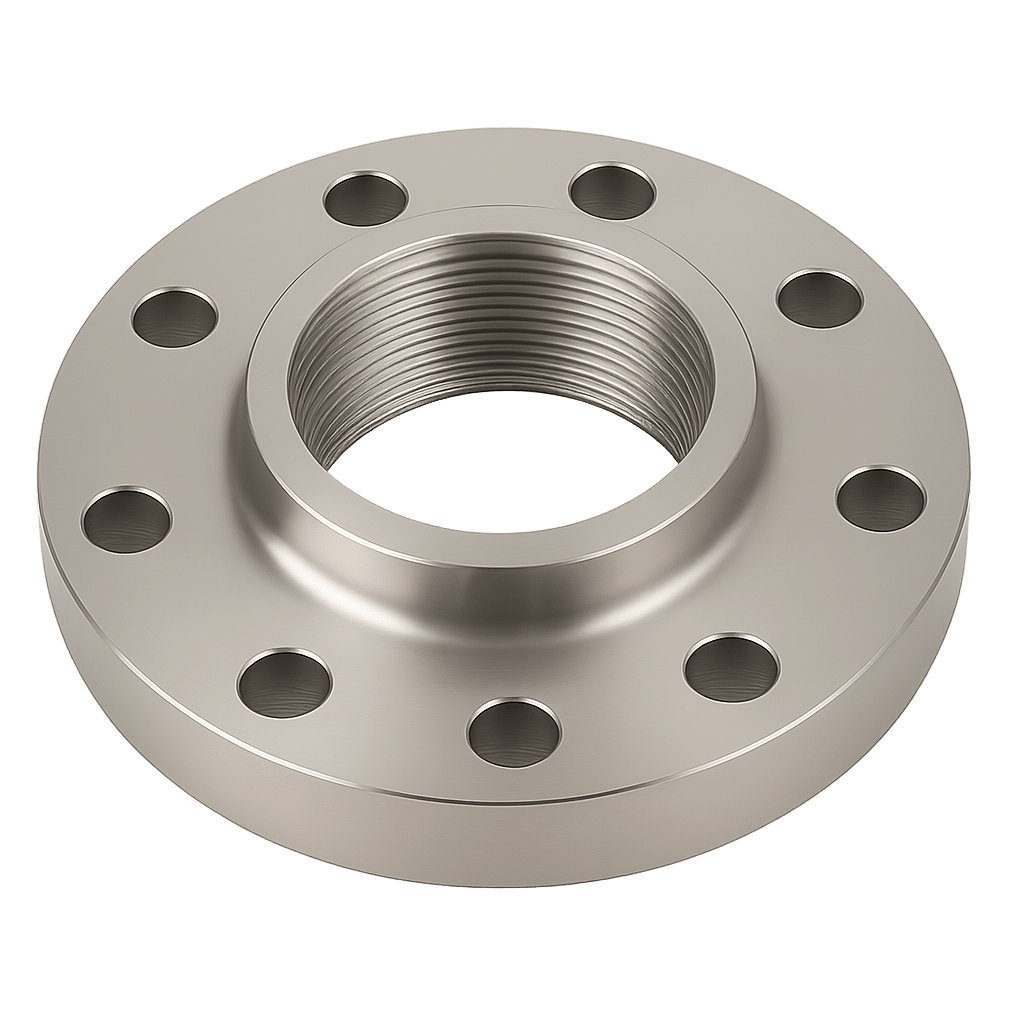

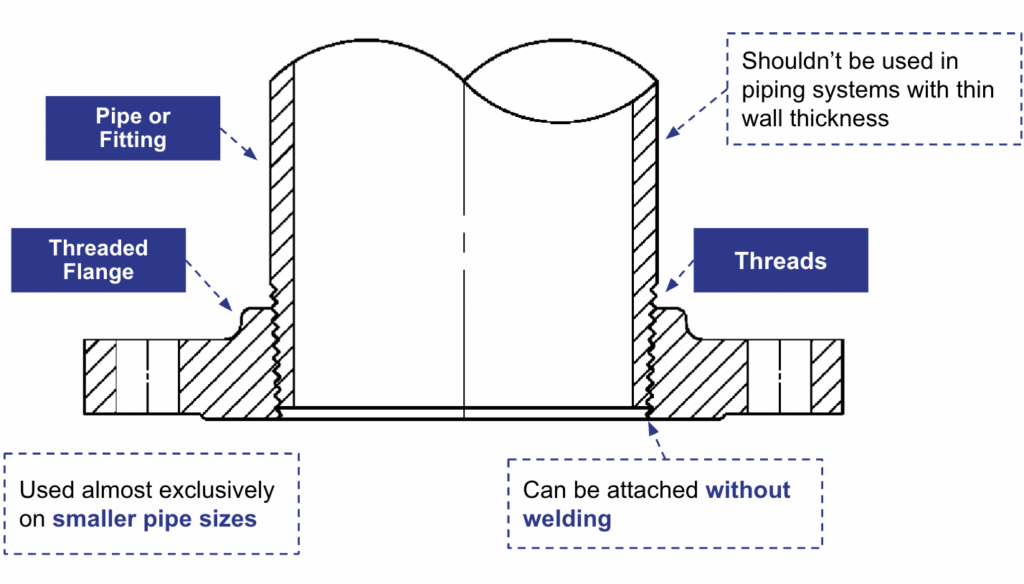

Threaded flanges are a type of pipe fitting that connects to a pipe using screw threads instead of welding. The flange has a hole in the center with internal threads, and it fits onto a pipe that has matching external threads. This allows for a tight and secure connection without the need for welding equipment or high-heat processes. Because of this simple process, installation is usually quick and straightforward, which makes these flanges a convenient choice for many basic piping systems.

These flanges are commonly used in piping systems for water, air, oil, or gas transportation under moderate pressure and temperature conditions. They are especially useful in environments where welding is not safe or practical, such as areas with flammable gases or liquids. Threaded flanges also make maintenance easier, as they can be removed and reattached without damaging the pipe.

Threaded flanges are manufactured according to ANSI/ASME B16.5, which defines the dimensional, material, and pressure requirements for pipe flanges and fittings up to NPS 24. This standard ensures compatibility across systems and guarantees a safe connection for flanged joints.

Threaded flanges shall have a taper pipe thread conforming to ASME B1.20.1. ASME B1.20.1 is the American National Standard for General Purpose Pipe Threads, specifically covering inch-based threads. It defines the dimensional and gaging requirements for:

NPT (National Pipe Taper)

NPSC (National Pipe Straight Coupling)

NPTR (National Pipe Taper Railing)

NPSM (National Pipe Straight Mechanical)

NPSL (National Pipe Straight Loose)

Threaded Flanges have a taper conforming to ASME B1.20.1 and concentric with the flange opening to 5 mm/m.

Class 300 and Higher

The following table shows dimensional ranges for ASME B16.5 threaded flanges from ½″ to 24″ nominal pipe size (NPS).

| NPS Range | Outside Diameter (OD) | Bore Diameter (A) | Flange Thickness (B) |

|---|---|---|---|

| ½″ – 2″ | 3.5″ – 6.0″ | 0.62″ – 2.07″ | 0.44″ – 0.82″ |

| 2½″ – 6″ | 7.0″ – 11.0″ | 2.47″ – 6.07″ | 0.88″ – 1.19″ |

| 8″ – 12″ | 13.5″ – 19.0″ | 8.07″ – 12.11″ | 1.31″ – 1.44″ |

| 14″ – 20″ | 21.0″ – 27.5″ | 14.13″ – 20.15″ | 1.62″ – 2.00″ |

| 24″ | 32.0″ | 24.15″ | 2.25″ |

Ideal in explosive environments where welding is prohibited, such as fuel depots or gas plants.

Used in test setups or systems that require frequent disassembly and reassembly.

Suitable for general plumbing and utility piping where pressure is minimal.

Often found in sprinkler systems because of the simple maintenance.

The entire face is flat and flush with the gasket surface. Used where space or flexibility is limited, typically in low-pressure applications.

Includes a raised sealing surface around the bore to improve gasket compression and leak resistance under moderate pressure.

Threaded flanges (also called screwed flanges) feature internal threads that allow them to be screwed directly onto the external threads of a pipe. This design enables a secure, non-welded connection and makes them ideal for systems where welding isn’t feasible or safe.

Threaded flanges are better suited for low-pressure systems and are easier to install without welding. In contrast, slip-on flanges require welding and are typically used in higher-pressure applications where additional strength is needed.

Threaded flanges are ideal for low-pressure, non-critical piping systems, especially where welding is unsafe or impractical. They’re also convenient for temporary setups or systems needing frequent disassembly.

Prepare the pipeline and clean threads.

Apply a thread sealant or Teflon tape.

Screw the flange onto the pipe until snug.

Use a wrench to tighten as needed.

Align flanges for gasket seating.

Insert gasket.

Install bolts evenly.

Perform a final torque check.

To order threaded flanges from API International, determine your required pipe size, pressure class, material, threaded connection, and any special standards (such as ANSI/ASME B16.5). Contact API International’s experienced team, who will help you select the right flange for your application.

• Custom Bolt Holes, Overbore, Counterbore, Tapped, Welds, O-ring Grooves, Threads, Special Serrations, Bevels, Chamfers

• Metric Parallel, Metric Tapered, Parallel (BSPP), Taper Thread (BSPT), UN/UNF/UNC Thread, NPT (National Pipe Thread)

• MWD

• Contact API’s engineering department for exact specifications and tolerances.

Plastic: Delrin, POM, Lexan, Nylon 66, Nylon 6, PEEK, PP, PE, Acetal

Rubber: EPDM, Neoprene, Buna-N, Viton

Aluminum: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

Copper: 3600, 3604, 3771

Titanium: 1-28

Steel Series:

• Ductile Iron: ASTM A536

• Carbon/Mild Steel: A105, A36, A516-70, A572-50, etc.

• Stainless Steel:

- 300 Series – 303, 304, 304L, 316, 316L

- 400 Series – 420J2, 430, 434, 442

Special Metals: Hastelloy, Inconel, Incoloy, Duplex 2205, Super Duplex 2507, Chrome Steel, alloys, or their equivalents

Stock Finish, Spiral Serrated (Phonographic), Concentric Serrated, Smooth Finish, Cold Water Finish, MWD, Phonographic

Dipped, Nickel Plating, Zinc Plating (clear, yellow, black, red, blue), Super Agitine, Powder, Painted, Galvanized, Epoxy, Lacquer

Water/Wastewater, Irrigation, Agriculture, HVAC, Marine, Exhaust, Mining, Energy/Power Generation/Oil

• Forged:

- Ring Rolling:

• Materials: Carbon Steel, Stainless Steel, Duplex

• Size: 2–202”

• Cast:

- Centrifugal Casting (Industrial):

• Material: Stainless Steel

- Continuous Casting:

• Material: Stainless Steel

- Sand Casting:

• Material: A536, Stainless Steel, Ductile Iron

- Investment/Lost-Wax/Precision Casting

• Material: Stainless Steel

Machining: Milling, Turning, Facing, Boring, Drilling, Tapping, Counter Sinking, Laser Cutting, Water Jet, Plasma Cutting

| Products | Type | Materials | Size Range |

|---|---|---|---|

| Flanges | Flat-Face, Raised-Face, & Plate: Slip-On/Ring Weld, Neck, Blind, Socket Weld, Orifice, Reducing, Threaded | See Materials List | 5–202″ |

| Gaskets | Molded, Extruded, sheet | EPDM, Buna-N, NBR, Non-Asbestos (GNA), Red Rubber (GRR), Viton | 5–60″ |

| Screens For Filters | Basket Screens and Cone Screens (Perforated, Mesh) | Galv. Carbon Steel, Carbon Steel, Stainless Steel | 6”D x 8’-H |

| Rings | Exhaust Rings (Marmon Flanges for DPF Filters) | Carbon Steel, Stainless Steel, Aluminum | 1–16” |

| Seamless Rolled Rings | Forged | Carbon Steel, Stainless Steel, Aluminum | 1–165” |

| Square Hole Rings | Repair Couplers | Carbon Steel, Stainless Steel, Galvanized, Epoxy Coated | 3–32” |

| Fabricated Assemblies | Weldments, Pipe Spools, Valve Bodies, Silencer Housings | Carbon Steel, Stainless Steel | 2–24” |

| Long/Short Radius Elbows | EN 10253-2–S235, P235GH–P265GH–P265NL and ASTM A234, WPB, WPC/ A420 WPL6, WPL3/ A860 WPHY52/ ASTM A234 WP11, WP22, WP5, WP9–16Mo3 | 304L & 316L Stainless Steel | (45° & 90°): OD: 21.3mm (1/2”)–3048mm (120”) WT: Up to SCH. XXS/160 |

| Miscellaneous | Tubesheets / Diffuser Plates / Baffles / Ferrules / Sleeves / Pins | Carbon Steel, Stainless Steel, Duplex | 5–104” |

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews