Our backing flanges can be manufactured to accommodate stub ends and angle face rings. We carry back-up flanges constructed of ductile iron or stainless steel.

Backing flanges are used to reinforce and secure loose flange systems, especially in pipelines where stub ends or face rings are employed. Unlike welded flanges, backing flanges are not bonded to the pipe itself because they slide over the pipe and work in conjunction with other components to create a tight, gasket seal.

These flanges provide mechanical strength for bolted connections and are especially valuable in systems that require frequent maintenance, rotation for alignment, or disassembly. Their design enables cost-effective use of corrosion-resistant materials only at the points in contact with the process fluid, while using more economical materials externally.

Commonly used in water treatment plants, chemical systems, and low- to medium-pressure industrial pipelines. Backing flanges help provide structural reliability and simplified installation without the need for full circumferential welding.

Backing flanges are typically made from ductile iron to ASTM A536 and follow the ANSI Class 150 bolt pattern, with stainless steel options also available. They come in configurations for angle face rings and stub ends.

Offered in painted ductile iron (BF) or hot-dip galvanized ductile iron (GBF), these flanges are built to fit stub ends in piping systems requiring corrosion resistance and strength.

Stainless steel back-up flanges are preferred for their high corrosion resistance.

Galvanized ductile iron combines high strength with enhanced corrosion protection.

A backing flange is a loose ring used in conjunction with stub ends or face rings to create a bolted connection, allowing the pipe to rotate for alignment before tightening.

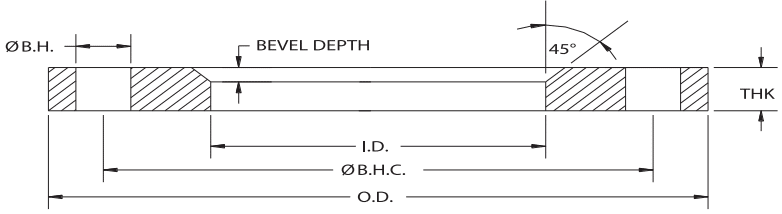

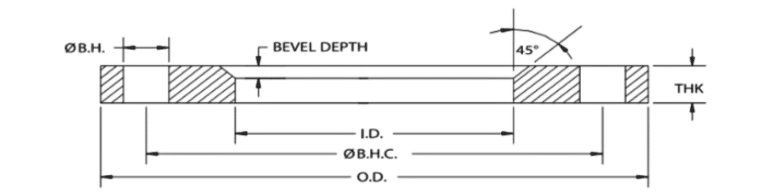

Backing flange dimensions depend on the pipe size, pressure class, and material, but they typically conform to standards such as ANSI B16.5. Sizes range from ½” to 48″ (15NB to 1200NB), with key measurements including the outside diameter (OD), inside diameter (ID), bolt circle diameter (BCD), and bolt hole size.

Backing flanges are common in:

Water treatment plants – for PVC or HDPE pipe systems

Chemical processing – where corrosion-resistant liners are used

Food & beverage – for sanitary stainless steel systems

Mining & slurry transport – paired with abrasion-resistant piping

Marine piping – where alignment flexibility and maintenance access are crucial.

Backing flanges are typically produced from ductile iron and incorporate a bevel/chamfer along the ID, while lap joint flanges are typically forged and machined with a radius along the ID.

Both backing flanges and lap joint flanges are loose components of a lap joint flange assembly, which is a two-part system consisting of a stub end (welded to the pipe) and a separate backing flange that slides over the stub end and bolts to the mating flange.

,The flanges’ primary function is to provide a connection point and allow for easier alignment of bolt holes, as it can be rotated freely while the stub end remains welded to the pipe. The system is more flexible and ideal where disassembly or frequent rotation is needed.

Stainless steel backing flanges are selected for their corrosion resistance, mechanical strength, and long-term reliability in demanding environments. They are ideal for applications involving aggressive chemicals, saltwater exposure, or high humidity. Compared to carbon steel, stainless steel offers reduced maintenance, extended service life, and better performance in hygienic or corrosive settings.

• Custom Bolt Holes, Overbore, Counterbore, Tapped, Welds, O-ring Grooves, Threads, Special Serrations, Bevels, Chamfers

• Metric Parallel, Metric Tapered, Parallel (BSPP), Taper Thread (BSPT), UN/UNF/UNC Thread, NPT (National Pipe Thread)

• MWD

• Contact API’s engineering department for exact specifications and tolerances.

Plastic: Delrin, POM, Lexan, Nylon 66, Nylon 6, PEEK, PP, PE, Acetal

Rubber: EPDM, Neoprene, Buna-N, Viton

Aluminum: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

Copper: 3600, 3604, 3771

Titanium: 1-28

Steel Series:

• Ductile Iron: ASTM A536

• Carbon/Mild Steel: A105, A36, A516-70, A572-50, etc.

• Stainless Steel:

- 300 Series – 303, 304, 304L, 316, 316L

- 400 Series – 420J2, 430, 434, 442

Special Metals: Hastelloy, Inconel, Incoloy, Duplex 2205, Super Duplex 2507, Chrome Steel, alloys, or their equivalents

Stock Finish, Spiral Serrated (Phonographic), Concentric Serrated, Smooth Finish, Cold Water Finish, MWD, Phonographic

Dipped, Nickel Plating, Zinc Plating (clear, yellow, black, red, blue), Super Agitine, Powder, Painted, Galvanized, Epoxy, Lacquer

Water/Wastewater, Irrigation, Agriculture, HVAC, Marine, Exhaust, Mining, Energy/Power Generation/Oil

• Forged:

- Ring Rolling:

• Materials: Carbon Steel, Stainless Steel, Duplex

• Size: 2–202”

• Cast:

- Centrifugal Casting (Industrial):

• Material: Stainless Steel

- Continuous Casting:

• Material: Stainless Steel

- Sand Casting:

• Material: A536, Stainless Steel, Ductile Iron

- Investment/Lost-Wax/Precision Casting

• Material: Stainless Steel

Machining: Milling, Turning, Facing, Boring, Drilling, Tapping, Counter Sinking, Laser Cutting, Water Jet, Plasma Cutting

| Products | Type | Materials | Size Range |

|---|---|---|---|

| Flanges | Flat-Face, Raised-Face, & Plate: Slip-On/Ring Weld, Neck, Blind, Socket Weld, Orifice, Reducing, Threaded | See Materials List | 5–202″ |

| Gaskets | Molded, Extruded, sheet | EPDM, Buna-N, NBR, Non-Asbestos (GNA), Red Rubber (GRR), Viton | 5–60″ |

| Screens For Filters | Basket Screens and Cone Screens (Perforated, Mesh) | Galv. Carbon Steel, Carbon Steel, Stainless Steel | 6”D x 8’-H |

| Rings | Exhaust Rings (Marmon Flanges for DPF Filters) | Carbon Steel, Stainless Steel, Aluminum | 1–16” |

| Seamless Rolled Rings | Forged | Carbon Steel, Stainless Steel, Aluminum | 1–165” |

| Square Hole Rings | Repair Couplers | Carbon Steel, Stainless Steel, Galvanized, Epoxy Coated | 3–32” |

| Fabricated Assemblies | Weldments, Pipe Spools, Valve Bodies, Silencer Housings | Carbon Steel, Stainless Steel | 2–24” |

| Long/Short Radius Elbows | EN 10253-2–S235, P235GH–P265GH–P265NL and ASTM A234, WPB, WPC/ A420 WPL6, WPL3/ A860 WPHY52/ ASTM A234 WP11, WP22, WP5, WP9–16Mo3 | 304L & 316L Stainless Steel | (45° & 90°): OD: 21.3mm (1/2”)–3048mm (120”) WT: Up to SCH. XXS/160 |

| Miscellaneous | Tubesheets / Diffuser Plates / Baffles / Ferrules / Sleeves / Pins | Carbon Steel, Stainless Steel, Duplex | 5–104” |

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews