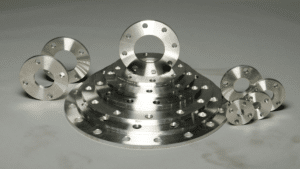

When it comes to piping system needs, there’s more to consider than flanges alone. Other articles in our Resource Center cover flanges, but this article covers the other fittings used in a piping system. Pipe fittings and connectors are integral pieces of a complete system. Each pipe fitting or accessory must meet specific requirements for proper function. These specifications may include temperature or pressure limits, size, connection type, and material. To decide which pipe fitting you need, refer to these basic guidelines.

What Are Pipe Fittings For?

Pipe fittings and pipe connections join runs of pipes together and are used to adapt piping systems by lengthening the run or changing the flow direction. Pipe fittings and accessories are used across a variety of applications and industries, including industrial HVAC, water supply, power generation exhaust, and irrigation.

What are the Different Types of Pipe Fittings?

Pipe fittings are needed to attach pipes together, and the type of fitting used is determined by the application. As every piping system is different, the pipe fittings and accessories you need may vary in material, size, or application requirements. When choosing your pipe fittings, consider your application needs: Are you extending the piping system, changing directions, reducing flow, or creating a branch? Explore these fittings and their uses:

Elbow fittings are generally available in 22.5-degree, 45-degree, and 90-degree angles and are used to change flow direction. Elbow fittings are generally available in 22.5-degree, 45-degree, and 90-degree angles and are used to change flow direction. |  A Tee creates a branch to manage flow. This fitting is T-shaped and features inward flow from one direction that splits into two directions. It may also combine flow from multiple branches into one. A Tee creates a branch to manage flow. This fitting is T-shaped and features inward flow from one direction that splits into two directions. It may also combine flow from multiple branches into one. |

Valves are used to regulate or stop the flow within a piping system. Valve types include butterfly valves to throttle or isolate flow, check valves to prevent reverse flow and pressure relief valves, which relieve system pressure. Valves are used to regulate or stop the flow within a piping system. Valve types include butterfly valves to throttle or isolate flow, check valves to prevent reverse flow and pressure relief valves, which relieve system pressure. |  A Cap is used to cover the end of a pipe. Some caps, such as exhaust rain caps, are used to block dirt, debris, and moisture from entering the piping system, while grooved caps install quickly and meet specifications for high-pressure applications. A Cap is used to cover the end of a pipe. Some caps, such as exhaust rain caps, are used to block dirt, debris, and moisture from entering the piping system, while grooved caps install quickly and meet specifications for high-pressure applications. |

Adapters, such as flange adapters or nipple adapters, are used to connect different types of pipe. An adapter may create a threaded connection on a non-threaded pipe end, while a flange adapter can be used to create a connection between non-flanged pipes or between different types of flanges. Adapters, such as flange adapters or nipple adapters, are used to connect different types of pipe. An adapter may create a threaded connection on a non-threaded pipe end, while a flange adapter can be used to create a connection between non-flanged pipes or between different types of flanges. |  A Coupling joins pipes or pairs with other fittings to create branched extensions or to create a maintenance access point. When choosing compatible pipe system components, the coupling’s pressure rating and specifications will affect overall performance A Coupling joins pipes or pairs with other fittings to create branched extensions or to create a maintenance access point. When choosing compatible pipe system components, the coupling’s pressure rating and specifications will affect overall performance |

Gaskets serve to create seals to prevent the entrance or escape of fluids from a piping system. Gasket compounds are chosen based on the intended application to ensure the properties and chemical resistance are suitable. Gaskets serve to create seals to prevent the entrance or escape of fluids from a piping system. Gasket compounds are chosen based on the intended application to ensure the properties and chemical resistance are suitable. |

How to Choose Pipe Fittings

Your pipe fittings must meet the requirements of the job, offer the appropriate connection type, and fit the pipes you’re connecting. While standard connections and types may be suitable for your application, we are also able to manufacture custom pipe fittings or alter existing stock to create the fittings and accessories necessary. The following discusses some of the key considerations when choosing a pipe fitting.

Standards or Codes

Refer to standards or codes regarding pressure-temperature ratings, required materials, fitting dimensions, or tolerances for fittings used within your piping system. Some connections and fittings, such as threaded connections, require sealant for a leak-free seal.

Standards that may apply to your pipe fittings include:

- American Water Works Association (AWWA) standards applied to pipe fittings include AWWA C606-06, which covers pipe fittings and components intended for water service.

- The American National Standards Institute (ANSI) is a United States standard for pipeline flanges and also applies to threaded, flanged, and butt or socket welded pipe fittings.

- National Standard Pipe Thread (NPT) standards dictate screw thread requirements for threaded pipes and fittings to ensure sufficient sealing for fluid, gas, or steam transport.

- American Society for Mechanical Engineers (ASME) includes codes and standards intended for pipe fittings, including cast iron flanged and threaded fittings and forged steel socket-weld and threaded fittings.

- American Society for Testing and Materials (ASTM) specifies the materials, pressure rating, and intended use of pipes, fittings, and valves, as well as dimensions and tolerances within a piping system.

- Deutsches Institut für Normung (DIN) standards cover a range of applications, including industrial, oil, and gas.

What Pipe Fitting Materials Are Best?

The pipe fitting material must be compatible with the rest of the piping system and should be rated for use with the intended application, temperature, pressure level, and liquid, gas, or solid being transported. Pipe fitting material is most often matched to the pipe or flange material. If your piping system is steel, pipe fittings are generally steel as well. Likewise, stainless steel fittings are paired with stainless steel pipes.

Consider Pipe Fitting Connection Type

Threaded connections, one of the most common connection types, include female x female, male x male, or male x female. NPT threaded connections are designed to pull tighter as the threads taper, preventing leaks in piping systems.

Flanged connections are manufactured to ANSI, ASME, DIN, and other industry standards for pressure/temperature ratings and other specifications.

Grooved connections are a reliable pipe fitting option. Grooved pipe fittings and accessories are available in rolled or cut groove styles and are suitable for a variety of wet and dry applications.

Welded connections—including socket weld and butt weld—offer increased strength and leakage prevention. These welded connections can be used in place of threaded connections in some circumstances for a tighter, more leak-proof fit.

How to Measure for Pipe Fittings

If you choose the wrong size, the pipe fittings won’t match and your seal will not be sufficient. When choosing a threaded connection, consider NPT (National Pipe Thread) standards as defined by ANSI/ASME to determine the appropriate size and specifications. National Pipe Thread is the American standard thread, which indicates the taper rate (change of diameter) along the threaded distance.

To measure for the appropriate threaded fitting, measure the Outside Diameter (OD) of your connecting pipe for male threads, or the Inside Diameter (ID) for female threads. Then, refer to the sizing chart on the product page to find the appropriate size to fit your pipe. Other considerations include end-to-end length, wall thickness, and Nominal Pipe Size (NPS).

Be aware: The OD of an NPT fitting is not the same as the Nominal Pipe Size. An NPS of 4 inches does not mean it pairs with an OD of 4 inches—for this reason, it is important to consider all measurements and refer to the product’s sizing table.

If you can’t find the right fitting, contact us to have custom items manufactured to your exact specifications. Our Custom Machine Shop offers short lead times and can produce a range of products to suit your specific needs.