API International is your source for top-quality industrial wholesale fittings tailored to meet the unique demands of the Marine and Maritime industry. With a commitment to excellence and precision, we take pride in supplying an extensive range of essential products, including steel flanges, expansion joints, grooved fittings, custom-machined components, and OEM solutions. Our focus on the maritime sector allows us to understand the intricate requirements of this dynamic industry, ensuring that our products not only adhere to the highest standards but also enhance the efficiency and reliability of marine operations.

Whether you’re seeking corrosion-resistant steel flanges, flexible expansion joints to withstand harsh maritime conditions or custom machined solutions for specific vessel needs, API International has you covered. Explore our comprehensive offerings and experience the synergy of cutting-edge technology, reliable performance, and unmatched customer service, all geared toward propelling the marine and maritime sector forward.

We begin by understanding your goals, whether it's reducing cost, improving quality, or launching a new product. Together, we define technical and commercial requirements to ensure full alignment from the start.

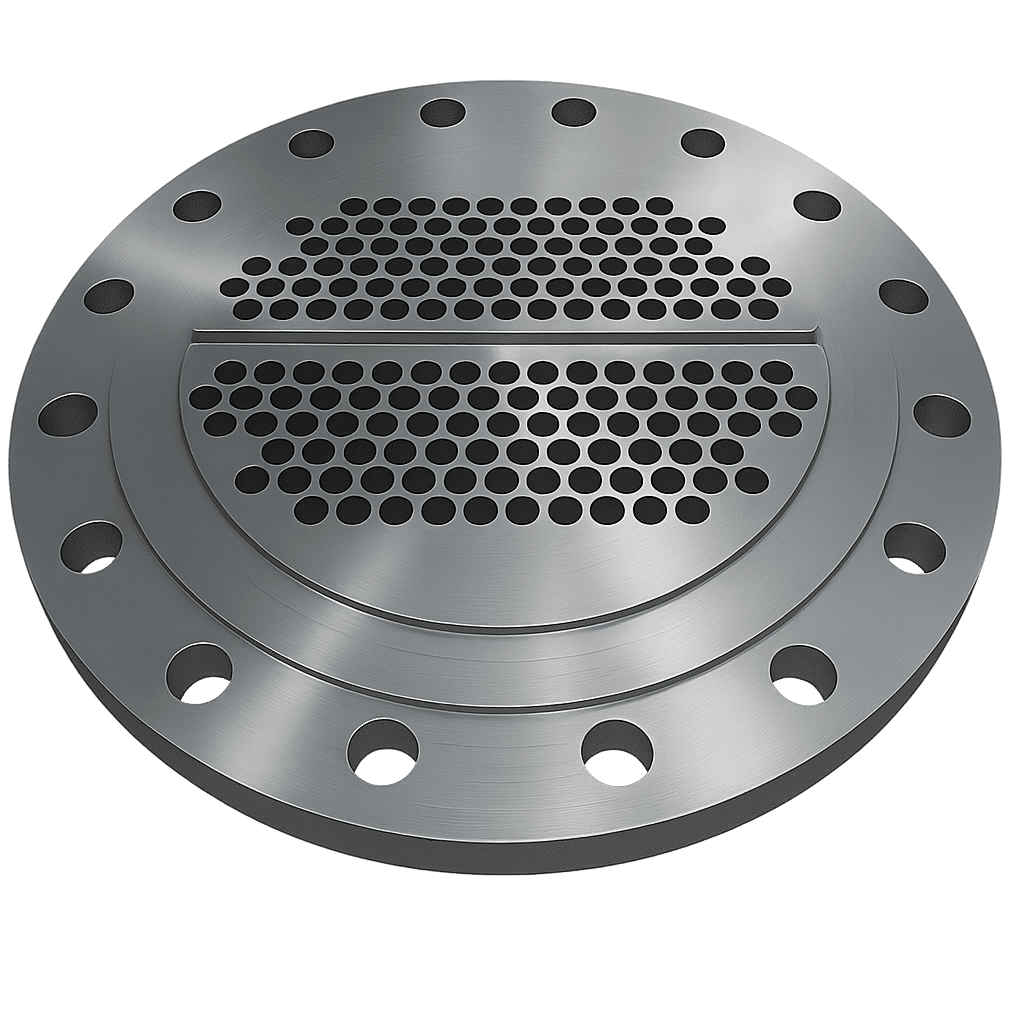

With worldwide manufacturing resources, API International provides both standard and custom flange solutions. Our network of facilities and in-house expertise allow us to deliver the right fit for your needs, whether it’s off-the-shelf or built to specification.

Our engineers work closely with customers to refine designs, reduce costs, and ensure manufacturability. We stay connected with your team throughout to keep progress clear and efficient.

After final review of samples, production begins. Our team oversees quality and delivery coordination to ensure smooth execution and traceability from start to finish.

There is no exact DIN-to-ANSI flange conversion—even if the bolt holes align, there may be a disparity between pressure ratings or other aspects of the standards. While adapters can be custom machined to facilitate matching European standard and American standard piping components, using the appropriate DIN components is a quicker, easier option.

To order marine industry flanges from API International, share your pipe size, the standard you’re using (for example, ANSI/ASME B16.5 or DIN), the pressure class/PN, and the service media (seawater cooling, ballast, fuel, lube oil, hydraulics, etc.). Also include your material and coating requirements (stainless steel, such as 304/304L or 316/316L, and black epoxy coating) and any facing and gasket preferences. If the system has saltwater exposure or corrosion concerns, mention that as well so the correct material and protection can be specified. Contact API International’s experienced team and we will help you select the right flange for your application.

At API International, our custom manufacturing capabilities set us apart. With an in-house machine shop, we transform your designs into precision parts quickly. From single prototypes to full production runs, we deliver cost‑effective pricing, dependable performance, and rapid turnaround. Flexible material options and rigorous quality checks ensure consistency from part to part.

99.5% order accuracy rate

Our boots-on-the-ground approach ensures close collaboration with our suppliers. Every flange, valve, and fitting undergoes rigorous inspection and thorough documentation, ensuring consistent performance and reduced field issues.

Active customers in all 50 states + Canada and Mexico

When your schedule is on the line, knowing our U.S. warehouses are stocked and orders ship same-day gives you peace of mind, so you can focus on the task at hand, not the clock.

700+ machined-to-spec parts created each year

Collaborate directly with our engineers to bring your unique specifications to life, ensuring every component performs as if it were built with your project in mind.

1,500+ unique customers served over 45+ years

Our dedicated account team partners with you from quote to delivery, answering questions and offering expert advice so you can make confident decisions and avoid costly delays.