We begin by understanding your goals, whether it's reducing cost, improving quality, or launching a new product. Together, we define technical and commercial requirements to ensure full alignment from the start.

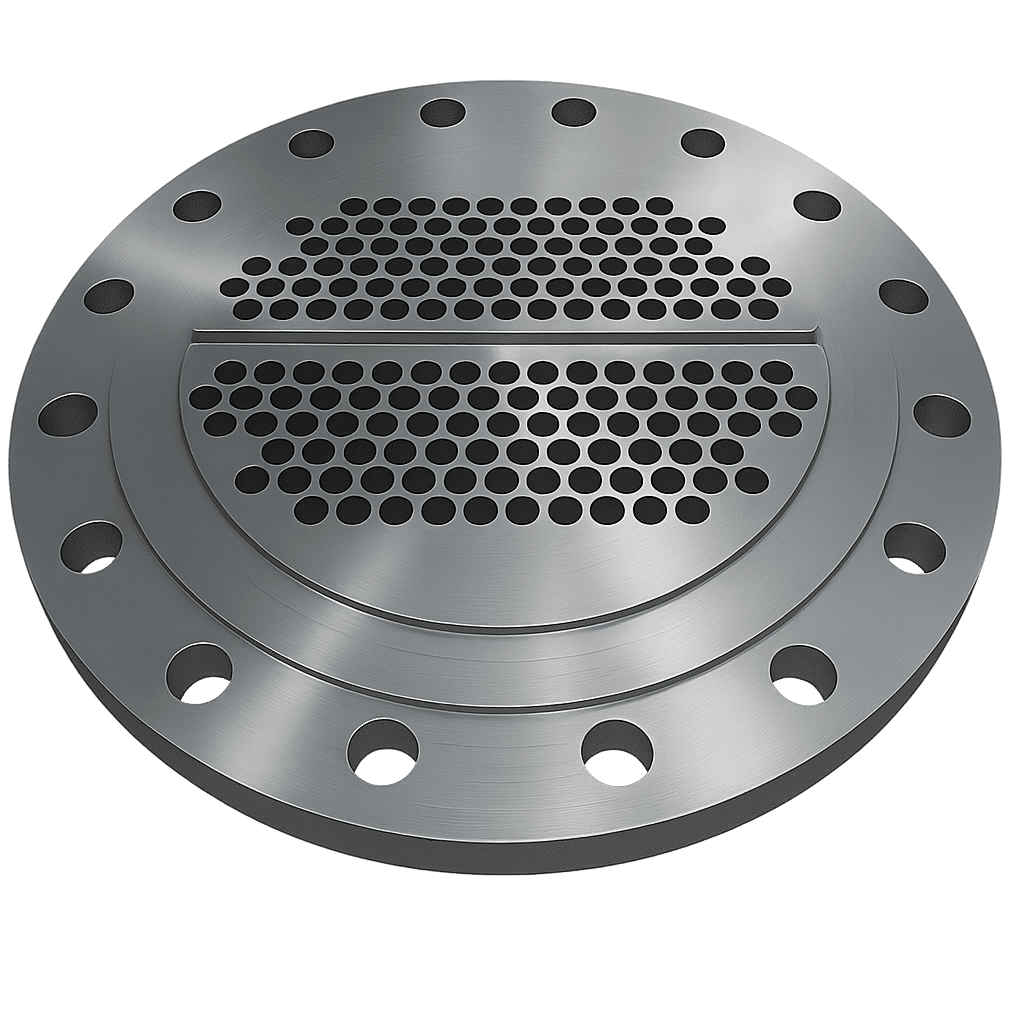

With worldwide manufacturing resources, API International provides both standard and custom flange solutions. Our network of facilities and in-house expertise allow us to deliver the right fit for your needs, whether it’s off-the-shelf or built to specification.

Our engineers work closely with customers to refine designs, reduce costs, and ensure manufacturability. We stay connected with your team throughout to keep progress clear and efficient.

After final review of samples, production begins. Our team oversees quality and delivery coordination to ensure smooth execution and traceability from start to finish.

Mining piping projects typically specify flanges and fittings to recognized dimensional standards so components bolt up correctly and meet pressure/temperature requirements.

Common standards you’ll see include:

It depends on the line’s duty and maintenance needs:

Gasket selection should match the media (slurry chemistry, acids, process water), temperature, and the joint’s mechanical reality (vibration, maintenance frequency). In mining, gasket choice is often tied to chemical exposure and service variability.

Examples can include:

CNAF (compressed non-asbestos fiber)

Spiral wound gaskets

Rubber gaskets (such as EPDM or Neoprene)

PTFE-based gaskets

To order flanges and pipe fittings for the mining industry from API International, determine your pipe size, the AWWA standard and class you need (for example, AWWA C207 Class B/D/E/F), and the material and coating requirements. Also include the service/media (process water, slurry/tailings, chemical service, etc.), and any facing and gasket preferences, especially if the line has abrasion or corrosion concerns. Contact API International’s experienced team and we will help you select the right flange for your application.

At API International, our custom manufacturing capabilities set us apart. With an in-house machine shop, we transform your designs into precision parts quickly. From single prototypes to full production runs, we deliver cost‑effective pricing, dependable performance, and rapid turnaround. Flexible material options and rigorous quality checks ensure consistency from part to part.

99.5% order accuracy rate

Our boots-on-the-ground approach ensures close collaboration with our suppliers. Every flange, valve, and fitting undergoes rigorous inspection and thorough documentation, ensuring consistent performance and reduced field issues.

Active customers in all 50 states + Canada and Mexico

When your schedule is on the line, knowing our U.S. warehouses are stocked and orders ship same-day gives you peace of mind, so you can focus on the task at hand, not the clock.

700+ machined-to-spec parts created each year

Collaborate directly with our engineers to bring your unique specifications to life, ensuring every component performs as if it were built with your project in mind.

1,500+ unique customers served over 45+ years

Our dedicated account team partners with you from quote to delivery, answering questions and offering expert advice so you can make confident decisions and avoid costly delays.