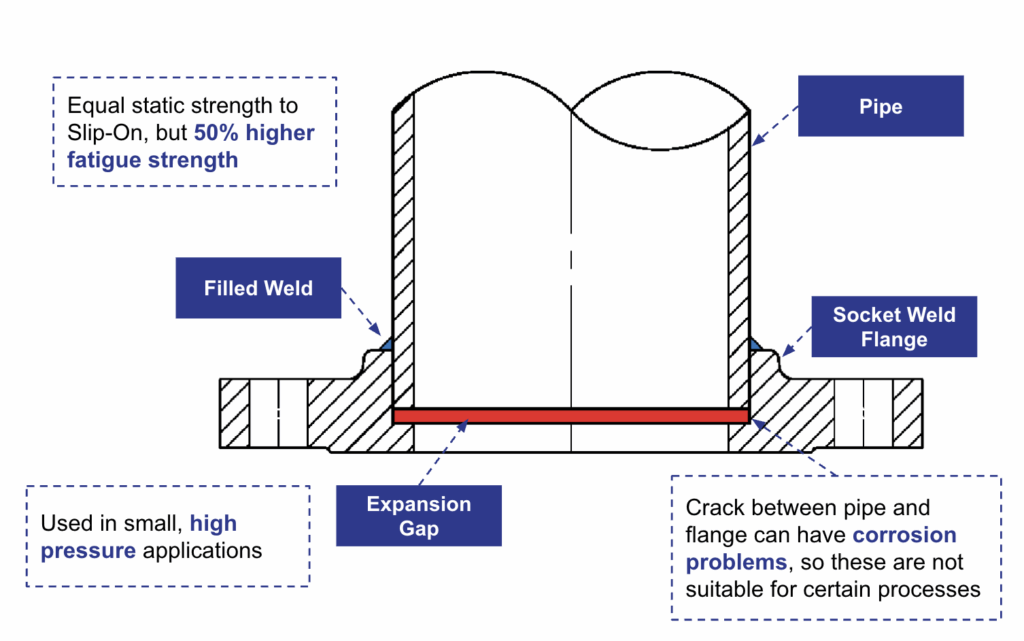

Socket weld flanges, sometimes called counterbore flanges, are a type of pipe flange designed with a recessed area, or socket, inside the bore. This socket allows a pipe to be inserted into the flange before being welded around the hub. This type of flange creates a strong and reliable connection. Also, because of this design, socket weld flanges are typically used for small diameter and high-pressure piping. This helps minimize the risk of leakage. The construction of socket weld flanges ensures proper alignment of the pipe and provides a smooth flow path, which reduces turbulence and erosion inside the system.

Compared to slip-on or weld neck flanges, socket weld flanges require less space and are easier to install in tighter configurations. They will be an excellent choice when compact, high-integrity joints are needed.

Socket weld flanges are manufactured according to international standards. The most common standards are ANSI/ASME B16.5 for sizes up to 24 inches and ANSI/ASME B16.47 for larger diameters. These standards cover dimensions, pressure-temperature ratings, tolerances, and marking requirements.

| Pressure Class | Flange OD | Hub Bore ID | Flange Thickness |

|---|---|---|---|

| 150 | 3.5″ – 20.5″ | 0.5″ – 14″ | 0.56″ – 1.75″ |

| 300 | 3.88″ – 23.5″ | 0.5″ – 14″ | 0.62″ – 2.12″ |

| 600 | 4.25″ – 25.5″ | 0.5″ – 14″ | 0.75″ – 2.5″ |

| 900 | 5″ – 27.5″ | 0.5″ – 14″ | 0.88″ – 3″ |

| 1500 | 5.75″ – 30″ | 0.5″ – 14″ | 1.12″ – 3.62″ |

| 2500 | 6.75″ – 32.5″ | 0.5″ – 14″ | 1.38″ – 4.25″ |

* Exact dimensions depend on ANSI/ASME B16.5 or B16.47 standards and the specific pipe size.

Used in systems where small-diameter pipes carry high-pressure fluids.

Ideal for thermal systems that demand secure connections to handle temperature cycling and vibration.

Used in process plants to ensure tight, dependable seals that help stop leaks of hazardous or high-value fluids.

Suitable for compact systems that require robust fittings to maintain pressure without frequent maintenance.

Provide solid connections for clean or treated water flow, minimizing the risk of leaks in pressurized setups.

This flange has a smooth, flat surface that pairs with full-face gaskets and creates an even seal for low-pressure or general service applications.

It has a slight raised area around the bore to concentrate gasket load, which improves sealing performance in medium to high-pressure systems.

Designed with a machined groove for a metal ring gasket, this face type delivers a tight, secure seal for high-pressure and high-temperature service.

A socket weld flange is a type of pipe flange where the pipe sits in a recessed area (socket) of the flange and is then fillet welded around the hub. This design ensures smooth bore flow and strong structural integrity.

Socket weld flanges offer high resistance to pressure and temperature, require less welding than butt weld types, and are easy to align during installation. They’re also available in a wide range of sizes and pressure classes.

Socket weld flanges can be more expensive due to the need for precise welding equipment and skilled labor. They also require special tools and technical expertise for proper installation. In some systems under extreme pressure or with corrosive media, maintaining long-term stability may be challenging, potentially leading to more frequent inspections or maintenance.

To install, insert the pipe into the socket until it bottoms out, then back it off slightly to allow for thermal expansion. Perform a fillet weld around the pipe at the hub. Proper gap and weld quality are very important for long-term performance.

To order socket weld flanges from API International, determine your required pipe size, pressure class, material, and any special standards (such as ASME B16.5). Contact API International’s experienced team, who will help you select the right flange for your application.

• Custom Bolt Holes, Overbore, Counterbore, Tapped, Welds, O-ring Grooves, Threads, Special Serrations, Bevels, Chamfers

• Metric Parallel, Metric Tapered, Parallel (BSPP), Taper Thread (BSPT), UN/UNF/UNC Thread, NPT (National Pipe Thread)

• MWD

• Contact API’s engineering department for exact specifications and tolerances.

Plastic: Delrin, POM, Lexan, Nylon 66, Nylon 6, PEEK, PP, PE, Acetal

Rubber: EPDM, Neoprene, Buna-N, Viton

Aluminum: A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075

Copper: 3600, 3604, 3771

Titanium: 1-28

Steel Series:

• Ductile Iron: ASTM A536

• Carbon/Mild Steel: A105, A36, A516-70, A572-50, etc.

• Stainless Steel:

- 300 Series – 303, 304, 304L, 316, 316L

- 400 Series – 420J2, 430, 434, 442

Special Metals: Hastelloy, Inconel, Incoloy, Duplex 2205, Super Duplex 2507, Chrome Steel, alloys, or their equivalents

Stock Finish, Spiral Serrated (Phonographic), Concentric Serrated, Smooth Finish, Cold Water Finish, MWD, Phonographic

Dipped, Nickel Plating, Zinc Plating (clear, yellow, black, red, blue), Super Agitine, Powder, Painted, Galvanized, Epoxy, Lacquer

Water/Wastewater, Irrigation, Agriculture, HVAC, Marine, Exhaust, Mining, Energy/Power Generation/Oil

• Forged:

- Ring Rolling:

• Materials: Carbon Steel, Stainless Steel, Duplex

• Size: 2–202”

• Cast:

- Centrifugal Casting (Industrial):

• Material: Stainless Steel

- Continuous Casting:

• Material: Stainless Steel

- Sand Casting:

• Material: A536, Stainless Steel, Ductile Iron

- Investment/Lost-Wax/Precision Casting

• Material: Stainless Steel

Machining: Milling, Turning, Facing, Boring, Drilling, Tapping, Counter Sinking, Laser Cutting, Water Jet, Plasma Cutting

| Products | Type | Materials | Size Range |

|---|---|---|---|

| Flanges | Flat-Face, Raised-Face, & Plate: Slip-On/Ring Weld, Neck, Blind, Socket Weld, Orifice, Reducing, Threaded | See Materials List | 5–202″ |

| Gaskets | Molded, Extruded, sheet | EPDM, Buna-N, NBR, Non-Asbestos (GNA), Red Rubber (GRR), Viton | 5–60″ |

| Screens For Filters | Basket Screens and Cone Screens (Perforated, Mesh) | Galv. Carbon Steel, Carbon Steel, Stainless Steel | 6”D x 8’-H |

| Rings | Exhaust Rings (Marmon Flanges for DPF Filters) | Carbon Steel, Stainless Steel, Aluminum | 1–16” |

| Seamless Rolled Rings | Forged | Carbon Steel, Stainless Steel, Aluminum | 1–165” |

| Square Hole Rings | Repair Couplers | Carbon Steel, Stainless Steel, Galvanized, Epoxy Coated | 3–32” |

| Fabricated Assemblies | Weldments, Pipe Spools, Valve Bodies, Silencer Housings | Carbon Steel, Stainless Steel | 2–24” |

| Long/Short Radius Elbows | EN 10253-2–S235, P235GH–P265GH–P265NL and ASTM A234, WPB, WPC/ A420 WPL6, WPL3/ A860 WPHY52/ ASTM A234 WP11, WP22, WP5, WP9–16Mo3 | 304L & 316L Stainless Steel | (45° & 90°): OD: 21.3mm (1/2”)–3048mm (120”) WT: Up to SCH. XXS/160 |

| Miscellaneous | Tubesheets / Diffuser Plates / Baffles / Ferrules / Sleeves / Pins | Carbon Steel, Stainless Steel, Duplex | 5–104” |

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews